A cooling method for a planetary pipe mill

A technology of planetary pipe rolling mill and cooling method, which is applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the problems of low cooling efficiency, insufficient cooling intensity, and cooling liquid injection, etc., to improve cooling efficiency and increase production , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

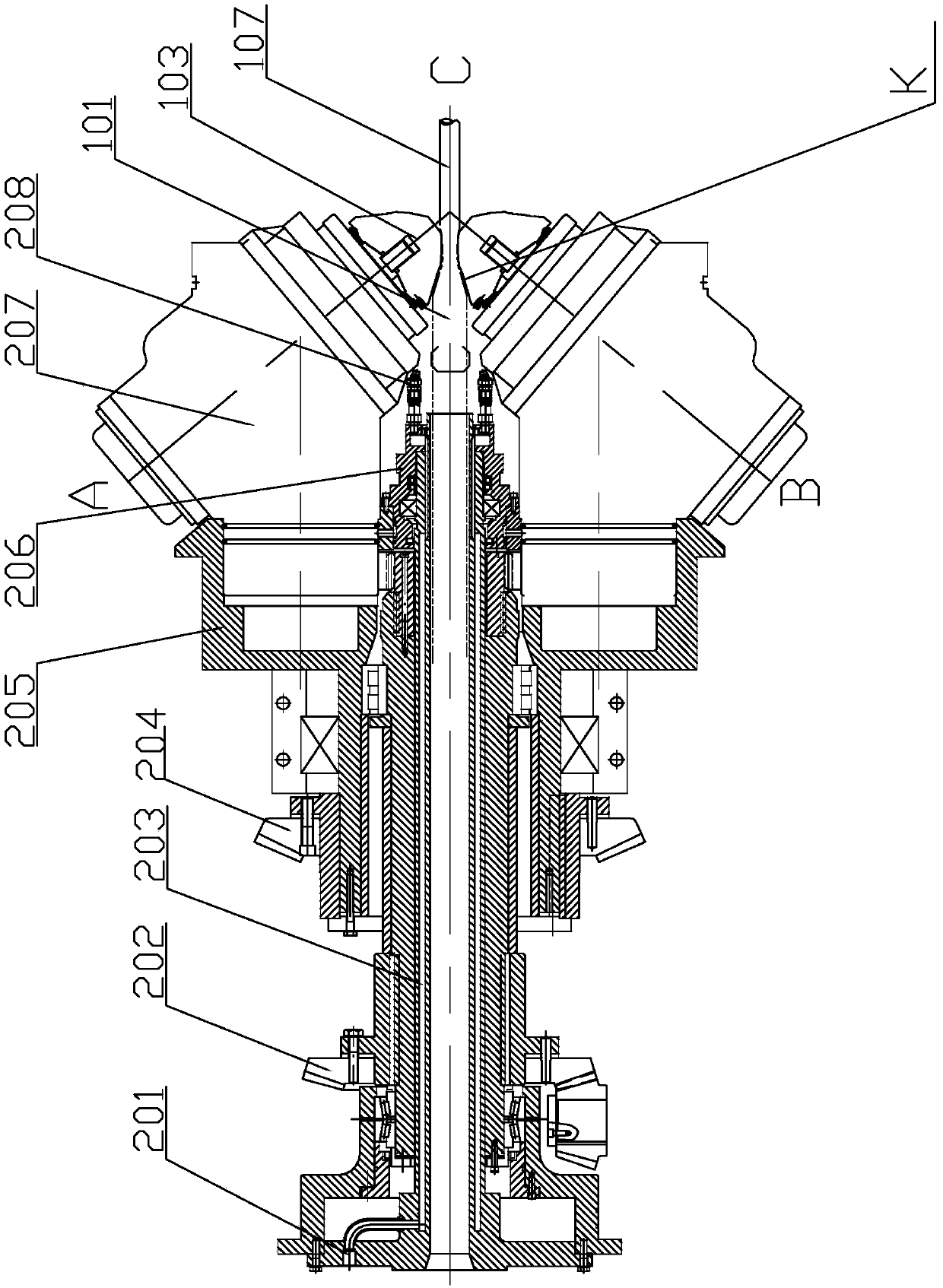

[0037] figure 1 A schematic diagram of a device for applying the method of the present invention is given.

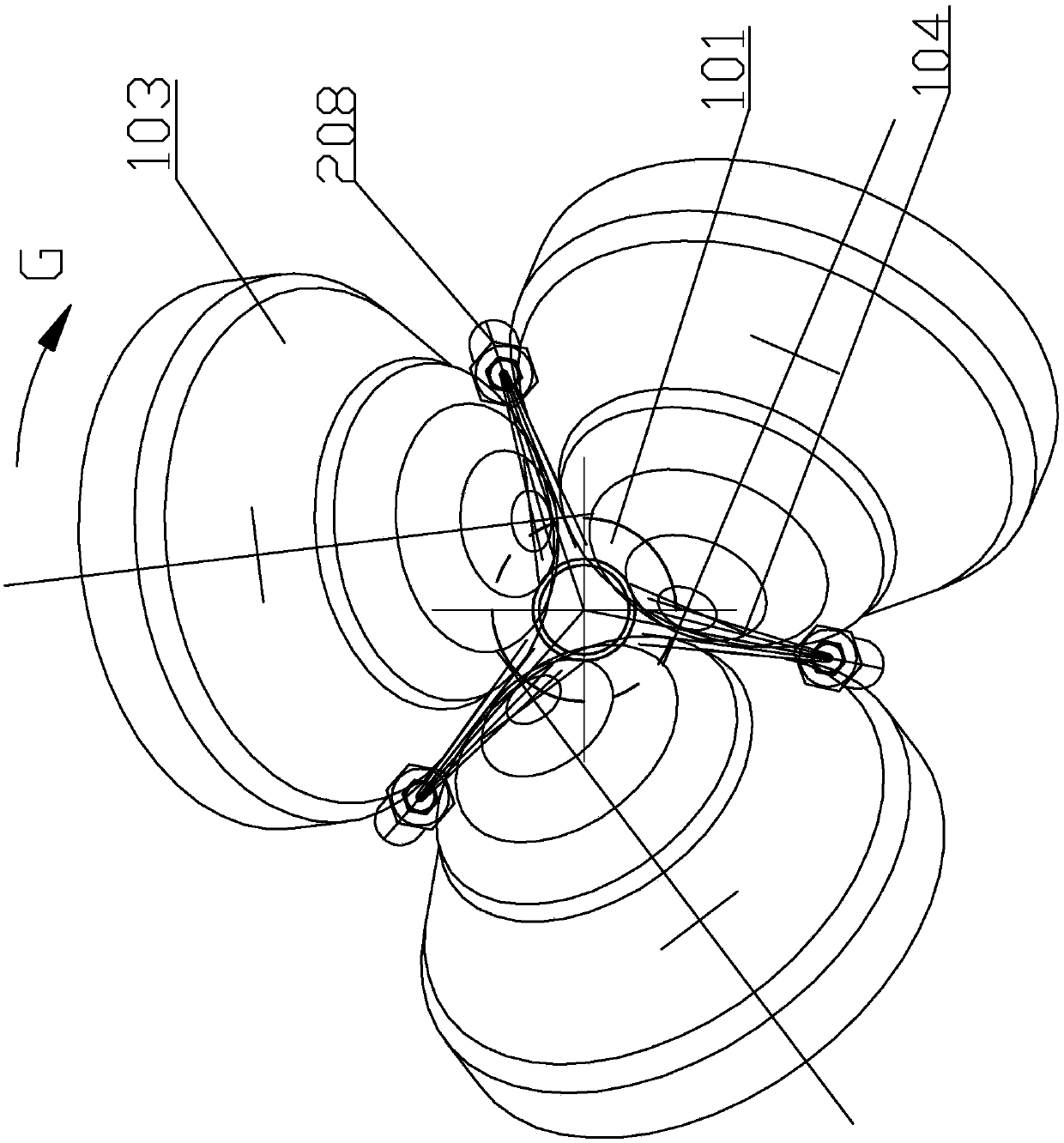

[0038] Depend on figure 1It can be seen that the main and auxiliary motors (not shown in the figure) of the planetary pipe mill respectively drive the main bevel gear 204 and the auxiliary bevel gear 202 to rotate, and the main bevel gear 204 drives the rotary body 205 to rotate. Three roll stands 207 are housed on the rotary body 205, and roll 103 is housed on the roll stand 207. During pipe rolling, driven by the main and auxiliary motors, the rotator 205, the roll stand 207 and the rolls 103 revolve around the rolling center line C-C. At the same time, the roll 103 also rotates on its own axis AC or BC.

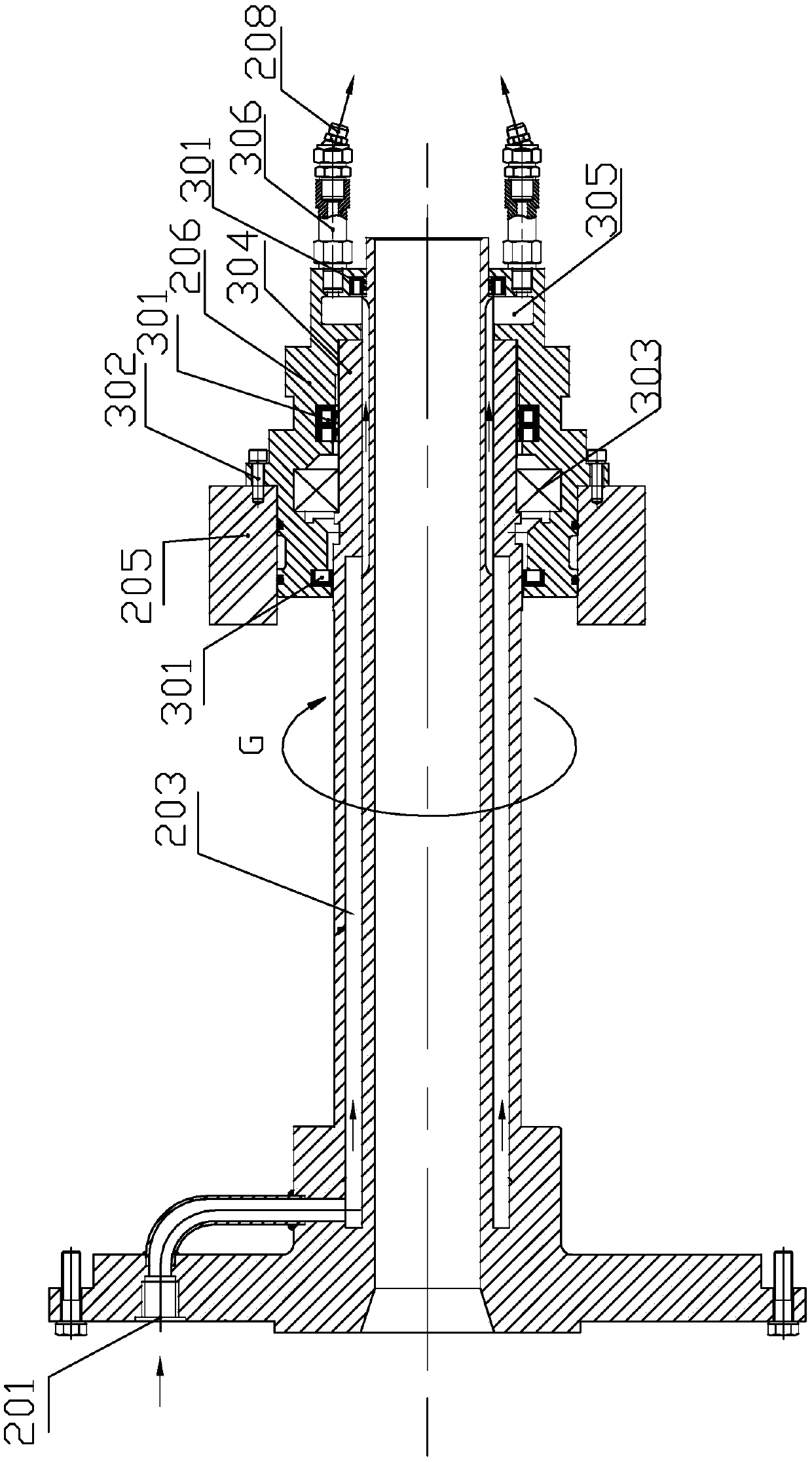

[0039] figure 1 It can also be seen that the cooling water enters from the cooling water inlet 201 at the entrance of the rolling mill, enters the water spray assembly 1 206 through the water jacket 1 203 of the central pipe of the rolling mill, and is connec...

Embodiment 2

[0047] Figure 4 A schematic diagram of Embodiment 2 is given. The difference from the first embodiment is that in the second embodiment, the rolling deformation zone K and / or the roll 103 are cooled by rotation at the exit part of the rolling mill.

[0048] The outlet nozzle seat 410 is fixed on the protective cover (not shown in the figure) of the rolling mill. The protective cover of the mill is fixed to the ground. The second water spray assembly 405 is installed on the outlet nozzle seat 410 through the second bearing 404 . The right side of the water spray assembly 2 405 is connected with the water inlet ring 409, the water inlet ring 409 is provided with a cooling water inlet 2 407, the cooling water inlet 407 is connected with the water jacket 2 406 and the sealing water chamber 2 in the water spray assembly 2 405 403 is connected. The left side of the water spray assembly 2 405 is a rotating spray plate 411, and a group of small holes are opened on the rotary spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com