Anti-sagging quick-drying two-component polyurethane waterproof paint as well as preparation method and application thereof

A two-component polyurethane and polyurethane waterproofing technology, used in polyurea/polyurethane coatings, roof insulation materials, building components, etc., can solve problems such as inability to expose the waterproof layer, long product construction delivery cycle, and long product maintenance cycle. , to achieve excellent UV aging resistance, improve sag resistance, and improve flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

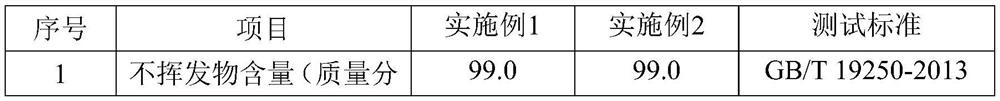

[0040]An anti-sagging and quick-drying two-component polyurethane waterproof paint of the present invention is composed of component A and component B with a mass ratio of 1:1.5; wherein component A is prepared from the following raw materials in parts by weight: 50 parts of PTMEG1000, 15 parts of PTMEG2000, 30 parts of IPDI, 4.45 parts of HC-180 plasticizer, 0.05 part of DY-20 catalyst and 0.5 part of 1,4 butanediol; component B is prepared from the following raw materials in parts by weight: 5 parts of JQN-405, 30 parts of F420, 10 parts of HC-180 plasticizer, 25 parts of R996 titanium dioxide, 25 parts of 3000 mesh precipitated barium sulfate, 1.4 parts of BENTONE 38, 0.5 parts of defom 6800, 0.5 parts of soft carbon black, 0.5 parts of BYK-306, 0.5 parts of disponer904s wetting and dispersing agent, 1.5 parts of Crayvallac MT, 0.1 parts of dibutyltin dilaurate.

[0041] The preparation method of the anti-sag quick-drying type two-component polyurethane waterproof paint of ...

Embodiment 2

[0046] An anti-sagging and quick-drying two-component polyurethane waterproof paint of the present invention is composed of component A and component B with a mass ratio of 1:1.75; wherein component A is mainly prepared from the following raw materials in parts by weight : 25 parts of PTMEG1000, 40 parts of PTMEG2000, 30 parts of IPDI, 0.05 part of DY-20 catalyst, 0.5 part of 1,4 butanediol, 4.45 parts of HC-180 plasticizer; B component is prepared from the following raw materials in parts by weight : 3 parts of JQN-405, 32 parts of F420, 10 parts of HC-180 plasticizer, 25 parts of R996 titanium dioxide, 25 parts of 3000 mesh precipitated barium sulfate, 1.4 parts of BENTONE 38, 0.5 parts of defom 6800, 0.5 parts of soft carbon black , 0.5 parts of BYK-306, 0.5 parts of disponer904s wetting and dispersing agent, 1.5 parts of Crayvallac MT, 0.1 parts of dibutyltin dilaurate.

[0047] The anti-sagging quick-drying type two-component polyurethane waterproof paint preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com