Production process of a high-weight non-woven Tibetan blanket

A production process and blanket technology, which is applied in the production process of high-weight non-woven blankets, can solve problems affecting the quality of blankets and the impact of chemical residues on blankets, so as to improve material use efficiency and reduce material costs , high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

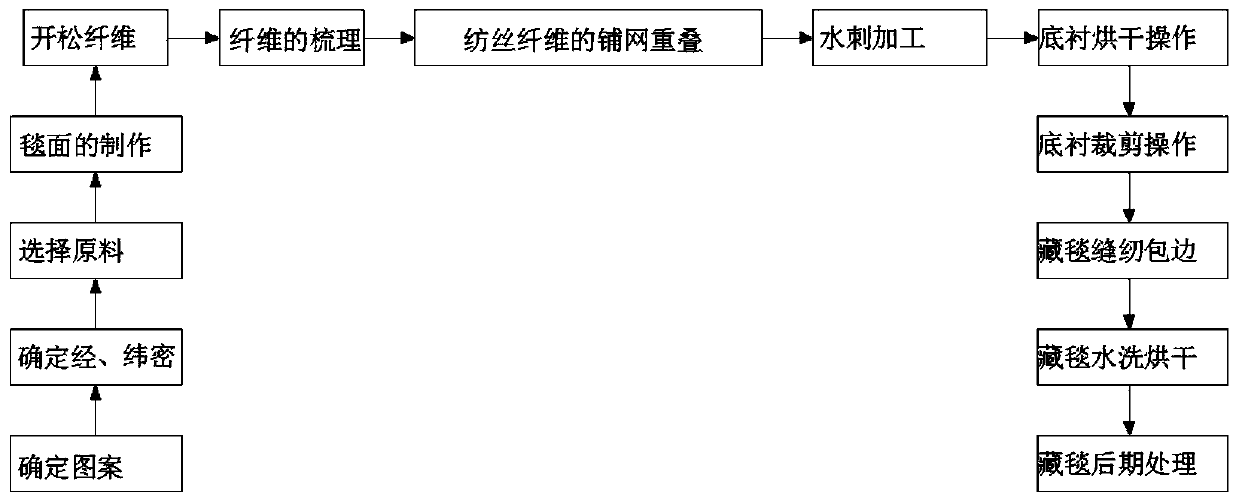

[0055] A production process of a high-grammage nonwoven Tibetan blanket, comprising the following steps:

[0056] 1) Determine the pattern required for the Tibetan carpet, and then use the computer to design the color and pattern of the Tibetan carpet;

[0057] 2) Determine the warp density and weft density of the Tibetan carpet, the warp density is 300, and the weft density is 1000;

[0058] 3) Nylon, polypropylene, polyester, wool and viscose fibers are selected as raw material yarns, and the corresponding color is selected according to the color of the required Tibetan blanket, and the yarn count parameter is 1000d;

[0059] 4) 5,000 yarns are wound and installed on the creel, and then the yarns of various colors on the creel are drawn out and connected to the loom, and the upper half of the Tibetan carpet is woven by digital management and control of the loom ,spare;

[0060] 5) placing the spun fiber used to make the backing under the state that the speed of the opening...

Embodiment 2

[0070] A production process of a high-grammage nonwoven Tibetan blanket, comprising the following steps:

[0071] 1) Determine the pattern required for the Tibetan carpet, and then use the computer to design the color and pattern of the Tibetan carpet;

[0072] 2) Determine the warp density and weft density of the Tibetan carpet, the warp density is 600, and the weft density is 2000;

[0073] 3) Nylon, polypropylene, polyester, wool and viscose fibers are selected as raw material yarns, and the corresponding color is selected according to the color of the required Tibetan blanket, and the yarn count parameter is 4000d;

[0074] 4) 8,000 yarns are wound and installed on the creel, and then the yarns of various colors on the creel are drawn out and connected to the loom, and the upper half of the Tibetan carpet is woven by digital management and control of the loom ,spare;

[0075] 5) placing the spun fiber used to make the backing under the state that the speed of the opening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com