Environment-friendly peculiar smell removing Tibetan carpet manufacturing process

A manufacturing process and environmentally friendly technology, applied in the direction of non-woven fabrics, textiles, papermaking, dyeing, etc., can solve problems such as odor pollution, instability, and non-environmental quality, to control softness and hardness, improve material use efficiency, Effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

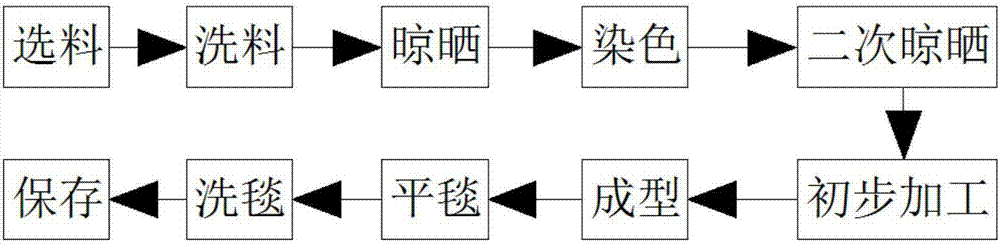

Method used

Image

Examples

Embodiment 1

[0040] An environment-friendly manufacturing process for odor-removing Tibetan blankets, comprising the following raw materials in proportions by weight: 75 parts of Tibetan wool, 6 parts of natural latex, 0 parts of yak fluff, 10 parts of sumac, 7 parts of rapeseed flowers, and 6 parts of walnut skin , 8 parts of oak shells and 17 parts of purified water.

[0041] An environment-friendly manufacturing process for odor-removing Tibetan blankets, comprising the following steps: 1) material selection, selecting 75 parts of Tibetan wool, wherein wool with the same color and luster is selected, and impurities inside the raw materials are removed.

[0042] 2) For washing materials, place the selected materials separately in the corresponding washing equipment according to their categories. The water temperature selected for the washing equipment shall not exceed 45 degrees and not lower than 30 degrees, and the cleaning time shall not exceed 30 degrees each time. For 40 seconds, wa...

Embodiment 2

[0050] An environment-friendly manufacturing process for deodorizing Tibetan blankets, comprising the following raw materials in proportions by weight: 80 parts of Tibetan wool, 7 parts of natural latex, 12 parts of yak fluff, 11 parts of sumac, 8 parts of rapeseed, and 6 parts of walnut skin , 7 parts of oak shells and 16 parts of purified water.

[0051] An environment-friendly manufacturing process for odor-removing Tibetan blankets, comprising the following steps: 1) material selection, selecting 80 parts of Tibetan wool, of which wool with the same color and luster is selected, and impurities inside the raw material are removed, and 12 parts of yak down can be added if necessary , the specific requirements are the same as Tibetan wool.

[0052] 2) For washing materials, place the selected materials separately in the corresponding washing equipment according to their categories. The water temperature selected for the washing equipment shall not exceed 45 degrees and not lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com