Pulp composite repair method and repair pulp

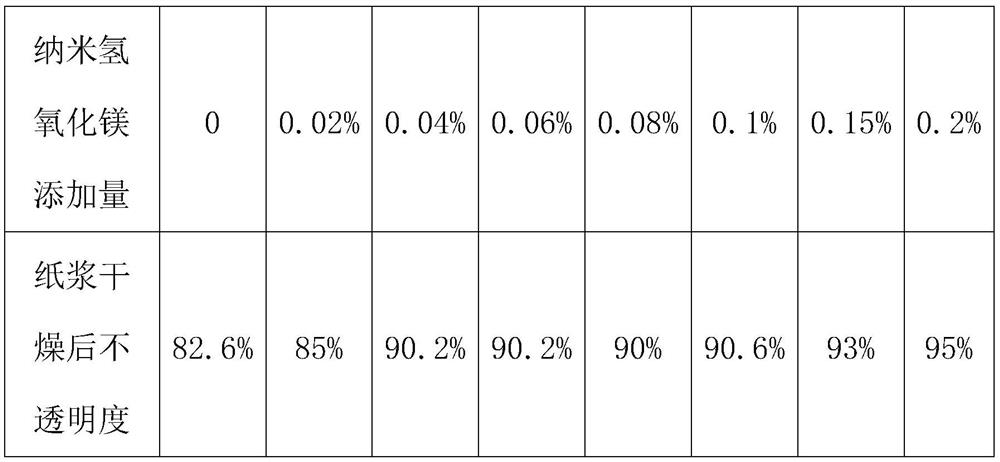

A technology of paper cultural relics and pulp, applied in non-woody plant/crop pulp, papermaking, post-processing of waste paper, etc., can solve the problems of handwriting, pigment smearing, cracking, unsuitable for repairing contemporary paper art, etc. Achieve the effects of increasing opacity, repairing stability, promoting suspension and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 30. The program lists for concerts in the period of the Republic of China are all made of machine-made paper without curtains. The paper is severely damaged, acidified, browned, and brittle, and needs to be repaired.

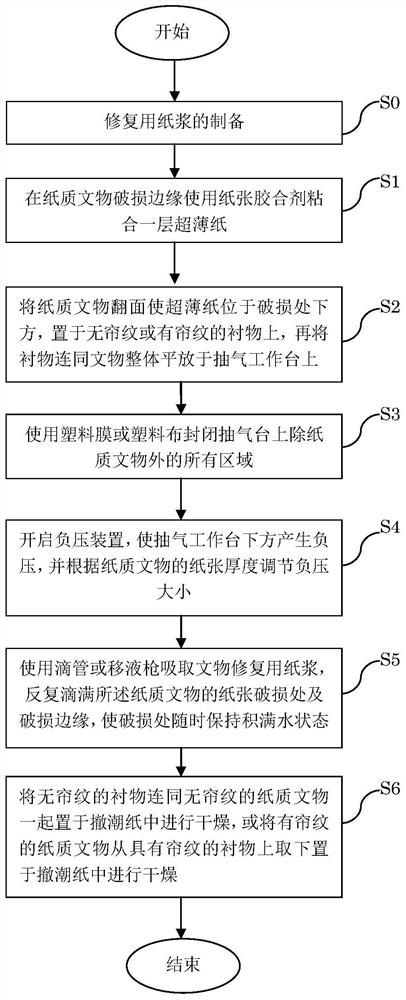

[0036] figure 1 It is a flowchart of the method for repairing fragile water-fearing paper cultural relics according to Embodiment 1-7 of the present invention.

[0037] Such as figure 1 As shown, the process flow of the repair method in this embodiment is as follows:

[0038] Step 1, use 3% sodium carboxymethylcellulose aqueous solution to bond a layer with a thickness of 0.02mm and a weight of 5g / m on the damaged edge of the paper cultural relic 2 Samsuma tissue paper;

[0039] Step 2, turn the paper cultural relics over so that the Sanya thin paper is located under the damaged part, place it on the polyester cloth, and put the polyester cloth and the paper cultural relics flat on the suction table;

[0040] Step 3, use plastic film to seal all areas...

Embodiment 2

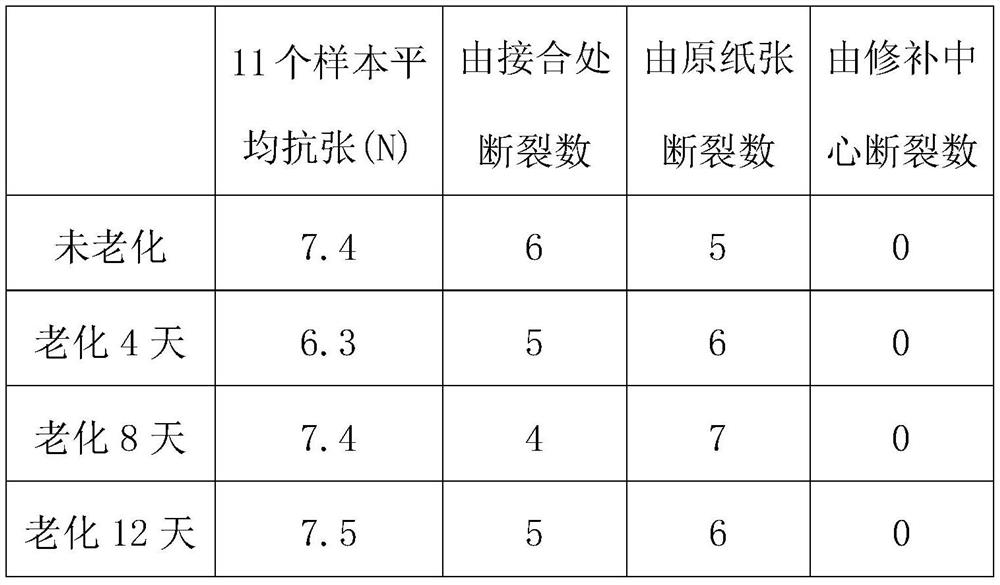

[0056] In January 1950, the late Republic of China document "The Melting Pot of the Great Era: An Introduction to East China Military and Political University" was published by the Political Department of East China Military and Political University. Use the method and material provided in Example 1 and use similar domestic traditional methods (only fill with pulp, not stick ultra-thin paper, but add the use of suction workbench) to repair respectively, and then respectively according to ISO 1924-2: 1994Paper and board-Determination of tensile properties-Part 2:Constant rate of elongation method and ISO 5626:1993Paper-Determination of Folding Endurance determine its tensile strength and folding endurance. The width of the test strip is 15mm, and the repaired part of the test strip is a square of 15mm x 15mm; the distance between the samples used for the tensile strength is 100mm, and the tensile speed is 10mm / min. After measuring the value of the test strip, take the average v...

Embodiment 3

[0061] "English Yitong" issued by Shanghai Commercial Press in May 1933 was printed on machine-made paper with a thickness of 0.11mm and no curtain grain. Its pH was 3.4 and its average tensile strength was 6.9N.

[0062] Respectively use the method provided by Example 1, materials and use similar traditional methods (only fill with pulp, do not stick ultra-thin paper, but carry out on the negative pressure of the suction workbench) to carry out repair, and then use as example 2 tensile strength and folding endurance test method for the determination of mechanical strength.

[0063] The test results are as follows:

[0064] When repaired with the traditional pulp dripping method in China, the average tensile strength of 20 test strips is only 4.7N-5.4N, and 18 test strips are broken from the edge of the repaired part (that is, the joint), showing that the repair strength is insufficient . When using the method of Example 1 to repair, the transverse average tensile strength o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com