Preparation method of polyvinylidene fluoride modified composite conductive adhesive

A polyvinylidene fluoride, composite conductive technology, applied in circuits, structural parts, electrical components, etc., can solve problems such as modification of PVDF properties, and achieve the effects of reducing polarization degree, high cycle capacity retention, and improving electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

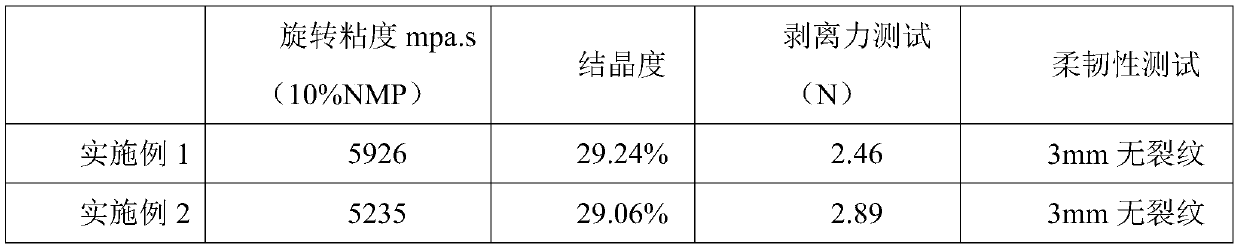

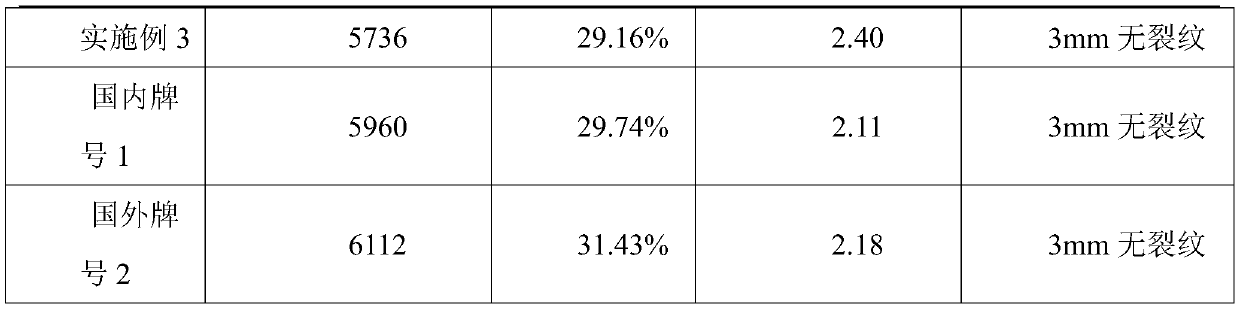

Embodiment 1

[0034] A preparation method of polyvinylidene fluoride modified composite binder for lithium ion battery, comprising the following steps:

[0035] (1) Add 500ml of polyvinylidene fluoride dispersion emulsion with a solid content of 20%wt and 10g of trifluoroethyl methacrylate (TFEMA) in a four-necked flask, wherein the emulsifier content in the emulsion is 1.25g, and nitrogen is purged to remove oxygen , stirred at 200r / min, heated to 75°C, added 0.1g initiator and 0.5g molecular weight regulator;

[0036] (2) During the reaction process, keep the polymerization temperature at 75°C, stir at a speed of 200r / min, keep the reaction for 4 hours, cool down and discharge, and wash the composite material for later use;

[0037] (3) Add 500ml of hydrochloric acid solution with a concentration of 1mol / L, 15g of aniline monomer and 85g of the composite material prepared in step (2) into a four-neck flask, ultrasonically disperse for 1h, weigh 12g of ammonium persulfate and dissolve it i...

Embodiment 2

[0039] A preparation method of polyvinylidene fluoride modified composite binder for lithium ion battery, comprising the following steps:

[0040] (1) Add 500ml of polyvinylidene fluoride dispersion emulsion with a solid content of 20%wt and 30g of trifluoroethyl methacrylate (TFEMA) in a four-necked flask, wherein the emulsifier content in the emulsion is 1.25g, and nitrogen is purged to remove oxygen , stirred at 200r / min, heated to 75°C, added 0.1g initiator and 0.5g molecular weight regulator,

[0041] (2) During the reaction process, the polymerization temperature was kept at 75° C., the stirring speed was 200 r / min, the heat preservation reaction was carried out for 4 hours, the temperature was lowered and the material was discharged, and the composite material was washed for later use.

[0042] (3) Add 500ml of hydrochloric acid solution with a concentration of 1mol / L, 15g of aniline monomer and 85g of the composite material prepared in step (2) into a four-neck flask, ...

Embodiment 3

[0044] The preparation method of polyvinylidene fluoride modified composite binder for lithium ion battery comprises the following steps:

[0045] (1) Add 500ml of polyvinylidene fluoride dispersion emulsion with a solid content of 20%wt and 10g of trifluoroethyl methacrylate (TFEMA) into a four-necked flask, wherein the emulsifier content in the emulsion is 1.25g, and nitrogen is purged to remove oxygen , stirred at 200r / min, heated to 75°C, added 0.1g initiator and 0.5g molecular weight regulator,

[0046] (2) During the reaction process, the polymerization temperature was kept at 70° C., the stirring speed was 200 r / min, the heat preservation reaction was carried out for 6 hours, the temperature was lowered and the material was discharged, and the composite material was washed for later use.

[0047] (3) Add 500ml of hydrochloric acid solution with a concentration of 1mol / L, 15g of aniline monomer and 85g of the composite material prepared in step (2) into a four-neck flask, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com