Preparation, application and mattress of a kind of bamboo spring

A bamboo and mattress technology, applied in spring mattresses, mattresses, applications, etc., can solve the problems of easy mildew or growth of bacteria and other microorganisms, poor sleep comfort, damage to bamboo structure, etc., to overcome soft and hard Small control range, improved sleep comfort, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

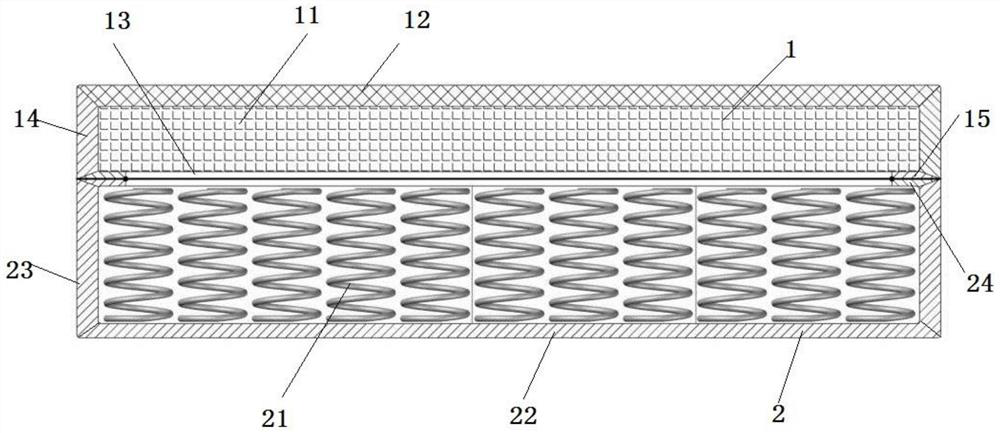

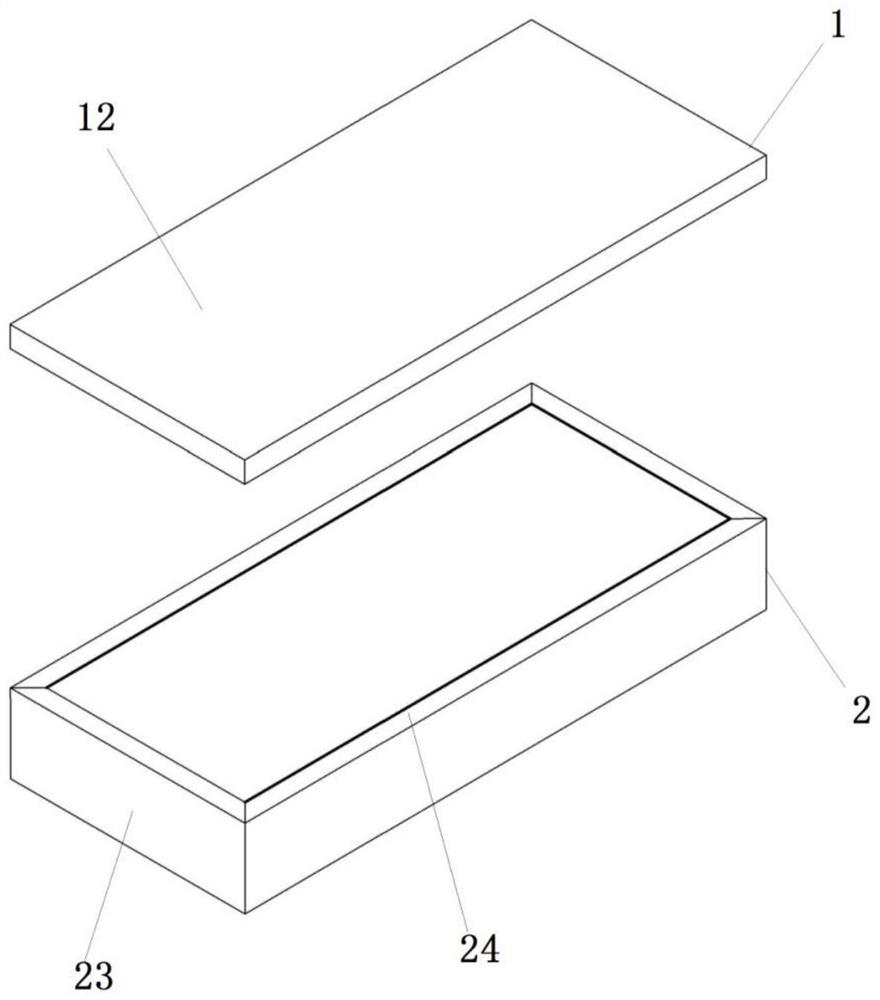

Image

Examples

Embodiment 1

[0049] The preparation method of a kind of bamboo spring of the present embodiment, comprises the steps:

[0050] 1. Sorting of raw materials

[0051] (1) Bamboo filaments are obtained from bamboo materials through a wire drawing process. The cross-sectional shapes of the bamboo filaments can be round, square, rectangular, etc. The bamboo filaments are 0.5 to 2.5 m long and 2 to 6 mm in diameter or side length.

[0052] (2) Using infrared to detect the bamboo fiber content of bamboo silk, and according to the relationship between the elastic modulus of bamboo and the volume fraction of bamboo fiber, E=40.129V f +0.2219, according to the elastic modulus (0~30GPa), the bamboo silk is divided into one grade every 5GPa, and there are six grades in total; wherein, the relationship model E=40.129V f In +0.2219, E represents the elastic modulus of bamboo silk, unit: GPa; V f Indicates the bamboo fiber volume fraction of bamboo filaments.

[0053] (3) Select the primary raw materia...

Embodiment 2

[0068] The preparation method of a kind of bamboo spring of the present embodiment, comprises the steps:

[0069] 1. Sorting of raw materials

[0070] (1) Bamboo filaments are obtained from bamboo materials through a wire drawing process. The cross-sectional shapes of the bamboo filaments can be round, square, rectangular, etc. The bamboo filaments are 0.5 to 2.5 m long and 2 to 6 mm in diameter or side length.

[0071] (2) Using infrared to detect the bamboo fiber content of bamboo silk, and according to the relationship between the elastic modulus of bamboo and the volume fraction of bamboo fiber, E=40.129V f +0.2219, according to the elastic modulus (0~30GPa), the bamboo silk is divided into one grade every 5GPa, and there are six grades in total; wherein, the relationship model E=40.129V f In +0.2219, E represents the elastic modulus of bamboo silk, unit: GPa; V f Indicates the bamboo fiber volume fraction of bamboo filaments.

[0072] (3) Select the primary raw materia...

Embodiment 3

[0087] The preparation method of a kind of bamboo spring of the present embodiment, comprises the steps:

[0088] 1. Sorting of raw materials

[0089] (1) Bamboo filaments are obtained from bamboo materials through a wire drawing process. The cross-sectional shapes of the bamboo filaments can be round, square, rectangular, etc. The bamboo filaments are 0.5 to 2.5 m long and 2 to 6 mm in diameter or side length.

[0090] (2) Using infrared to detect the bamboo fiber content of bamboo silk, and according to the relationship between the elastic modulus of bamboo and the volume fraction of bamboo fiber, E=40.129V f +0.2219, according to the elastic modulus (0~30GPa), the bamboo silk is divided into one grade every 5GPa, and there are six grades in total; wherein, the relationship model E=40.129V f In +0.2219, E represents the elastic modulus of bamboo silk, unit: GPa; V f Indicates the bamboo fiber volume fraction of bamboo filaments.

[0091] (3) Select the primary raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com