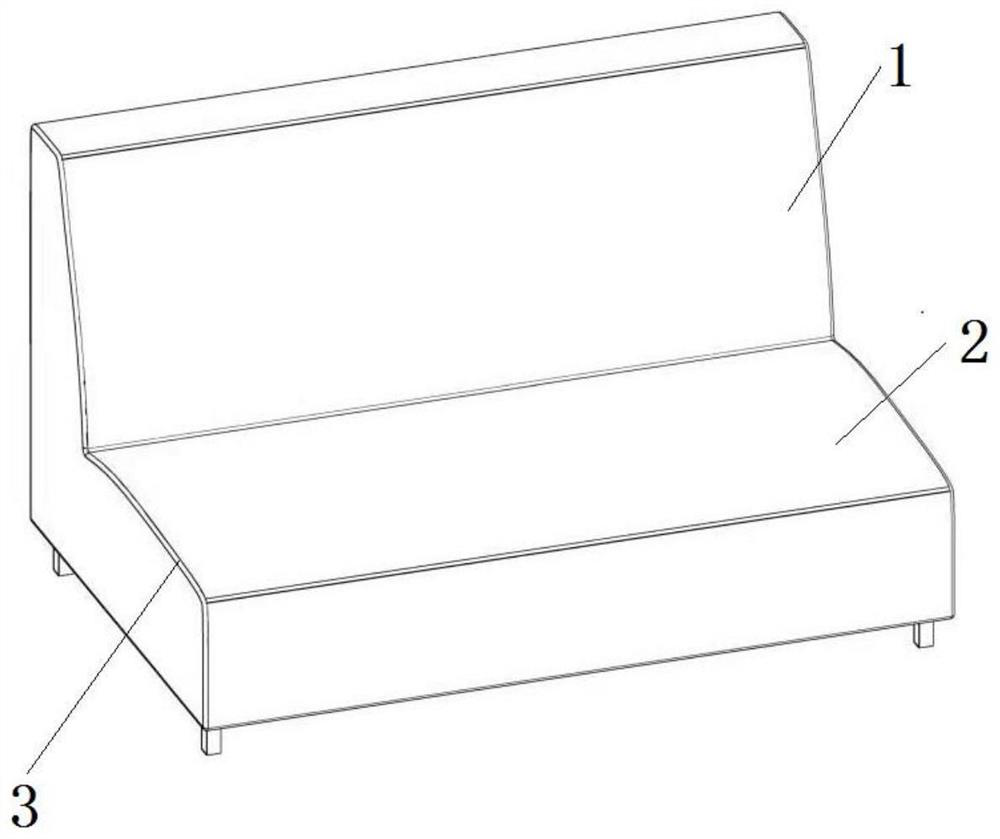

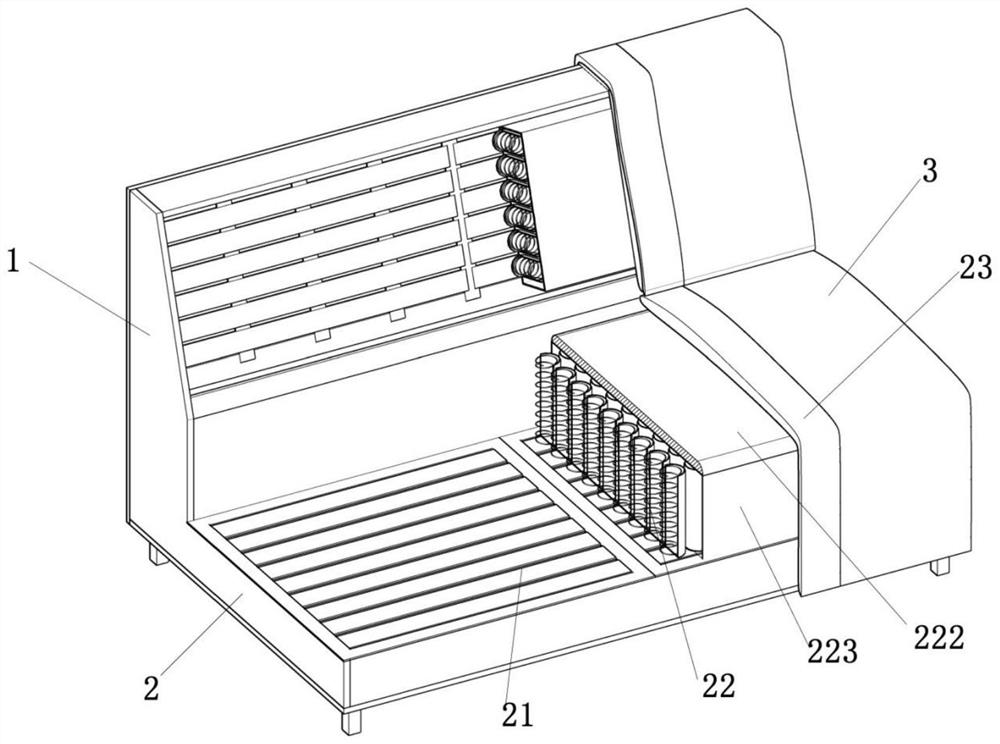

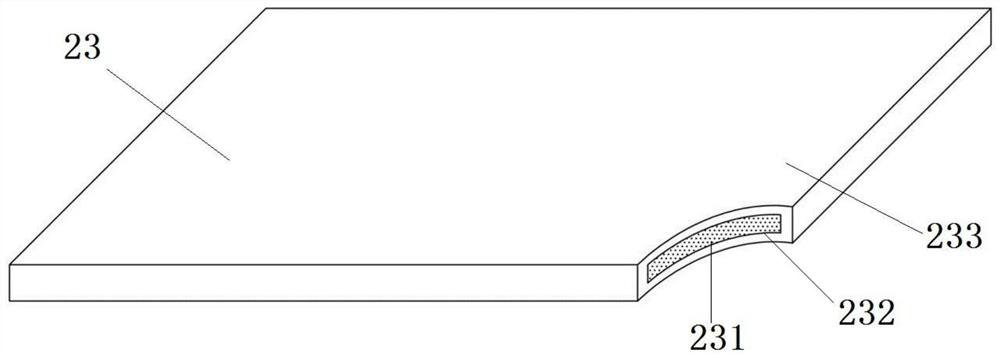

A bamboo spring sofa

A bamboo and sofa technology, applied in the field of sofa technology, can solve the problems of destroying the natural structure of bamboo, poor sitting comfort, and high hardness of the board, and achieve the effects of eliminating fatigue, overcoming poor air permeability, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation method of a kind of bamboo spring of the present embodiment, comprises the steps:

[0059] 1. Sorting of raw materials

[0060] (1) Bamboo filaments are obtained by drawing bamboo materials. The cross-sectional shape of the bamboo filaments can be round, square, rectangular, etc. The bamboo filaments are 0.5-2.5 m long and 4-7 mm in diameter or side length.

[0061] (2) Using infrared to detect the bamboo fiber content of bamboo silk, and according to the relationship between the elastic modulus of bamboo and the volume fraction of bamboo fiber, E=40.129V f +0.2219, according to the elastic modulus (0~30GPa), the bamboo silk is divided into one grade every 5GPa, and there are six grades in total; wherein, the relationship model E=40.129V f In +0.2219, E represents the elastic modulus of bamboo silk, unit: GPa; V f Indicates the bamboo fiber volume fraction of bamboo filaments.

[0062] (3) Select the primary raw materials of bamboo silk with elastic m...

Embodiment 2

[0077] The preparation method of a kind of bamboo spring of the present embodiment, comprises the steps:

[0078] 1. Sorting of raw materials

[0079] (1) Bamboo filaments are obtained by drawing bamboo materials. The cross-sectional shape of the bamboo filaments can be round, square, rectangular, etc. The bamboo filaments are 0.5-2.5 m long and 4-7 mm in diameter or side length.

[0080] (2) Using infrared to detect the bamboo fiber content of bamboo silk, and according to the relationship between the elastic modulus of bamboo and the volume fraction of bamboo fiber, E=40.129V f +0.2219, according to the elastic modulus (0~30GPa), the bamboo silk is divided into one grade every 5GPa, and there are six grades in total; wherein, the relationship model E=40.129V f In +0.2219, E represents the elastic modulus of bamboo silk, unit: GPa; V f Indicates the bamboo fiber volume fraction of bamboo filaments.

[0081] (3) Select the primary raw materials of bamboo silk with elastic m...

Embodiment 3

[0096] The preparation method of a kind of bamboo spring of the present embodiment, comprises the steps:

[0097] 1. Sorting of raw materials

[0098] (1) Bamboo filaments are obtained by drawing bamboo materials. The cross-sectional shape of the bamboo filaments can be round, square, rectangular, etc. The bamboo filaments are 0.5-2.5 m long and 4-7 mm in diameter or side length.

[0099] (2) Using infrared to detect the bamboo fiber content of bamboo silk, and according to the relationship between the elastic modulus of bamboo and the volume fraction of bamboo fiber, E=40.129V f +0.2219, according to the elastic modulus (0~30GPa), the bamboo silk is divided into one grade every 5GPa, and there are six grades in total; wherein, the relationship model E=40.129V f In +0.2219, E represents the elastic modulus of bamboo silk, unit: GPa; V f Indicates the bamboo fiber volume fraction of bamboo filaments.

[0100] (3) Select the primary raw materials of bamboo silk with elastic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com