Method for manufacturing recombined tobacco leaves through paper-making mode

A technology for reconstituting tobacco leaves and papermaking, which is applied in the preparation of tobacco, tobacco, and application, can solve the problems of single form, single substance, and cannot improve other qualities of smoke, and achieves the effect of convenient operation and scientific and reasonable method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

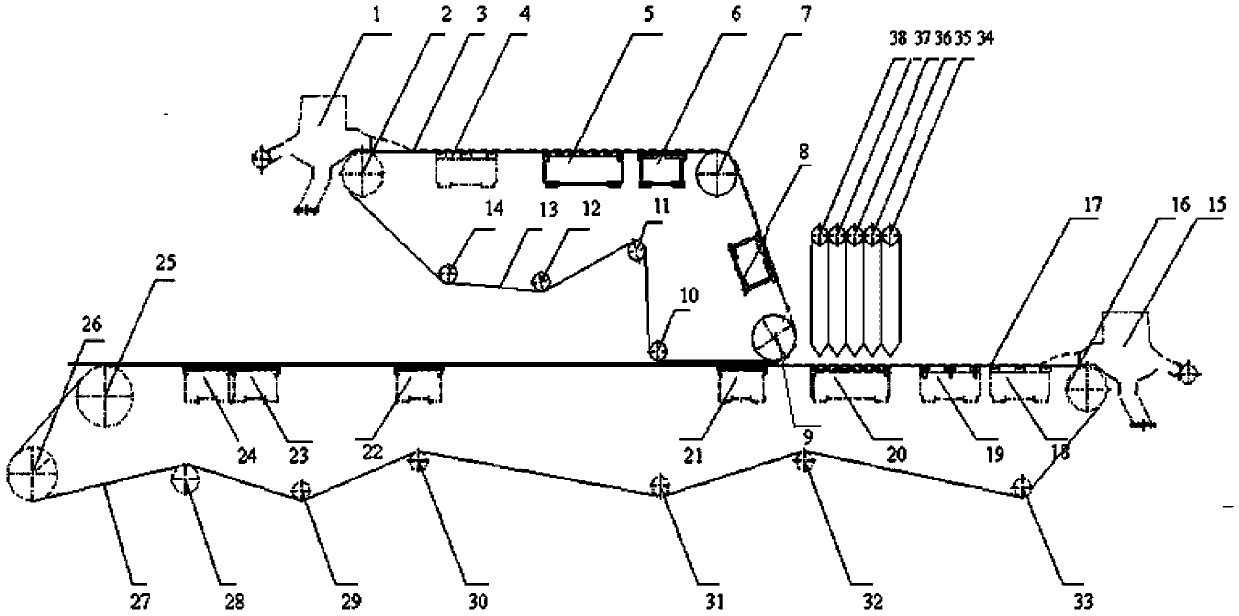

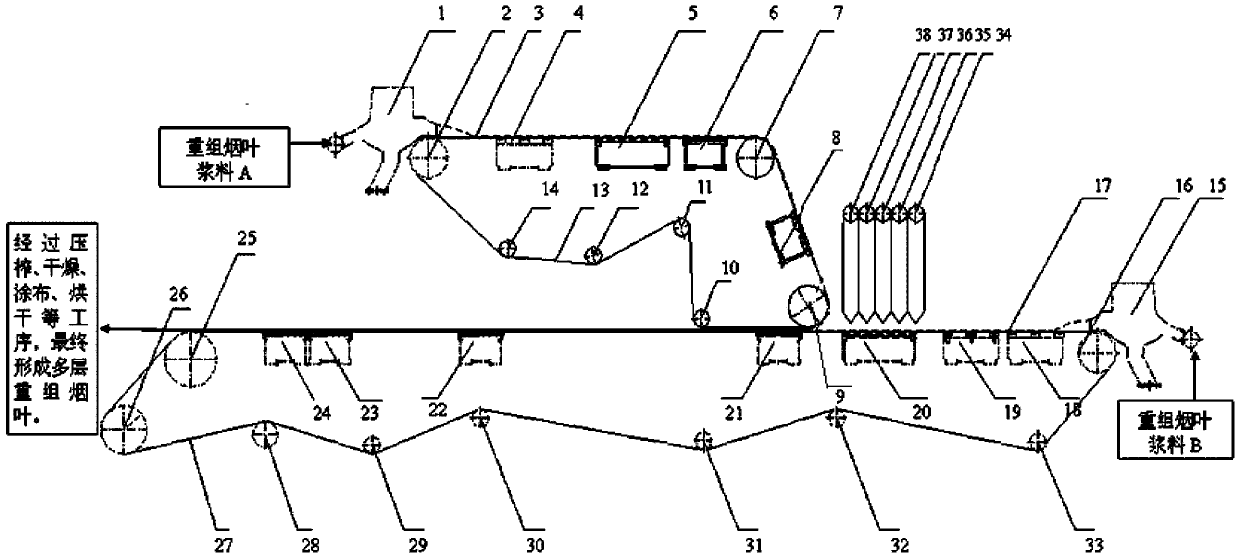

Image

Examples

Embodiment 1

[0025] (1) Preparation of pulp for papermaking of top headbox and bottom headbox substrate

[0026] The coniferous wood pulp, hardwood pulp and tobacco raw materials are mixed and beaten, and the mixed beating degree is 30 o Sr. The ratio of substrate raw materials is as follows (dry basis): 10% wood pulp, 85% tobacco pulp, and 5% calcium carbonate. Wherein, the ratio of coniferous wood and hardwood in wood pulp is 1:1. Tobacco pulp, coniferous wood pulp and hardwood pulp are mixed and pulped to a pulp concentration of 0.8%, and then divided into two parts, and the same flow is sent to the top head box and the bottom head box for papermaking. The weight of the substrate formed by the top net headbox and the bottom net is both set to 20g / m 2 .

[0027] (2) Preparation of powdered raw materials

[0028] The dried licorice is selected as the functional solid material, ground to a particle size of 40 microns by an ultrafine pulverizer, and then placed in No. 1 powdering devic...

Embodiment 2

[0033] (1) Preparation of pulp for papermaking of top headbox and bottom headbox substrate

[0034] Softwood pulp, hardwood pulp and tobacco raw materials are mixed and beaten, and the mixing degree is 55 o Sr. The ratio of substrate raw materials is as follows (dry basis): 20% wood pulp, 70% tobacco pulp, and 10% calcium carbonate. Among them, the ratio of coniferous wood and hardwood in wood pulp is 4:1. Tobacco pulp, coniferous wood pulp and hardwood pulp are mixed and pulped to a pulp concentration of 1.4%, and then divided into two parts, and the same flow is sent to the top head box and the bottom head box for papermaking. The weight of the substrate formed by the top net head box and the bottom net is set to 30g / m 2 .

[0035] (2) Preparation of powdered raw materials

[0036] Tobacco powder in packages and depitted and dried hawthorn were selected as functional solid materials, and were respectively ground to a particle size of 400 microns by using an ultrafine pu...

Embodiment 3

[0041] (1) Preparation of pulp for papermaking of top headbox and bottom headbox substrate

[0042] The coniferous wood pulp, hardwood pulp and tobacco raw materials are mixed and beaten, and the mixed beating degree is 42 o Sr. The ratio of substrate raw materials is as follows (dry basis): 14% wood pulp, 78% tobacco pulp, and 8% calcium carbonate. Wherein, the ratio of coniferous wood and hardwood in wood pulp is 1.5:1. Tobacco pulp, coniferous wood pulp and hardwood pulp are mixed and adjusted to a pulp concentration of 1.0%, and then divided into two parts, and the same flow is sent to the top head box and the bottom head box for papermaking. The weight of the substrate formed by the top net head box and the bottom net is set to 25g / m 2 .

[0043] (2) Preparation of powdered raw materials

[0044] Select dried konjac, mushrooms and cloves as functional solid materials, grind them to particle sizes of 260 microns, 200 microns and 300 microns with an ultrafine pulverize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com