Organic silicon pressure-sensitive adhesive without pause marks and with high anchoring property, preparation method and application thereof

A silicone pressure-sensitive adhesive and anchoring technology, which is applied in the direction of pressure-sensitive films/sheets, adhesives, polymer adhesive additives, etc., can solve the problem of inability to adjust the softness and hardness of the rubber surface and anchoring properties, and is not suitable for low-temperature platinum vulcanization systems. Increase customer cost and operating steps, etc., to achieve good peel force stability, improved cohesive strength, and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

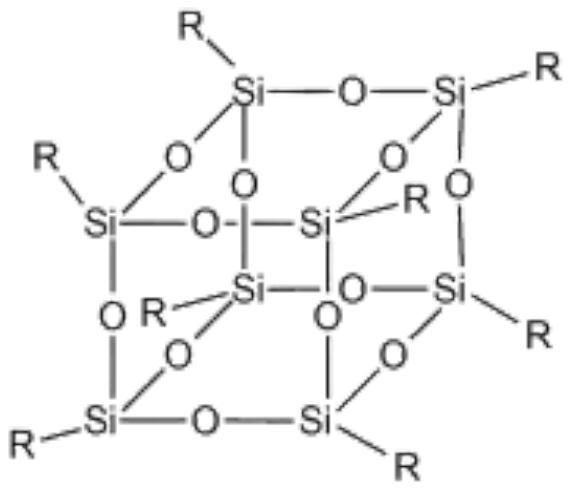

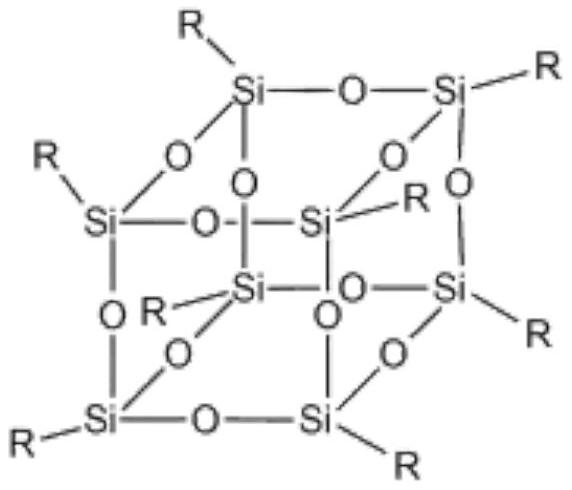

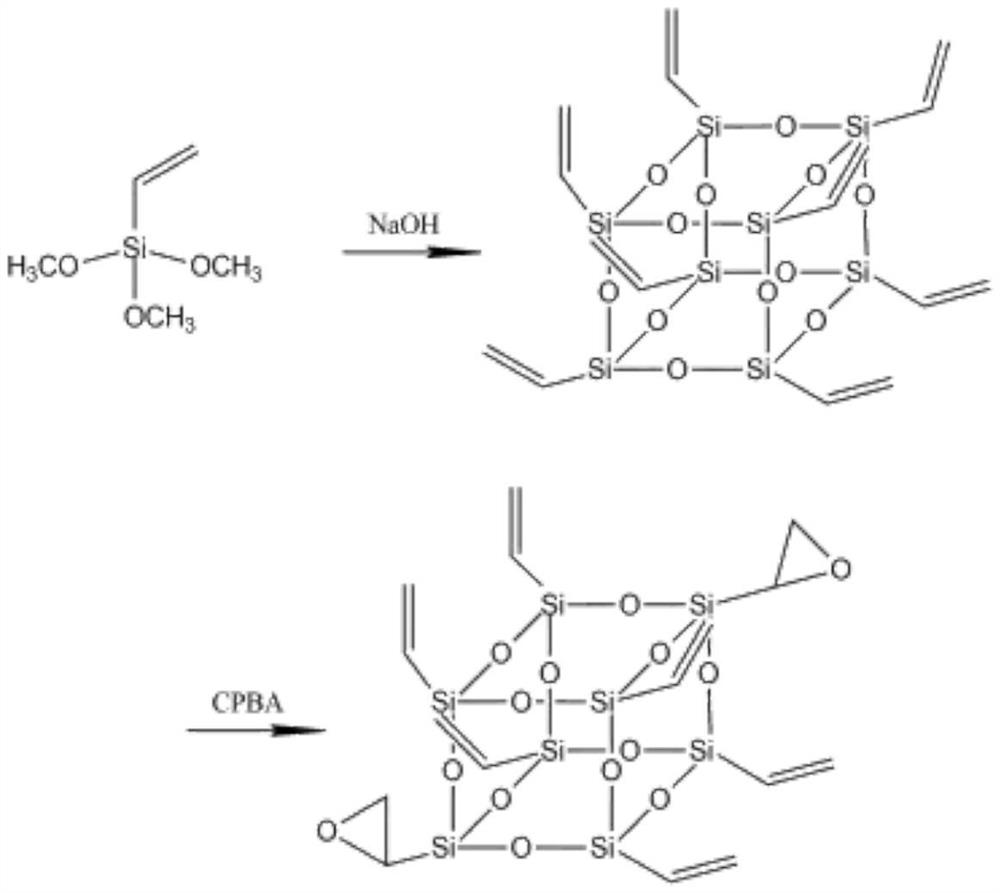

[0054] POSS: dioxirane hexavinyl cage polysilsesquioxane;

[0055] Methyl vinyl silicone rubber raw rubber: molecular weight 600,000, vinyl mass fraction 0.5%;

[0056] Vinyl MQ silicone resin: the M / Q ratio is 0.7, the mass fraction of vinyl is 1.5%, and the molar mass is 4400g / mol;

[0057] Hydroxy raw rubber: molecular weight 600,000;

[0058] Hydroxy MQ silicone resin: M / Q ratio is 0.7, molar mass is 3000g / mol;

[0059] Silicon-hydrogen crosslinking agent: the viscosity is 100 mPa.s, and the mass fraction of terminal hydrogen groups and side hydrogen groups is 1.6%.

[0060] 1) Add 20g methyl vinyl silicone rubber raw rubber, 10g vinyl MQ silicone resin, 10g hydroxyl raw rubber, 10g hydroxyl MQ silicone resin and 20g toluene, 0.4g POSS, 0.1g ethynyl cyclohexanol inhibitor into the reactor , stir to dissolve;

[0061] 2) Stir with nitrogen gas, after stirring evenly, dilute 0.18g of acetic acid with 20g of toluene and add slowly, then react under reflux dehydration at 1...

Embodiment 2

[0065] POSS: epoxyethyl heptavinyl cage polysilsesquioxane;

[0066] Methyl vinyl silicone rubber raw rubber: molecular weight 700,000, vinyl mass fraction 0.1%;

[0067] Vinyl MQ silicone resin: the M / Q ratio is 0.7, the mass fraction of vinyl is 0.5%, and the molar mass is 4800g / mol;

[0068] Hydroxy raw rubber: molecular weight 700,000;

[0069] Hydroxyl MQ silicone resin: M / Q ratio is 0.7, molar mass is 5000g / mol;

[0070] Silicon-hydrogen crosslinking agent: the viscosity is 100 mPa.s, and the mass fraction of terminal hydrogen groups and side hydrogen groups is 1.0%.

[0071] 1) Inhibit 20g of methyl vinyl silicone rubber, 25g of vinyl MQ silicone resin, 2g of hydroxyl raw rubber, 10g of hydroxyl MQ silicone resin, 20g of toluene, 0.2g of POSS, and 0.3g of divinyltetramethyldisiloxane The agent is added to the reaction kettle, stirred and dissolved;

[0072] 2) Stir with nitrogen gas, after stirring evenly, dilute 0.15g of benzoic acid with 32g of toluene and add slo...

Embodiment 3

[0076] POSS: dioxirane hexavinyl cage polysilsesquioxane;

[0077] Methyl vinyl silicone rubber raw rubber: molecular weight 600,000, vinyl mass fraction 0.4%;

[0078] Vinyl MQ silicone resin: the M / Q ratio is 0.7, the mass fraction of vinyl is 1.8%, and the molar mass is 4000g / mol;

[0079] Hydroxy raw rubber: molecular weight 600,000;

[0080] Hydroxy MQ silicone resin: M / Q ratio is 0.7, molar mass is 3000g / mol;

[0081] Silicon-hydrogen crosslinking agent: the viscosity is 80 mPa.s, and the mass fraction of terminal hydrogen groups and side hydrogen groups is 0.8%.

[0082] 1) Add 20g methyl vinyl silicone rubber raw rubber, 12g hydroxyl raw rubber, 10g hydroxyl MQ silicone resin, 10g vinyl MQ silicone resin and 20.5g toluene, 0.4g POSS, 0.1g ethynyl cyclohexanol inhibitor into the reactor , stir to dissolve;

[0083] 2) Stir with nitrogen gas, after stirring evenly, dilute 0.2g of propionic acid with 20g of toluene and add slowly, then react at 150°C for 5h under refl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com