Preparation method of wet curing reaction-type polyurethane hot melt adhesive for textile

A polyurethane hot-melt adhesive, moisture-curing technology, used in textiles and papermaking, polyurea/polyurethane adhesives, adhesives, etc., can solve the problems of poor hydrolysis resistance, poor flexibility, low initial and final adhesive strengths, etc. To achieve the effect of good hydrolysis resistance, good water resistance, good initial tack and final tack strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

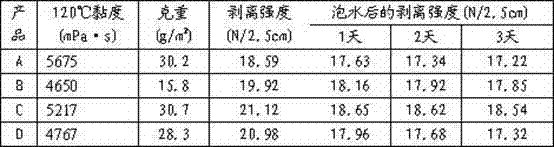

Examples

Embodiment 1

[0021] (1) Put 51g of polyether polyol 4000E, 8g of polyester polyol 3000H, 8g of ester polyol 2000N, 0.22g of antioxidant 1010 and 0.22g of antioxidant 1076 into a three-necked flask, stir and mix and heat up to 120 At about ℃, dehydration for 0.5h under vacuum less than 100Pa;

[0022] (2) Add 20g of tackifying resin into the above flask, continue to heat up to 135-140°C, and dehydrate for 1.5h at a vacuum degree of less than 100Pa;

[0023] (3) Cool down to 87°C, add 12g MDI, 0.07 stannous octoate and 0.07g DMDEE, stir, and react for 2 hours at 85-95°C, vacuum degree less than 100Pa;

[0024] (4) Release the vacuum, add 0.5g of white carbon black, stir quickly, mix well, and continue to stir for 10min under a vacuum degree of less than 100Pa;

[0025] (5) Keep the discharge temperature at 85-100°C, discharge quickly, seal in an aluminum foil bag under nitrogen protection, and mature in an oven at 80-85°C for 4 hours to obtain product A.

Embodiment 2

[0027] (1) Put 46g of polyether polyol 4000E, 10g of polyester polyol 3000H, 10g of ester polyol 2000N, 0.22g of antioxidant 1010 and 0.22g of antioxidant 1076 into a three-necked flask, stir and mix and heat up to 120 At about ℃, dehydration for 0.5h under vacuum less than 100Pa;

[0028] (2) Add 19g of tackifying resin into the above flask, continue to heat up to 135-140°C, and dehydrate for 1.5h at a vacuum degree of less than 100Pa;

[0029] (3) Cool down to 87°C, add 12g MDI, 0.07 stannous octoate and 0.07g DMDEE, stir, and react for 2 hours at 85-95°C, vacuum degree less than 100Pa;

[0030] (4) Release the vacuum, add 0.5g of white carbon black, stir quickly, mix well, and continue to stir for 10min under a vacuum degree of less than 100Pa;

[0031] (5) Keep the discharge temperature at 85-100°C, quickly discharge, seal in an aluminum foil bag under nitrogen protection, and mature in an oven at 80-85°C for 4 hours to obtain product B.

Embodiment 3

[0033] (1) Put 44g of polyether polyol 4000E, 11g of polyester polyol 3000H, 11g of ester polyol 2000N, 0.22g of antioxidant 1010 and 0.22g of antioxidant 1076 into a three-necked flask, stir and mix and heat up to 120 At about ℃, dehydration for 0.5h under vacuum less than 100Pa;

[0034] (2) Add 19g of tackifying resin into the above flask, continue to heat up to 135-140°C, and dehydrate for 1.5h at a vacuum degree of less than 100Pa;

[0035] (3) Cool down to 87°C, add 11g MDI, 0.07 stannous octoate and 0.07g DMDEE, stir, and react for 2 hours at 85-95°C, vacuum degree less than 100Pa;

[0036] (4) Release the vacuum, add 0.5g of white carbon black, stir quickly, mix well, and continue to stir for 10min under a vacuum degree of less than 100Pa;

[0037] (5) Keep the discharge temperature at 85-100°C, discharge quickly, seal in an aluminum foil bag under nitrogen protection, and mature in an oven at 80-85°C for 4 hours to obtain product C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com