Ultrahigh molecular weight polyethylene UD non-woven fabric and photocuring preparation method

An ultra-high molecular weight, non-weft fabric technology, applied in the textile field, can solve the problems of loose fiber adhesion, poor elongation resistance, and low production efficiency, and achieve the effects of reducing the depth of the depression, improving the anti-ballistic performance, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

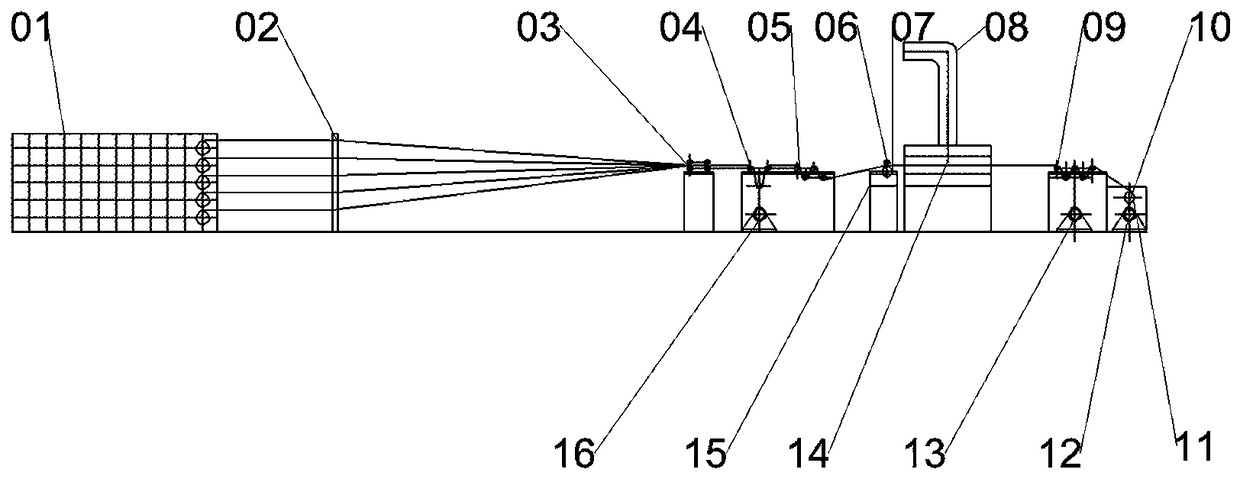

[0029] like figure 1 As shown, the present embodiment provides a continuous production line for light curing of ultra-high molecular weight polyethylene UD non-weft cloth, including: a pay-off frame 1 arranged at the front end, with 1000 shafts installed in total; behind the pay-off frame There is a thread distribution frame 2 at the end, which is equipped with 1000 ceramic rings, and the fibers are evenly distributed in a width of 1600mm; 4 tension rollers 3 are arranged behind the thread branch frame, and the tension can be adjusted pneumatically; the tension The front traction roller 4 is arranged behind the roller, and is driven by the front traction motor 16 of frequency conversion speed regulation; a group of laying rollers 5 are arranged afterwards, and the ultra-high molecular weight polyethylene fibers are evenly and tightly distributed on the laying rollers; resin tanks 15 are arranged thereafter, The resin tank is equipped with a heating belt and a temperature contr...

Embodiment 2

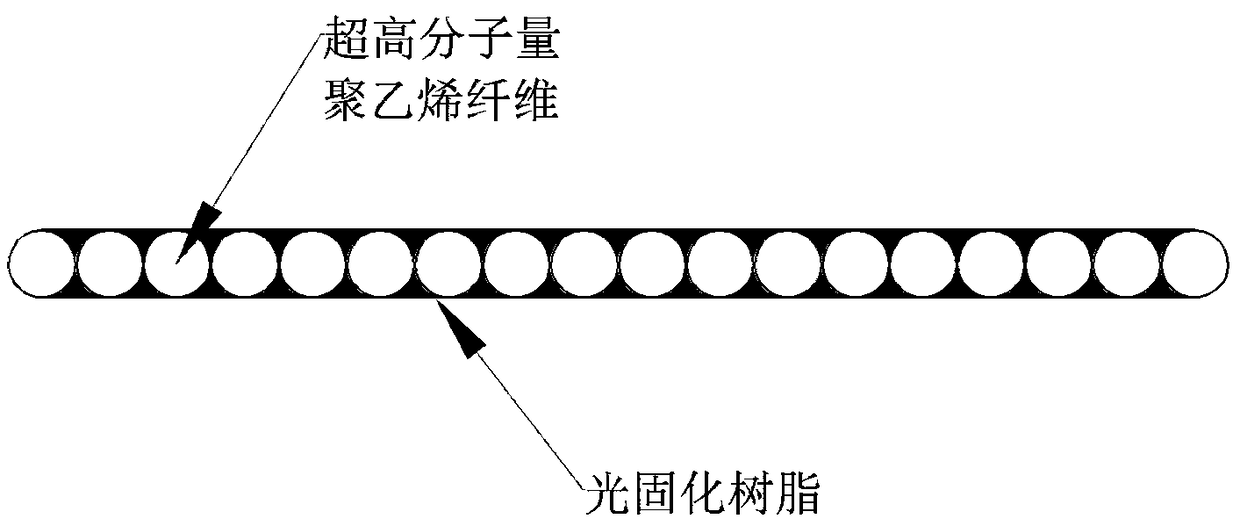

[0031] This example provides an ultra-high molecular weight polyethylene UD non-weft fabric with a width of 1600mm, which includes ultra-high molecular weight polyethylene fibers and photocurable resin filled between the fibers, and is made by rapid curing through a photocuring process. The specific preparation method as follows:

[0032] (1) Mixing of photoinitiation system and resin system

[0033] Mix and disperse the photoinitiator system, photocurable prepolymer and active monomer evenly, and dissolve the photoinitiator system in the prepolymer and active monomer to form a uniform photocurable resin, which is filled into the resin tank;

[0034] Wherein the weight fraction ratio of each component of photoinitiating system, photocuring prepolymer and active monomer is:

[0035] Prepolymer: 80 parts of unsaturated polyester, 20 parts of epoxy resin;

[0036] Active monomer: 40 parts of styrene, 10 parts of pentaerythritol triacrylate;

[0037] Photoinitiation system: ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com