Manufacture method of steamed oat grains

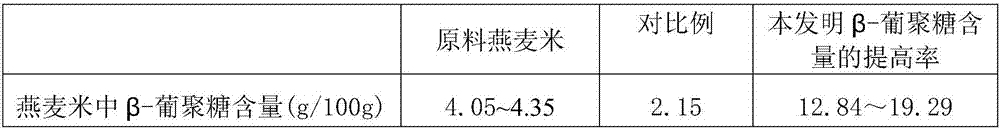

A production method and parboiled rice technology are used in food ingredients as taste improvers, food science and other directions, can solve the problems of astringent taste, hard texture of oat grains, inconvenience in eating, etc., and improve the degree of gelatinization and nutrition. Value, effect of good sensory quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Cleaning: Take 1kg of oat grains and use an air sieve cleaning machine to remove large miscellaneous sandy soil, grass stems, etc. → use a horizontal wheat thresher to remove wheat hair → use a circular sorter to remove light miscellaneous wheat husks → use a roller classifier to remove Thin and small grains→Use the rice and rough separator to remove the skin grains→Use the socket selection machine to remove tartary buckwheat, grass seeds, etc.→Use the gravity cleaning machine to remove half grains and unfulfilled grains→Use the color sorter to remove black grains and discolored grains .

[0035] (2) One-time soaking: the cleaned oat grains are soaked in a mixed aqueous solution of 5wt% citric acid, 0.75wt% calcium hydrogen phosphate, and 0.075wt% calcium dihydrogen phosphate with a concentration of oat grains 2 times the mass; when soaking, stir the oatmeal evenly so that the oatmeal is dispersed and not agglomerated. The soaking temperature is 45°C, and the soaki...

Embodiment 2

[0043] (1) Cleaning: Take 1kg of oat grains and use an air sieve cleaning machine to remove large miscellaneous sandy soil, grass stems, etc. → use a horizontal wheat thresher to remove wheat hair → use a circular sorter to remove light miscellaneous wheat husks → use a roller classifier to remove Thin and small grains→Use the rice and rough separator to remove the skin grains→Use the socket selection machine to remove tartary buckwheat, grass seeds, etc.→Use the gravity cleaning machine to remove half grains and unfulfilled grains→Use the color sorter to remove black grains and discolored grains .

[0044] (2) Soak once: the cleaned oat grains will be soaked in a mixed aqueous solution of 8wt% citric acid, 1wt% calcium hydrogen phosphate, and 0.1wt% calcium dihydrogen phosphate with a concentration, and the quality of the soaking solution is the quality of oat grains 3 times; when soaking, stir the oatmeal evenly so that the oatmeal is dispersed and not agglomerated. The soa...

Embodiment 3

[0052] (1) Cleaning: Take 1kg of oat grains and use an air sieve cleaning machine to remove large miscellaneous sandy soil, grass stems, etc. → use a horizontal wheat thresher to remove wheat hair → use a circular sorter to remove light miscellaneous wheat husks → use a roller classifier to remove Thin and small grains→Use the rice and rough separator to remove the skin grains→Use the socket selection machine to remove tartary buckwheat, grass seeds, etc.→Use the gravity cleaning machine to remove half grains and unfulfilled grains→Use the color sorter to remove black grains and discolored grains .

[0053] (2) One-time soaking: soak the cleaned oat grain with a mixed aqueous solution of 3wt% citric acid, 0.5wt% calcium hydrogen phosphate, and 0.05wt% calcium dihydrogen phosphate, and the quality of the soaking solution is oat grain 2.5 times the mass; when soaking, stir the oatmeal evenly so that the oatmeal is dispersed and not agglomerated. The soaking temperature is 30°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com