Patents

Literature

185 results about "Monobasic calcium phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium Phosphate Monobasic is mainly used in fertilizers, as acidulant in baking powders and in wheat flours, mineral supplement for foods and feeds, in enameling.

Antibiotic-free piglet conservation material and preparation method thereof

InactiveCN102987153AComprehensive and balanced nutritionIncrease production capacityAnimal feeding stuffPhytaseThreonine

The invention relates to an antibiotic-free piglet conservation material and a preparation method thereof. The conservation material comprises the following raw materials of puffed corn, wheat, a base material, efficient cream, soybean meal, fermentation soybean meal, whey powder, composite yeast, rice protein powder, stone powder, calcium hydrogen phosphate, lysine, methionine, threonine, choline chloride, liquid phytase, liquid xylanase, a acidifying agent, sodium butyrate and a premix compound. The antibiotic-free piglet conservation material can increase immunity of the piglet, prevents the piglet from generating drug resistance and appearing drug residue problems, maintains stability of intestinal flora, and improves digestion and absorption for forage of the piglet.

Owner:河南商都生物技术股份有限公司

Distillers dried grains with soluble (DDGS)-containing meat duck feed and preparation method thereof

InactiveCN102178116AMeet the nutritional needs of growthReduce dosageFood processingAnimal feeding stuffPhytaseBetaine

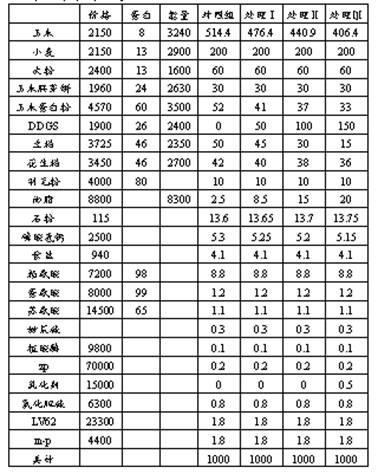

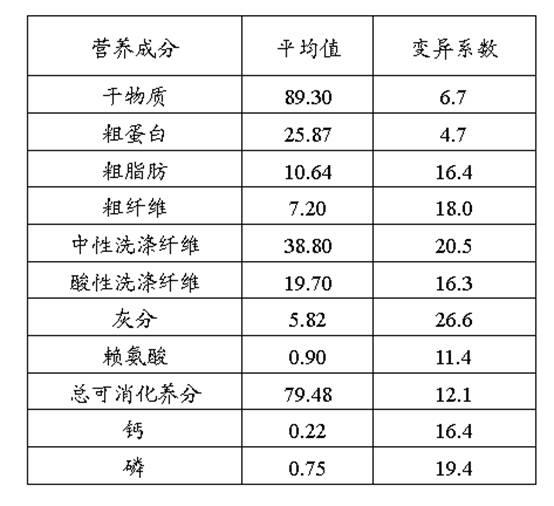

The invention discloses DDGS-containing meat duck feed and a preparation method thereof. The compound feed comprises the following raw materials: corn, wheat, wheat middling, maize embryo cake, corn gluten meal, DDGS, bean pulp, peanut pulp, feather meal, fat, table salt, stone powder, calcium hydrophosphate, choline chloride, methionine, threonine, lysine, betaine, phytase, composite premix, emulsifier, vitamin premix and trace element premix. The preparation method comprises the following steps: weighing, crushing, mixing, granulating and crushing. When the technical scheme provided by the invention is adopted, the feed and the preparation method have the advantages that: the mixing ratio is scientific; the manufacturing is simple; and the DDGS high-quality raw material is used, the consumption of conventional protein raw materials such as corn and soybean pulp is reduced, the cost of the feed is reduced, the nutrient demands of meat ducts for growth are satisfied, adverse effect onthe growth property of the meat ducts is avoided, muscle rate is improved, abdominal fat rate is lowered, the quality of meat is improved obviously, and the crop rate is high.

Owner:SHANDONG NEW HOPE LIUHE GROUP

Non-resistant dust-free piglet creep formula feed and preparation method thereof

PendingCN107927384ACollocation scienceImprove digestion and absorption rateAnimal feeding stuffAccessory food factorsPhytaseSucrose

The invention discloses non-resistant dust-free piglet creep formula feed and a preparation method thereof. The feed is prepared from the following components: corns, fermented corns, soybean meal, fermented soybean meal, expanded soybean flour, expanded corn flour, imported fish meal, spray-dried plasma proteins, dried porcine solubles, powdered whey, soybean oil, sucrose, molasses, sodium glutamate, a feeding promoting agent, Yibao phospholipid, yeast autolysate, an acidifying agent, stone powder, calcium hydrogen phosphate, table salt, 98.5 percent of lysine, 98.5 percent of threonine, 10 percent of tryptophan, special compound enzyme for early-weaned piglets, phytase enzyme, a micro-ecological preparation, a Chinese herbal medicine heath preserver, antibacterial peptide, immunopotentiator, 50 percent of choline chloride and a premix. The preparation method comprises the following steps: firstly, separately preparing granulated feed products and powdery feed products; and then mixing the granulated feed products with the powdery feed products to obtain the non-resistant dust-free piglet creep formula feed. According to the feed disclosed by the invention, antibiotics are not added, a formula is scientific, the dust of the product is low, the palatability and the immunity are improved, and a diarrhea ratio of piglets is reduced.

Owner:江苏中煤长江生物科技有限公司

Antibiotic-free feed for nursery pigs and preparation method thereof

InactiveCN106889328AIncrease production capacityImprove disease resistanceFood processingAnimal feeding stuffBiotechnologyPhytase

The invention discloses an antibiotic-free feed for nursery pigs and a preparation method thereof. Corn, barley and soybean meal are pre-cleaned to remove impurities and enter a permanent magnet drum to remove tramp iron; the materials enter a bin for smashing respectively; smashing is performed, 100% of smashed materials are subjected to 14-mesh sieving, and 95% of the smashed materials are subjected to 20-mesh sieving; suckling pig compound enzyme, a vitamin premixing agent, a microbial ecological agent, plant essential oil, phagostimulant, high temperature resistant phytase, an organic microelement premixing agent, a Chinese herbal medicine prescription, yeast cell wall polysaccharide, glycerol monobutyralte and an emulsifier are firstly mixed fully for use; then the corn, the barley, the soybean meal, soybean oil, extruded soybeans, fermented soybean meal, import fish meal, whey mist, salt, calcium formate, calcium hydrophosphate, amino acid, composite organic acid, an antioxidant and a mildewproof agent are weighed in proportion and then are compounded and mixed; finally granulation is performed. An antibiosis growth promotion effect which is the same as or better than that obtained by using antibiotics can be achieved, the sensibility of germs to the antibiotics is improved, and the treatment drug effect is improved.

Owner:HUNAN JIUDING TECH GROUP

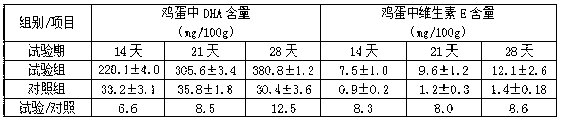

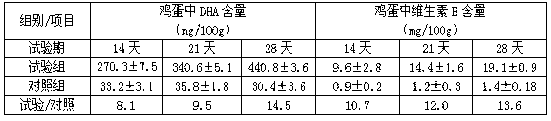

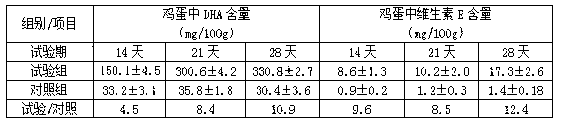

Production method for eggs rich in DHA and Vitamin E ingredients

The invention discloses a production method for eggs rich in DHA and Vitamin E ingredients. The production method has the advantages that the health of laying hens is not affected and the quality guarantee period of products is prolonged. The production method comprises the following steps of: a. in the period that the laying hens lay eggs, feeding the laying hens with a feed adopting the following formula in mass ratios: 500-650 of corn, 200-240 of bean pulp, 15-20 of corn protein powder for the feed, 20-30 of rice bran meal, 20-50 of corn DDGS (distillers dried grains with soluble), 20-30 of wheat bran, 65-70 of limestone powder, 5-15 of calcium hydrophosphate, 15-100 of fish oil, 30-100 of flaxseed, 2-4 of edible salt, 0.8-1 of methionine, 0.3-0.5 of vitamin premix feed, 0.1-0.5 of adsorption type vitamin E powder, 1-1.5 of trace element, 1-2 of choline chloride, 0.5-1 of probiotics Bio-Aid, 0.25-0.5 of Kewei enzyme, 0.1-0.2 of phytase and 0.2-0.4 of composite betain; and b. three weeks later, collecting the eggs laid by the laying eggs.

Owner:DALIAN HANWEI CHICKEN FARM

A compound feed for improving meat quality of cultured Litopenaeus. vannamei

ActiveCN1875746AIncrease elasticityImprove meat qualityFood processingClimate change adaptationBiotechnologyChemical synthesis

Disclosed is a mixed feed for improving prawn quality, wherein the mixed feed is prepared from the following raw materials (by weight ratio): fish meal 25-33%, soya bean waste 18-22%, maize protein meal 8-10%, refined flour 20-25%, brewers' yeast 3-5%, selenium-rich yeast 2-3%, squid grease 3-4%, sea-tangle powder 2-3%, monobasic calcium phosphate 0.8-1%, fish oil 0.8-1.2%, vitamin premixed material 1-2%, mineral premixed material 1-2%, astaxanthin 0.2-0.5g, carnitine 0.2-0.3g, Saccharicter-penin 50-70mg, soybean isoflavones 20-30mg, VC 1-2g, and choline chloride 1-2g.

Owner:GUANGDONG EVERGREEN FEED INDAL

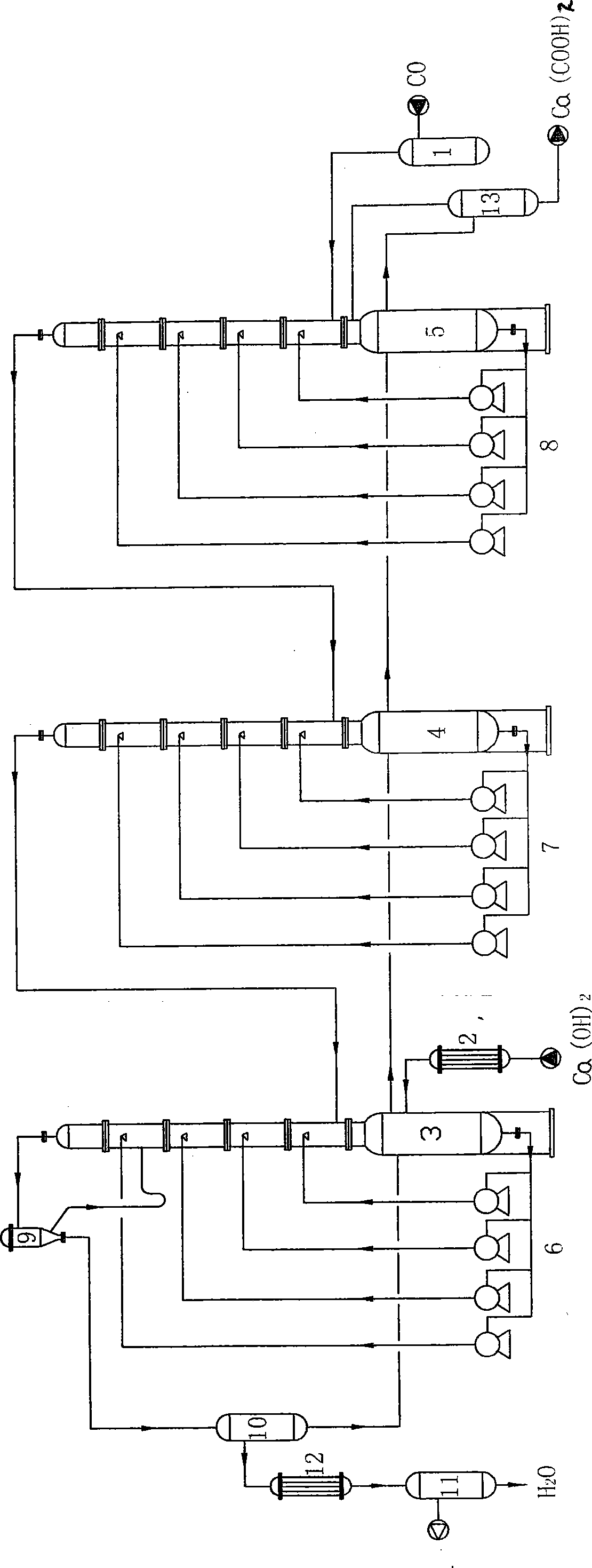

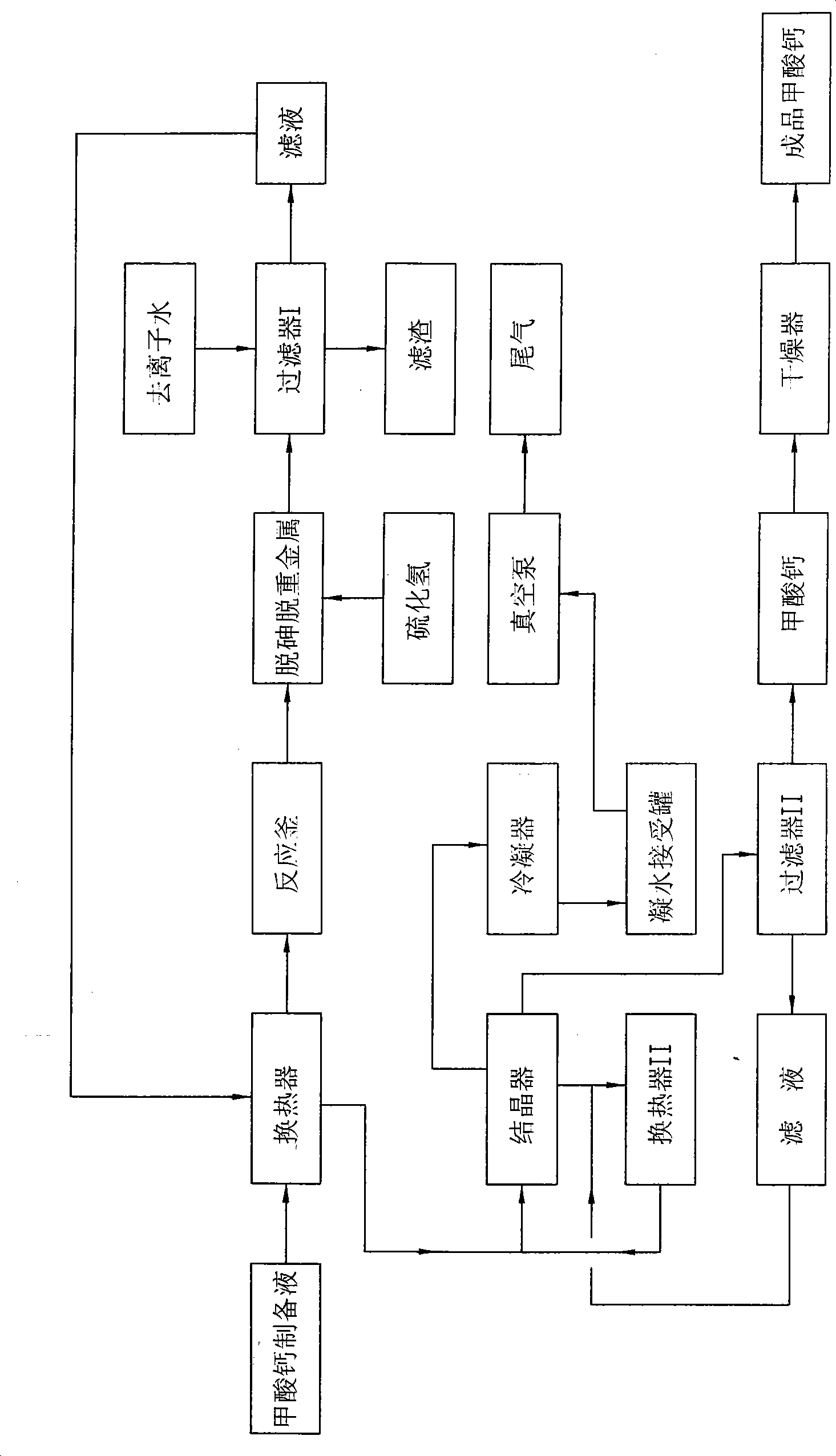

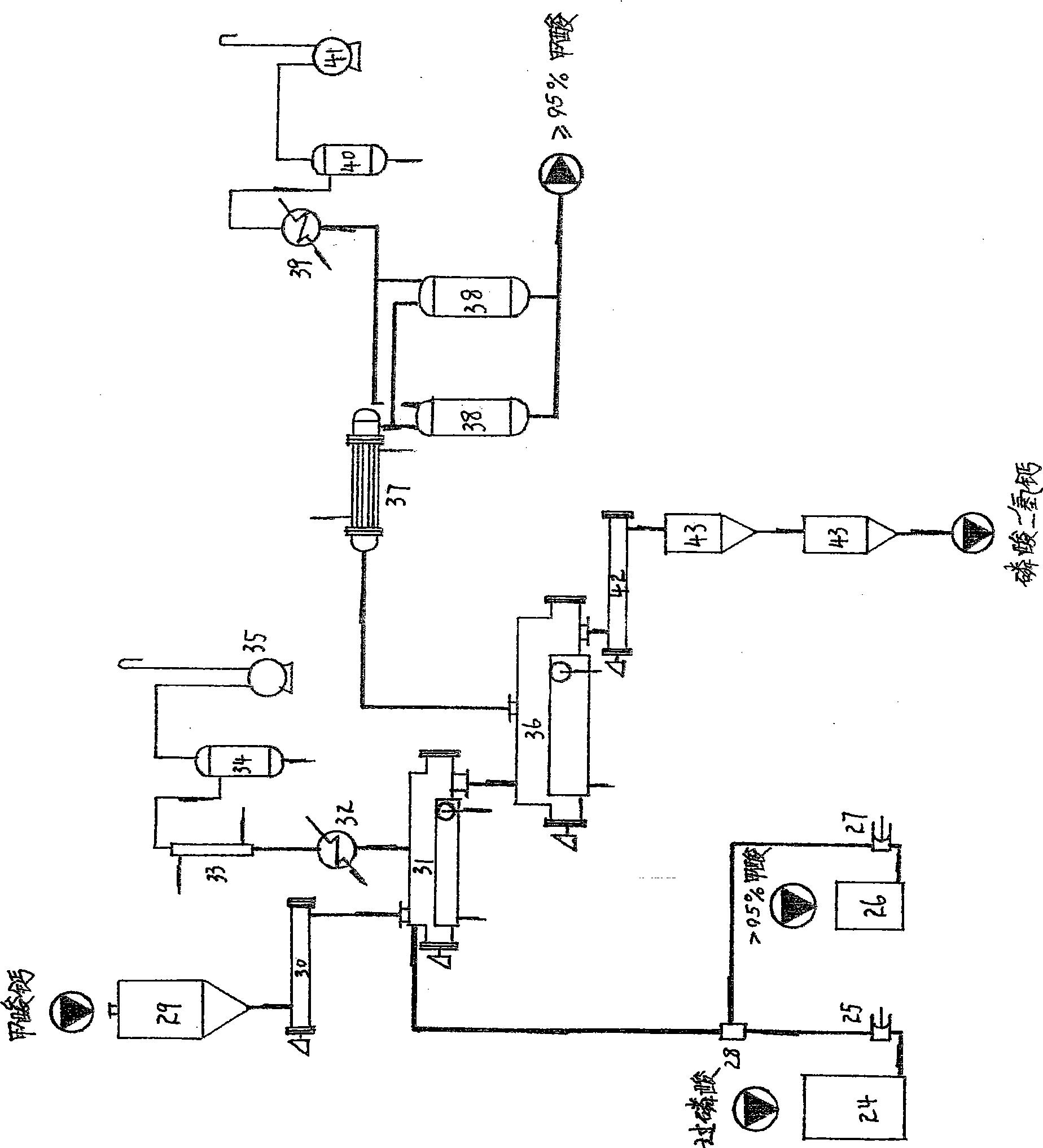

Method for coproduction of high purity aminic acid and acid sodium phosphate by reaction of calcium formate and peroxyphosphoric acid

InactiveCN101475463ASimple production processReduce manufacturing costPreparation from carboxylic acid saltsPhosphorus compoundsCalcium hydroxideHydrogen

The invention relates to a method for coproducing high-purity methanoic acid and monobasic sodium phosphate by reaction of calcium formate and ultraphosphate. The method comprises the following steps that: carbon monoxide enters a reaction tower III; calcium hydroxide enters a reaction tower I to perform a counterflow reaction with carbon monoxide from a reaction tower II, a reaction solution overflows to the reaction tower II to perform the counterflow reaction with the carbon monoxide from the reaction tower III, the reaction solution enters the reaction tower III to perform the couterflow reaction with the carbon monoxide, the reaction solution overflows into a discharge tank from the reaction tower III to prepare a calcium formate preparation solution; the calcium formate preparation solution enters a reaction kettle, methanoic acid is dripped into the reaction kettle, sulfureted hydrogen is introduced into the reaction kettle, the mixture is separated and filtered through a filter I, a filtrate enters a continuous crystallizer, a crystalline liquid enters a filter II, and the filtered calcium formate is prepared into a finished product calcium formate through a drier; ultraphosphate, the methanoic acid and the calcium formate are conveyed into a horizontal double screw reactor to generate the methanoic acid and monobasic calcium phosphate; the methanoic acid and the monobasic calcium phosphate enter a methanoic acid distilling still for reduced pressure distillation; and the monobasic calcium phosphate is delivered to a monobasic calcium phosphate measurement receiving tank, while the monobasic acid enters a methanoic acid receiving tank. The method has high yield of the methanoic acid and low manufacturing cost.

Owner:曹勇

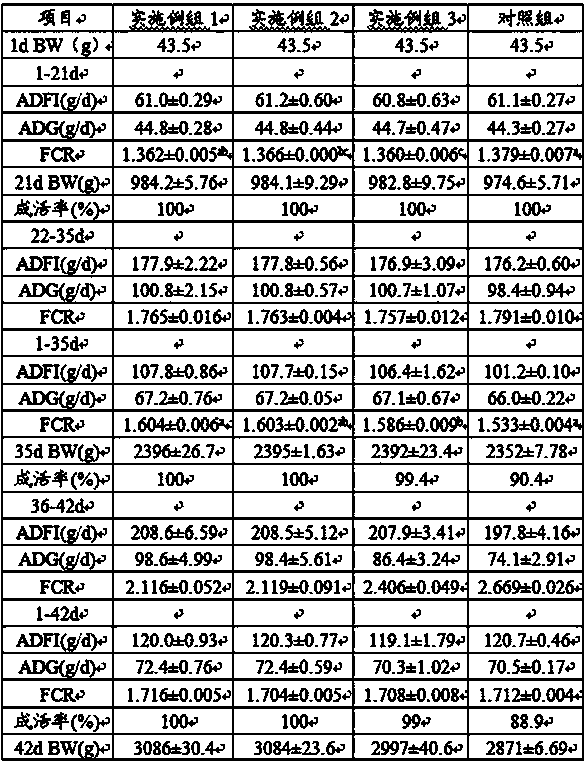

Compound feed for broilers at age between 1 day and 42 days and preparation method thereof

ActiveCN103392936AImprove feed conversionImprove slaughter performanceFood processingAnimal feeding stuffPhytaseThreonine

The invention discloses a compound feed for broilers at the age between 1 day and 42 days and a preparation method thereof. The compound feed comprises the following raw materials in parts by weight: corn, hard wheat, soya-bean oil, 46% soybean meal, peanut meal, distillers dried grains with soluble (DDGS), corn protein powder, stone powder, calcium hydrogen phosphate, salt, lysine sulfate, methionine, threonine, liquid phytase, choline chloride, a vitamin premix, a trace element mixture, a probiotic additive and a traditional Chinese medicine additive; the preparation method comprises the following steps: grinding, mixing, granulating and spraying. The beneficial effects of the compound feed are that: the compound feed is reasonable in the ratio of the raw materials, is simple to make, and is economical and affordable; and through adding of appropriate amounts of the probiotic additive and the traditional Chinese medicine additive, broiler feed conversion rate and slaughter performance can be significantly improved, and adverse effects of high temperature environment on broiler feed intake can be reduced.

Owner:唐山新希望六和饲料有限公司

Chicken feed additive for production of selenium and iodine enriched eggs and production method thereof

InactiveCN1965676AStable contentFull of nutritionAnimal feeding stuffAccessory food factorsVegetable oilManganese

The invention relates to a chicken forage formula which can improve selenium-iodine egg, and relative production, wherein it is formed by energy forage as corn and fat, protein forage as soybean cake, mineral forage as stone powder, calcium hydrogen phosphate, and common salt, nourishment forage additive as lycine, acimetion, vitamin, composite vitamin, and seaweed powder, and mineral microelement. And its production comprises that: a, mixing sodium selenate, potassium iodate and oligose; putting calcium hydrogen orthophosphate, seaweed powder, acimetion, lycine, vitamin, mineral microelement as copper, manganese, iron, and zinc, into ceramic pot to be mixed uniformly; b, breaking vegetable oil and corn; c, putting, corn powder, soybean, calcium stone powder, and forage additive, input forage mixer to be mixed for 10-15min, to produce the egg chicken forage. Said egg can improve physical quality.

Owner:司建茨

Method for preparing monopotassium phosphate from fertilizer grade calcium hydrophosphate

The invention relates to a method for preparing monopotassium phosphate from fertilizer grade calcium hydrophosphate. The method comprises the following steps of: slowly adding the fertilizer grade calcium hydrophosphate used as a material into a reaction tank containing potassium hydrogen sulfate solution at 60-68 DEG C, controlling the reaction solid-to-liquid ratio at (1:3)-(1:5) and the reaction time at 6.5-8 hours; controlling the sulphur and phosphorus mass ratio of the potassium hydrogen sulfate to the calcium hydrophosphate in reaction to S to P being (1-1.2):(1-1.4); adjusting the pH value of the filtrate by use of 85% industrial phosphoric acid; generating byproduct calcium sulfate whisker by filtering after the reaction is finished, adjusting the pH value of the filtrate to 4.5-5.5, and preparing the monopotassium phosphate product of meeting the top-quality goods of the national industry standard from the filtrate by purifying, concentrating, crystallizing, dewatering and drying, and controlling the drying temperature at 80-100 DEG C. By adopting the method, the technological process of producing the monopotassium phosphate is simple in flow, low in production cost, free of the three wastes, and easy for realization of large-scale and industrial production.

Owner:WENGFU (GRP) CO LTD

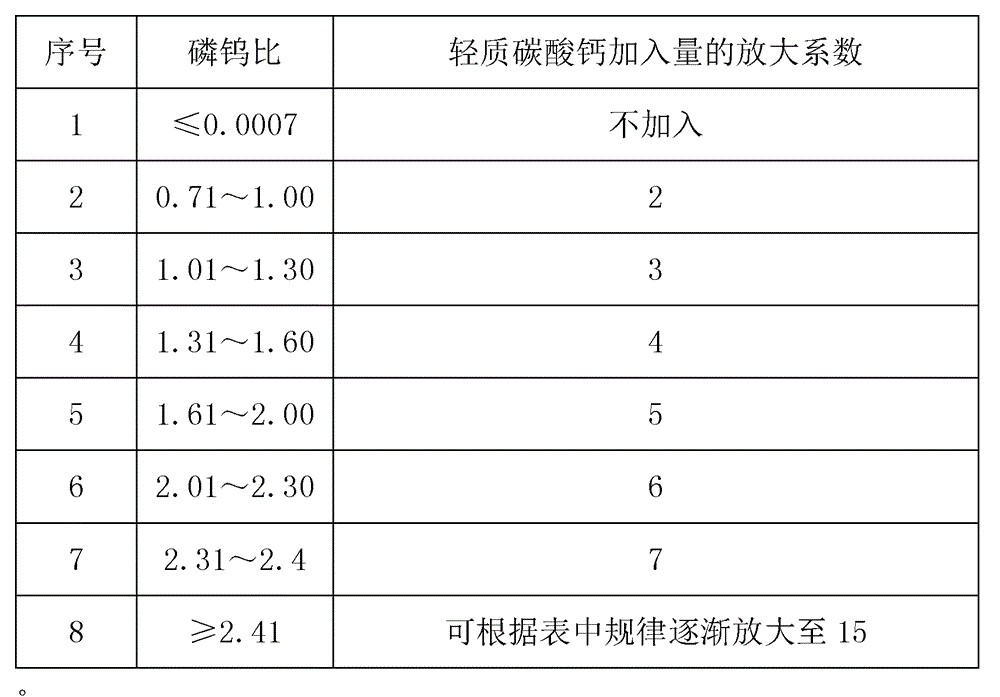

Method for deeply removing phosphorus in coarse sodium tungstate solution

The invention relates to a method for deeply removing phosphorus in a coarse sodium tungstate solution. The method is characterized in that in ammonium paratungstate production adopting an ion exchange method, a sample is taken from a coarse sodium tungstate solution obtained by reduced pressure decoction leaching, a detection result shows that a phosphorus-tungsten mass ratio of the sample is greater than or equal to 0.0007%, the material liquid is heated to a temperature of 90+ / -5 DEG C, light calcium carbonate is used as a phosphorus removal agent so that a reaction rate is fast and phosphorus removal efficiency is high, the phosphorus removal agent is added into the material liquid, wherein the use amount of the phosphorus removal agent is 2-15 times mass of phosphorus in the material liquid, the mixed solution undergoes a reaction for 30min under the conditions of thermal insulation and stirring so that phosphate groups in the phosphorus removal agent and the material liquid form difficultly soluble calcium hydrogen phosphate precipitates under the alkaline conditions, the reaction product liquid is filtered by a plate-and-frame filter press so that solid-liquid separation is realized and a novel solution with phosphorus content less than 0.06g / l and precipitates are obtained, and the novel solution subjected to phosphorus removal is used for production of ammonium paratungstate. Through the method, a phosphate mass concentration of the sodium tungstate solution is less than 0.5mg / l and a phosphorus removal rate is more than 99%.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP

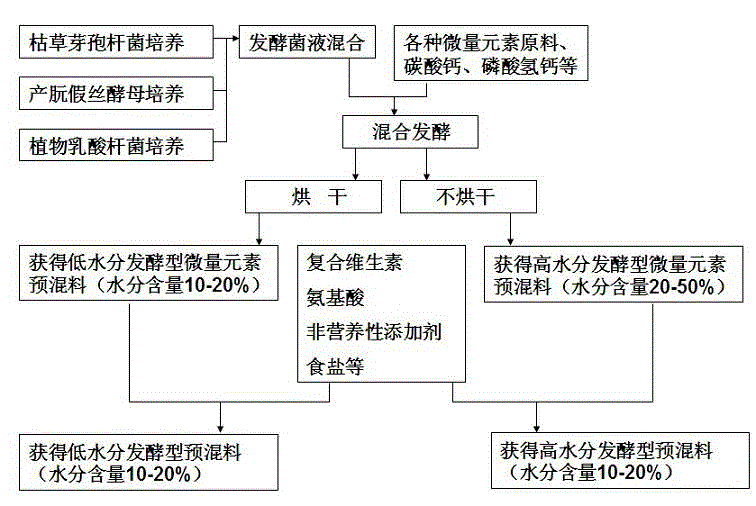

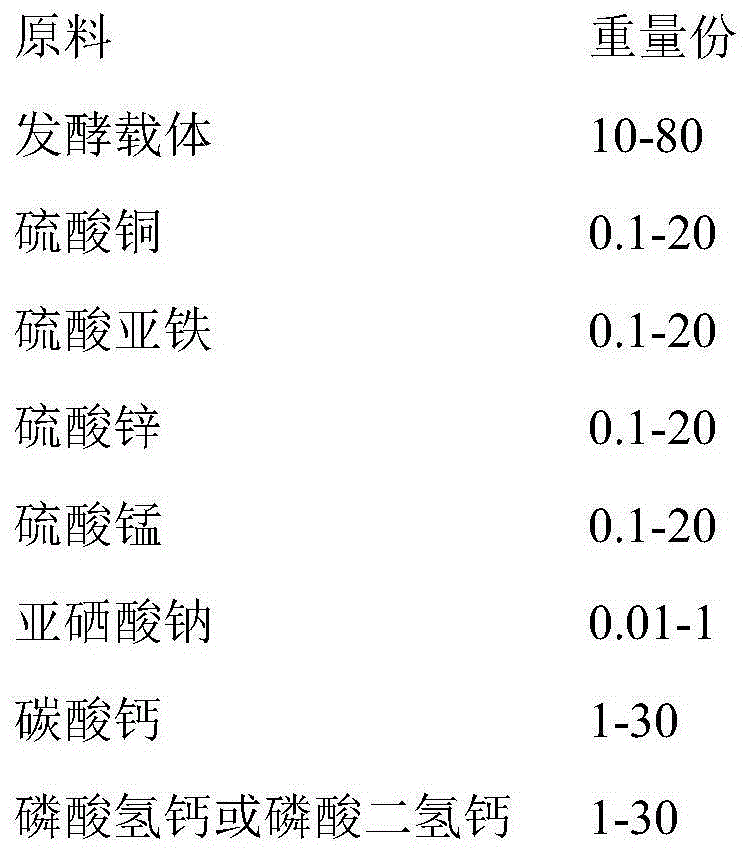

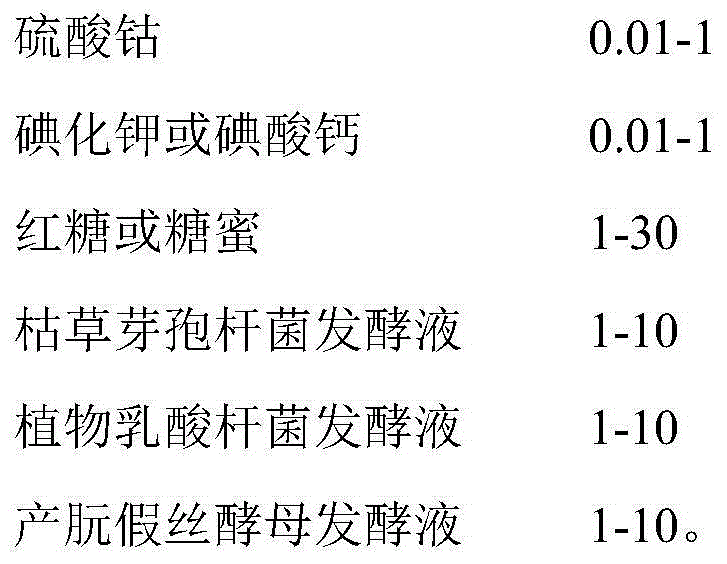

Fermentation trace element premix and preparation method thereof as well as fermentation composite premix and preparation method thereof

ActiveCN104798990AAdd lessImprove utilization efficiencyAnimal feeding stuffManganesePotassium iodine

The invention discloses a fermentation trace element premix and a preparation thereof as well as a fermentation composite premix and a preparation method thereof. The fermentation trace element premix comprises raw materials of bacillus subtilis, lactobacillus plantarum, candida utilis, a fermentation carrier, copper sulfate, ferrous sulfate, zinc sulfate, manganese sulfate, sodium selenite, calcium carbonate, calcium hydrophosphate, cobaltous sulfate and potassium iodide. The preparation method of the fermentation trace element premix comprises the following steps of uniformly mixing the raw materials according to a certain proportion; adjusting the water content; packaging the mixture with an airtight packaging bag; tightening a bag mouth and fermenting; drying or not drying a fermented product to obtain the fermentation trace element premix. The preparation method of the fermentation composite premix comprises the following steps of mixing the prepared fermentation trace element premix with vitamin, edible salts, an enzymic preparation, a non-nutritional additive, amino acid and the like according to the certain proportion, and packaging. According to the fermentation trace element premix and the fermentation composite premix, the formula is reasonable, the use is convenient, the animal feed intake is improved, the utilization rate of feed is improved, the animal diarrhea rate is reduced, the immunity and disease resistance of animals are improved, the environmental pollution is reduced, and the sustainable development of animal husbandry is promoted.

Owner:王升平

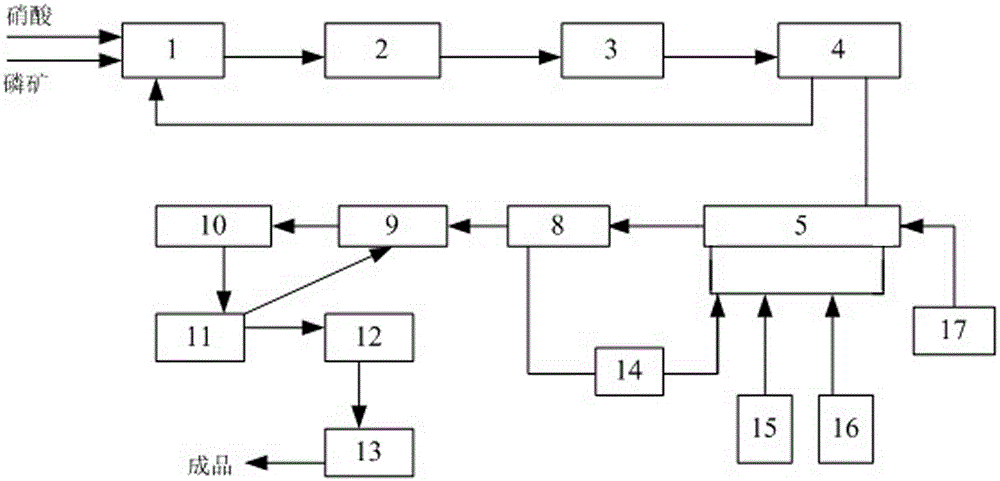

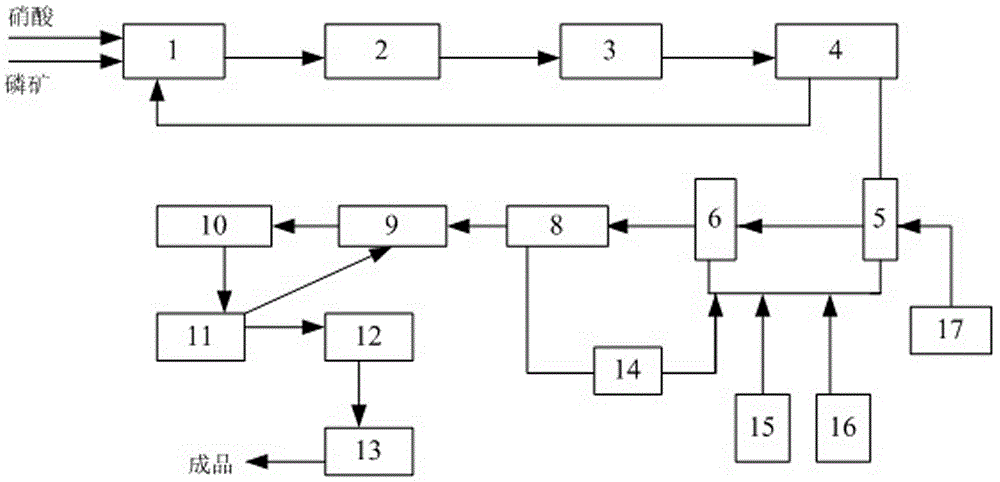

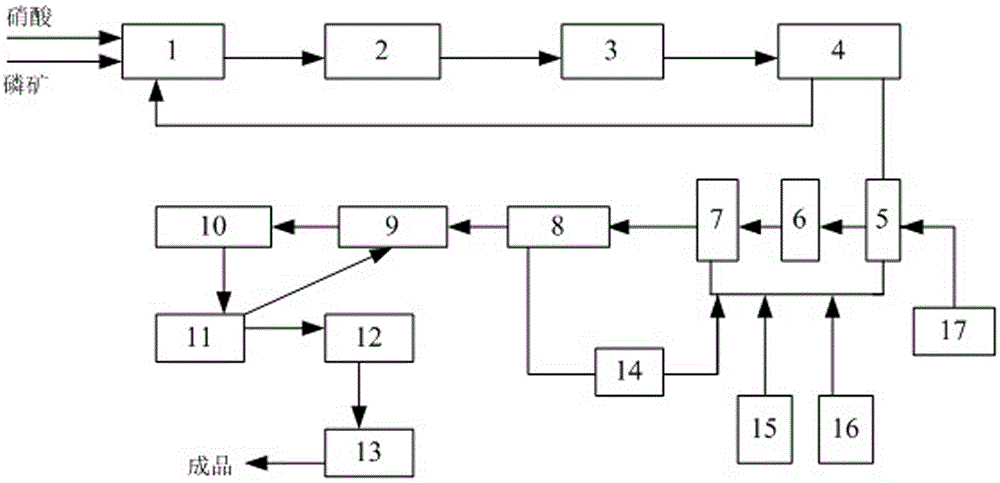

System and method for increasing nitric phosphate product P2O5 dissolvability in water

The invention discloses a system and a method for increasing a nitric phosphate product P2O5 dissolvability in water, belonging to the field of nitric phosphate production. Phosphorite is subjected to acidolysis, acid non-soluble substance separation, crystallization, filtering, neutralization, nitrogen and phosphorus evaporation, prilling, drying, screening, cooling and packing; mother liquor and potassium sulphate are added into a neutralizing tank according to a ratio, a small part of residual Ca<2+> are converted into calcium sulfate, generation of citric acid-soluble calcium hydrophosphate salt and insoluble phosphate is reduced, and K<+> is added in slurry. After the system is used, the production method is energy-saving and environment-friendly, a nutrient element kalium needed by plants is supplemented in a product while the dissolvability in water of a finished product P2O5 is increased, the material viscosity in a low temperature state in a neutralization process is reduced, and the quality of nitric phosphate is comprehensively improved.

Owner:TIANJI COAL CHEM IND GROUP

Poultry feed containing haematococcus pluvialis powder astaxanthin and preparation method

InactiveCN101940250ALow costIncrease costClimate change adaptationAnimal feeding stuffAnimal scienceHydrogen phosphate

The invention discloses poultry feed containing haematococcus pluvialis powder astaxanthin and a preparation method. The poultry feed comprises a main material and auxiliary materials, wherein the main material is flour and / or corn meal, and the auxiliary materials comprise bean pulp, calcium hydrogen phosphate and salt; the poultry feed also comprises haematococcus pluvialis powder; and the poultry feed contains 70 to 85 percent of main material, 10 to 25 percent of auxiliary materials and 5 to 10 percent of haematococcus pluvialis powder in percentage by weight, wherein the haematococcus pluvialis powder contains 0.05 to 0.5 percent of astaxanthin. A proper amount of haematococcus pluvialis powder is added in the poultry feed, the haematococcus pluvialis powder contains natural safe astaxanthin, and the astaxanthin content of the haematococcus pluvialis powder is proper, so after the poultry eat the feed, the poultry basically can lay red-core eggs with proper colors after 20 days, and the yield of the red-core eggs can reach over 99 percent; and the processing method is simple, the processing cost is low, and a raiser can process the feed by buying the haematococcus pluvialis powder with marked content.

Owner:NINGBO UNIV

Combination for promoting carapace growth and recovery of shrimp and crab of crustacean

InactiveCN101297817AHigh hardnessHigh glossOrganic active ingredientsInorganic phosphorous active ingredientsAnti stressDisease

The invention relates to a composition for promoting carapace growth and recovery of crustaceans of aquaculture animals, in particular to the composition for promoting the carapace growth and recovery of shrimps and crabs of the crustaceans. The composition is characterized in that: the composition by the parts by weight is as follows: 5 to 15 parts of vitamin D [3], 3 to 9 parts of vitamin C, 15 to 30 parts of monobasic calcium phosphate and 46 to 77 parts of carrier. The composition has the effects of promoting the growth and the recovery of the carapace and the hardness after carapace shedding of the shrimps and the crabs of the crustaceans, thus improving survival rate of carapace shedding, increasing bright color and luster of the surfaces of the shrimps and the crabs of the crustaceans, assisting treatment for carapace ulcer, improving the anti-disease ability and the anti-stress ability, increasing the carapace hardness and improving the yield.

Owner:TIANJIN SHENGJI GRP CO LTD

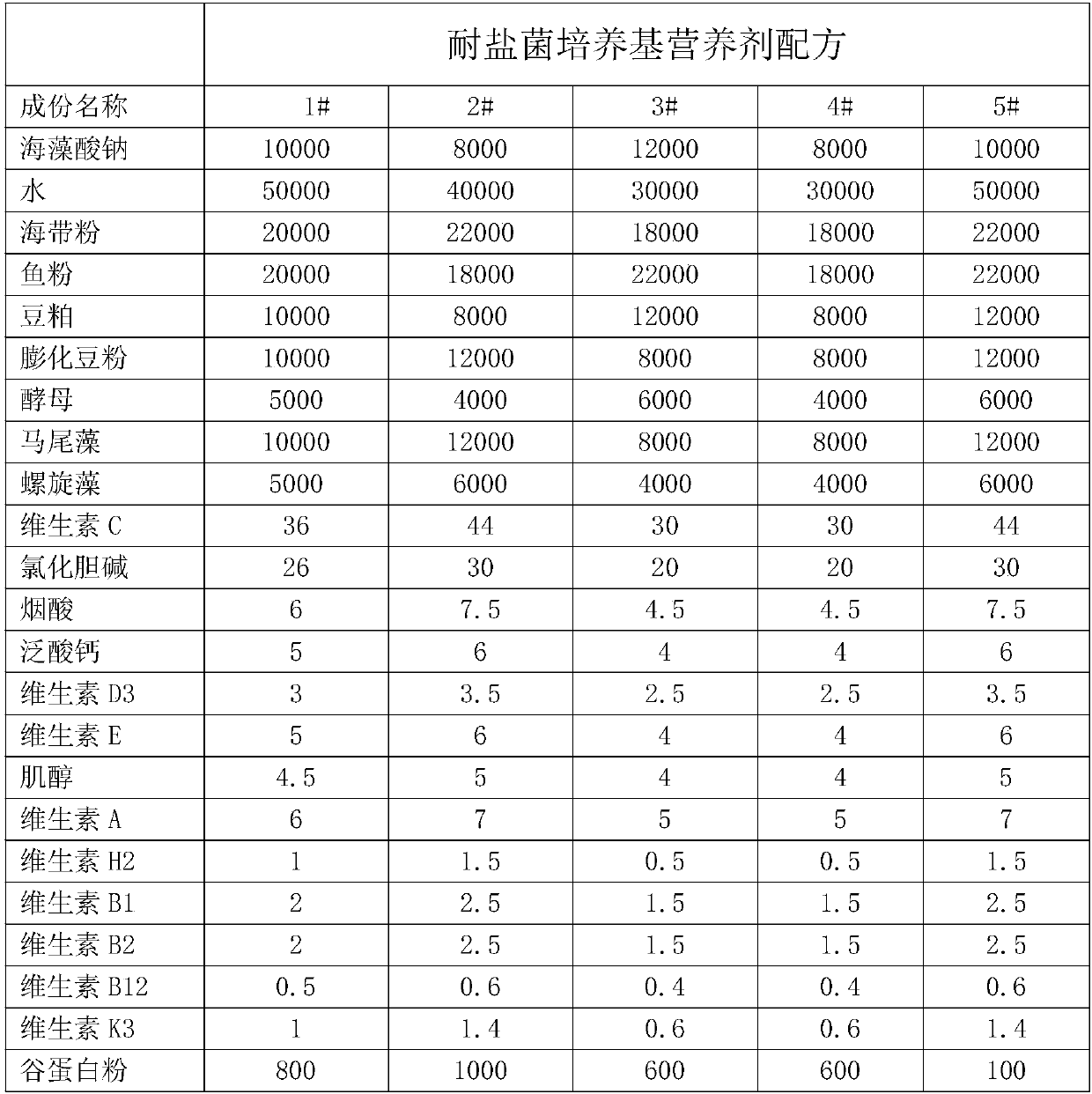

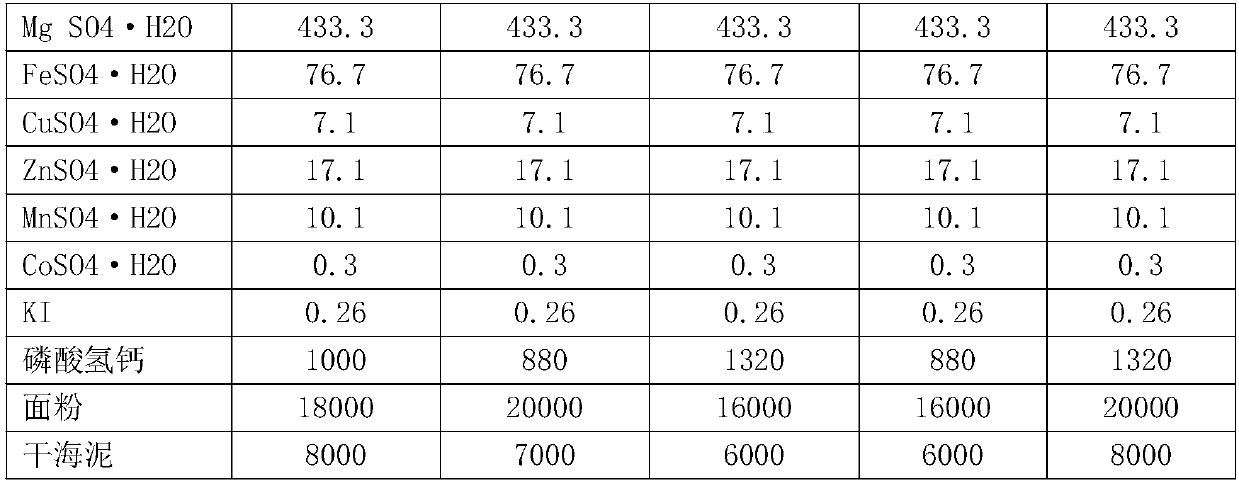

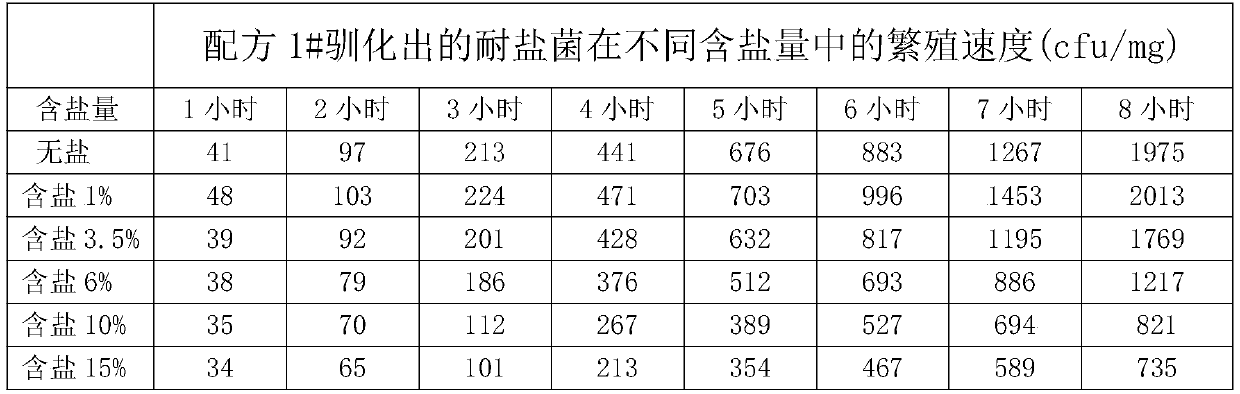

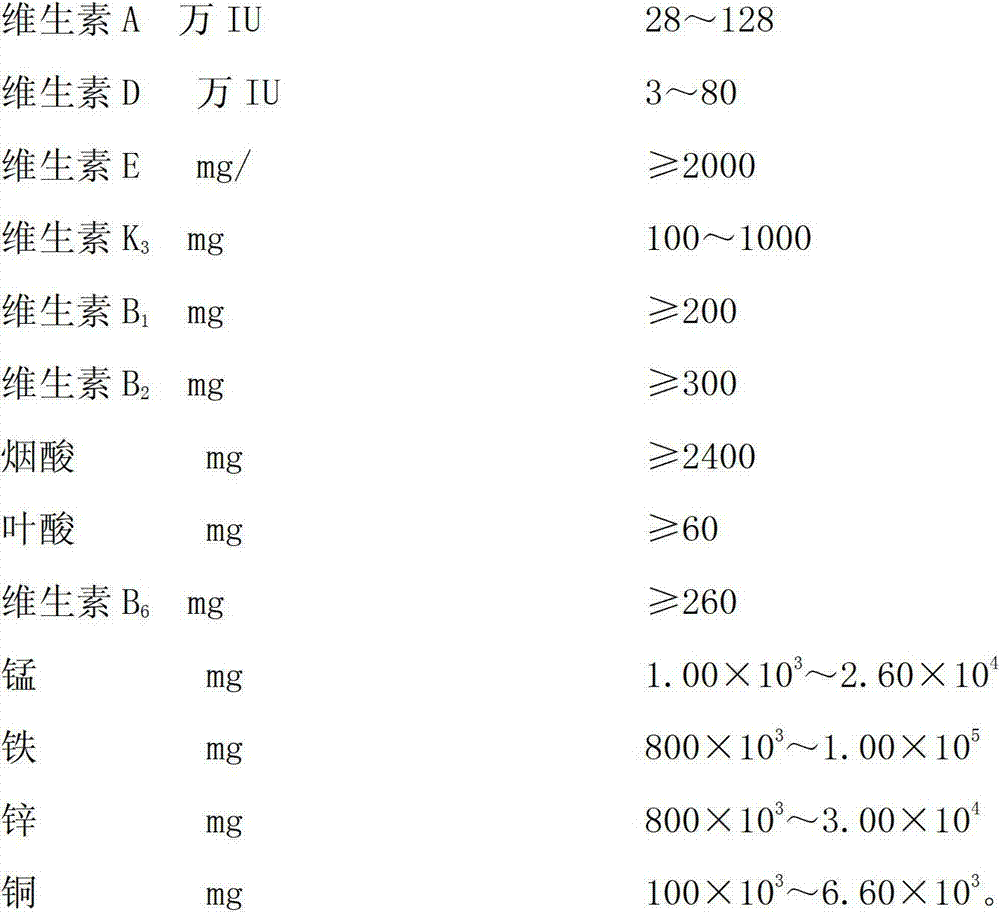

Halotolerant bacteria culture medium nutrient, preparation method, domestication method and application thereof

InactiveCN107603939AMeet processing needsImprove purification effectFungiBacteriaVitamin d 3Vitamin C

The invention discloses a halotolerant bacteria culture medium nutrient, a preparation method, a domestication method and an application thereof. The halotolerant bacteria culture medium nutrient contains the following components in parts by weight: water, sodium alginate, kelp powder, fish meal, bean pulp, expanded bean flour, yeast, gulfweed, spirulina, vitamin C, choline chloride, nicotinic acid, calcium pantothenate, 3 parts of vitamin D, vitamin E, inositol, vitamin A, vitamin H2, vitamin B1, vitamin B2, vitamin B12, vitamin K3, bone protein powder, calcium hydrophosphate, flour, dry seamud and mineral substance microelement metal salt compound. The halotolerant bacteria culture medium nutrient can be used for domesticating various halotolerant bacteria, so that the treatment requirement of high salinity wastewater complex environment can be met and a better purifying effect and higher stability can be achieved.

Owner:钟华

Meat duck compound feed and preparation method thereof

InactiveCN105146219ASolving Feather Pecking ProblemsGuaranteed healthy growthAnimal feeding stuffDigestionSoybean Phospholipids

The first aim of the invention is to provide a meat duck compound feed which is prepared from the following components by weight percent: corns, wheat, sorghum, corn DDGS, soybean meal, guar meal, cottonseed meal, complex enzyme preparation, calcium hydrogen phosphate, salt, soybean phospholipid oil, lysine, rock flour, methionine, threonine, microecologics and compound premix. According to the invention, due to the reasonable matching of all materials, especially the reasonable matching of guar meal and sorghum, all the materials sufficiently exert the efficacies; compound premix, compound enzyme preparation and microecologics are added to the formula, so that vitamin, trace elements and the like are further supplemented and the digestion utilization rate of the feed is improved. The second aim of the invention is to provide a preparation method of the meat duck feed, which adopts a simple process and is suitable for large-scale production; harmful organisms in the feed material can be killed, and the health of animals is benefited; pollution of excrement to the environment can be alleviated, feed cost and breeding cost can be lowered, and breeding benefits can be increased.

Owner:GUANGDONG XIANGDA CAMEL FEED CO LTD

Feed for improving meat quality of fattening pigs and production method thereof

The present invention discloses a feed for improving meat quality of fattening pigs and a production method thereof, and belongs to the technical fields of animal nutrition and feed processing. The feed is produced from corn, soybean meal, soybean oil, perilla oil, wheat bran, nano zeolite adsorbent, calcium hydrogen phosphate, carbonate calcium, salt, selenium-enriched and zinc-enriched mushroom powder, a trace element premix, compound vitamins for gigs, vitamin E, vitamin C, lysine, methionine, a magnesium methionine complex, phytase, sodium sulfate and dry buckwheat powder. The present invention provides a functional feed product which is pollution-free and can improve the quality and color of pork. The pork produced by using the feed meets the quality indicators of national pollution-free foods, and has characteristics that: in lean meat, fat content reaches 6%, polyunsaturated fatty acid content reaches 2%, meat color is higher than grade 4, and selenium content reaches 0.5 PPM.

Owner:贵阳台农种养殖有限公司

Method for preparing high-quality feed-grade calcium hydrophosphate by by-product waste acid of titanium dioxide

ActiveCN102674286AImprove product qualityMeet production requirementsPhosphorus compoundsEconomic benefitsSlurry

The invention provides a method for preparing high-quality feed-grade calcium hydrophosphate by by-product waste acid of titanium dioxide, comprising the following steps of: enabling phosphorite slurry to pre-react; mixing with dilute sulphuric acid, concentrated sulfuric acid and water; and performing desulfurating, filtering, removing impurities, neutralizing, depositing and centrifugally drying on the obtained material. The method overcomes the problem that the titanium dioxide waste acid is difficult to recycle due to high impurity content; the quality of the obtained calcium hydrophosphate meets production requirement of the feed additive completely; and due to the waste produced by titanium dioxide, the method solves the pollution problem of waste sulfuric acid produced by titanium dioxide, develops new recycling path of the waste, reduces adding amount of the make-up water in the water balance of a leaching system due to low-concentration sulfuric acid, reduces water consumption for production, saves cost and improves the economic benefit.

Owner:SICHUAN LOMON PHOSPHORUS CHEM

Pig's feed pre-mixing material and preparing method

InactiveCN1977633AImprove immunityImprove qualityAnimal feeding stuffAccessory food factorsLicorice rootsCopper sulfate pentahydrate

The present invention discloses a pig feed premixed material and its preparation method. It is made up by using blue copperas, copper sulfate monohydrate, zinc sulfate monohydrate, calcium iodate, organic selenium, choline chloride, enzyme preparation, calcium hydrogen phosphate, stone powder, edible salt, astragalus root, lonicera flower, licorice root and zeolite powder according to a certain mixing ratio through a certain preparation process. Said invention can raise immunity of pig and can raise quality of pig meat.

Owner:民惠食品(重庆)有限公司

Organic fertilizer suitable for tomato growth and preparation method thereof

InactiveCN104261930ASuitable for synthesisSuitable for plantingExcrement fertilisersBioloigcal waste fertilisersCalcium bicarbonateFermentation

An organic fertilizer suitable for tomato growth is characterized by being composed of the following raw materials in parts by weight: 10 to 15 parts of rotten tree bark, 6 to 8 parts of cotton seed hull, 8 to 10 parts of peanut hull, 6 to 10 parts of dry cow manure, 16 to 20 parts of dry mud, 4 to 6 parts of zeolite powder, 0.05 to 0.08 part of biological fermentation inoculant, 1 to 2 parts of calcium bicarbonate, 0.2 to 0.4 part of sodium humate, 0.1 to 0.3 part of fulvic acid, 0.04 to 0.06 part of manganese sulfate, 0.02 to 0.05 part of ferrous sulfate, 2 to 3 parts of urea, 0.4 to 0.5 part of auxiliary agent, and a proper amount of water. The fertilizer is suitable for tomato growth, and is prepared by fermenting rotten tree bark, cotton seed hull and peanut hull and then adding inorganic materials into the fermented mixture. Chemical agents are added so as to implement elements (N, P, and K) which are required during the plant growth process. The organic fertilizer must be the development core of fertilizers in the future.

Owner:凤阳县兴科农业生态发展有限公司

Irregular protein raw material compound pig growing and fattening fodder

ActiveCN103039764ANutritional balanceIncrease profitFood processingAnimal feeding stuffAdditive ingredientPeanut meal

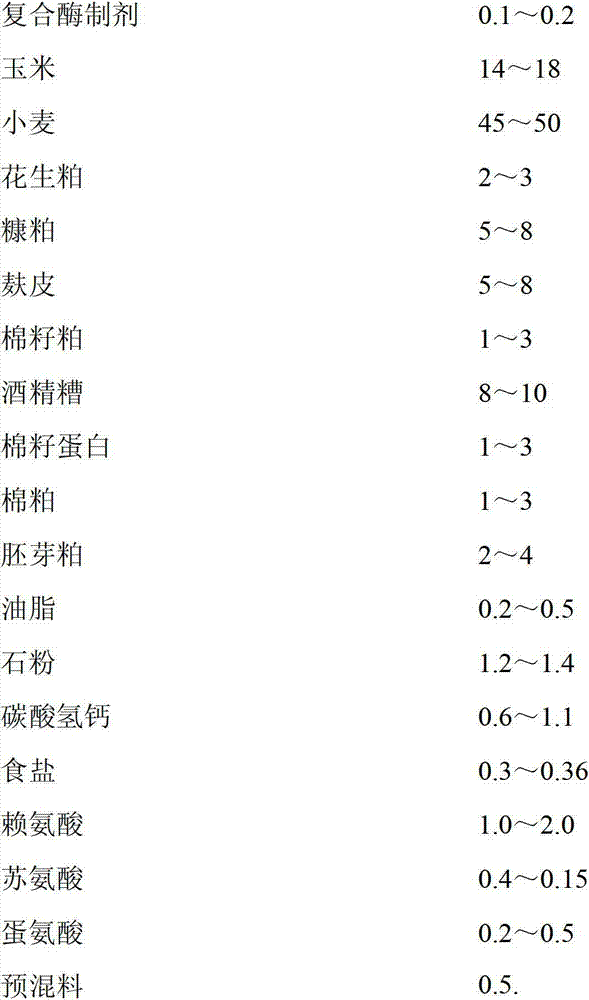

The invention provides an irregular protein raw material compound pig growing and fattening fodder and belongs to a special fodder for special animals. The irregular protein raw material compound pig growing and fattening fodder is characterized in that a raw material formula contains corn with low content and does not contain soya bean meal, fish meal and meat or bone meal, and is prepared from the following raw materials in parts by mass: 0.05-0.3 part of complex enzyme preparation, 10-20 parts of the corn, 10-55 parts of wheat, 1-3 parts of peanut meal, 5-10 parts of bran meal, 5-8 parts of wheat bran, 1-3 parts of cottonseed meal, 5-10 parts of distiller grain, 1-3 parts of cottonseed protein, 1-3 parts of cotton meal, 0-4 parts of plumule meal, 0-0.5 part of grease, 1.0-1.4 parts of stone powder, 0.5-1.1 parts of calcium hydrogen phosphate, 0.3-0.36 part of table salt, 0.5-2.0 parts of lysine, 0.1-0.15 part of threonine, 0-0.5 part of methionine and 0.5 part of premix. The invention provides the irregular protein raw material compound pig growing and fattening fodder which can completely replace the soya bean meal, the fish meal and the meat and bone meal in a regular protein fodder, has balanced nutritional ingredients and high utilization rate, and does not contain anti-nutritional factors. The irregular protein raw material compound pig growing and fattening fodder has the advantages of energy conservation, environmental protection and reduction of production cost.

Owner:SHANDONG LONGSHENG FARMING GRP

Novel microorganism water quality modifier for aquaculture

InactiveCN105271531AImprove the environmentReduce manufacturing costBiological water/sewage treatmentWater qualityMagnesium stearate

The present invention relates to a microorganism water quality modifier, particularly to a novel microorganism water quality modifier for aquaculture. The novel microorganism water quality modifier comprises main raw materials, fillers, and auxiliary materials, wherein the main raw materials comprise Bacillus subtilis, Baclicus lincheniformis, Lactobacillus plantarum, Lactobacillus acidophilus and other beneficial bacteria, the fillers comprise zeolite powder, sodium chloride, magnesium sulfate, calcium sulfate, calcium hydrogen phosphate, and sodium sulfate, and the auxiliary materials comprise pregelatinized starch, micro-powder silica gel, dextrin, a starch-lactose complex, glucose, magnesium stearate, and microcrystalline cellulose. According to the present invention, the Bacillus subtilis, the Baclicus lincheniformis, the Lactobacillus plantarum, the Lactobacillus acidophilus and other beneficial bacteria are directly pressed into the tablets with the diameter of 4-12 mm by using the tableting machine under the dry powder state, the tablet is used for the aquaculture field, and the water body environment is improved.

Owner:TIANJIN RONG LEE BIOTECH DEV CO LTD

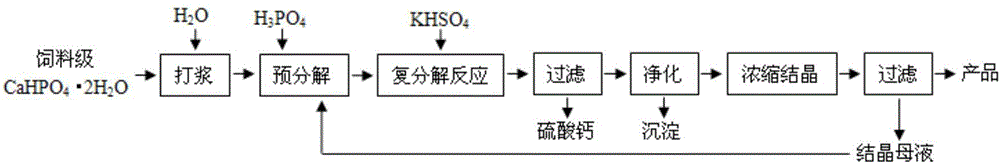

Monopotassium phosphate production method

ActiveCN106744764AHigh recovery rateAchieve recyclingPhosphorus compoundsHydrogen SulfateHydrogen phosphate

The invention relates to a monopotassium phosphate production method. Feed-grade calcium hydrogen phosphate and industrial-grade phosphoric acid are firstly subjected to a pre-decomposition reaction, potassium hydrogen sulfate is added for a double-decomposition reaction, calcium sulfate and filtrate are filtered out, the filtrate is purified, concentrated, cooled and crystallized, a monopotassium phosphate product is prepared, crystallization mother liquor returns to feed-grade calcium hydrogen phosphate for cyclic operation or is used in production of chloride-free compound fertilizer. Compared with the prior art, the recovery rate of phosphorus in feed-grade calcium hydrogen phosphate is substantially increased to 95% or above through pre-reaction of phosphoric acid and feed-grade calcium hydrogen phosphate, besides, the yield of potassium in potassium hydrogen phosphate reaches 99.5%, meanwhile, phosphoric acid is recycled, emission of waste liquor is avoided, the technological process is simple, the yield of phosphorous and potassium in raw materials is high, the production cost can be substantially reduced, and the method is environment-friendly and sustainable and has great competitive advantages.

Owner:EAST CHINA UNIV OF SCI & TECH +1

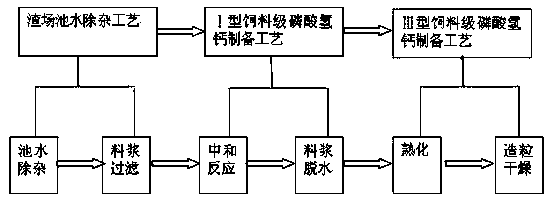

Method for producing feed grade calcium hydrophosphate

The invention discloses a method for producing feed grade calcium hydrophosphate III. The method comprises the steps as follows: slag field tank water and lime milk are mixed in a reactor and defluorinated, and after the obtained slurry is deposited, an supernatant liquid and the lime milk react in the reactor to obtain feed grade calcium hydrophosphate I, then react with phosphoric acid, and are dried, filtered and separated to obtain feed grade calcium hydrophosphate III. Compared with other methods of preparing feed grade calcium hydrophosphate III with wet process phosphoric acid, the method produces the feed grade calcium hydrophosphate I by utilizing phosphogypsum slag filed tank water with a low phosphorous content, treating and improving the content of the phosphorus are needless, the feed grade calcium hydrophosphate I can be directly produced only after purity removal, the product process is simple, and the phosphorus resource can be effectively reused. Moreover, the method is short in curing time, easy to control the process, and free of waste discharge during the whole process.

Owner:WENGFU (GRP) CO LTD

Flour used specially for making deep-fried dough sticks, and its production method

InactiveCN101044866AGreat tastePure wheat flavorDough treatmentSodium bicarbonateMonobasic calcium phosphate

A wheat flour dedicated for deep-fried twisted dough sticks is prepared from the special-grade wheat flour, puffing agent and yeast through grinding sodium bicarbonate and calcium hydrogen phosphate, sieving, adding special-grade refined flour, stirring to obtain puffing agent, adding special-grade wheat flour, tartaric acid and yeast, and stirring.

Owner:楚高波

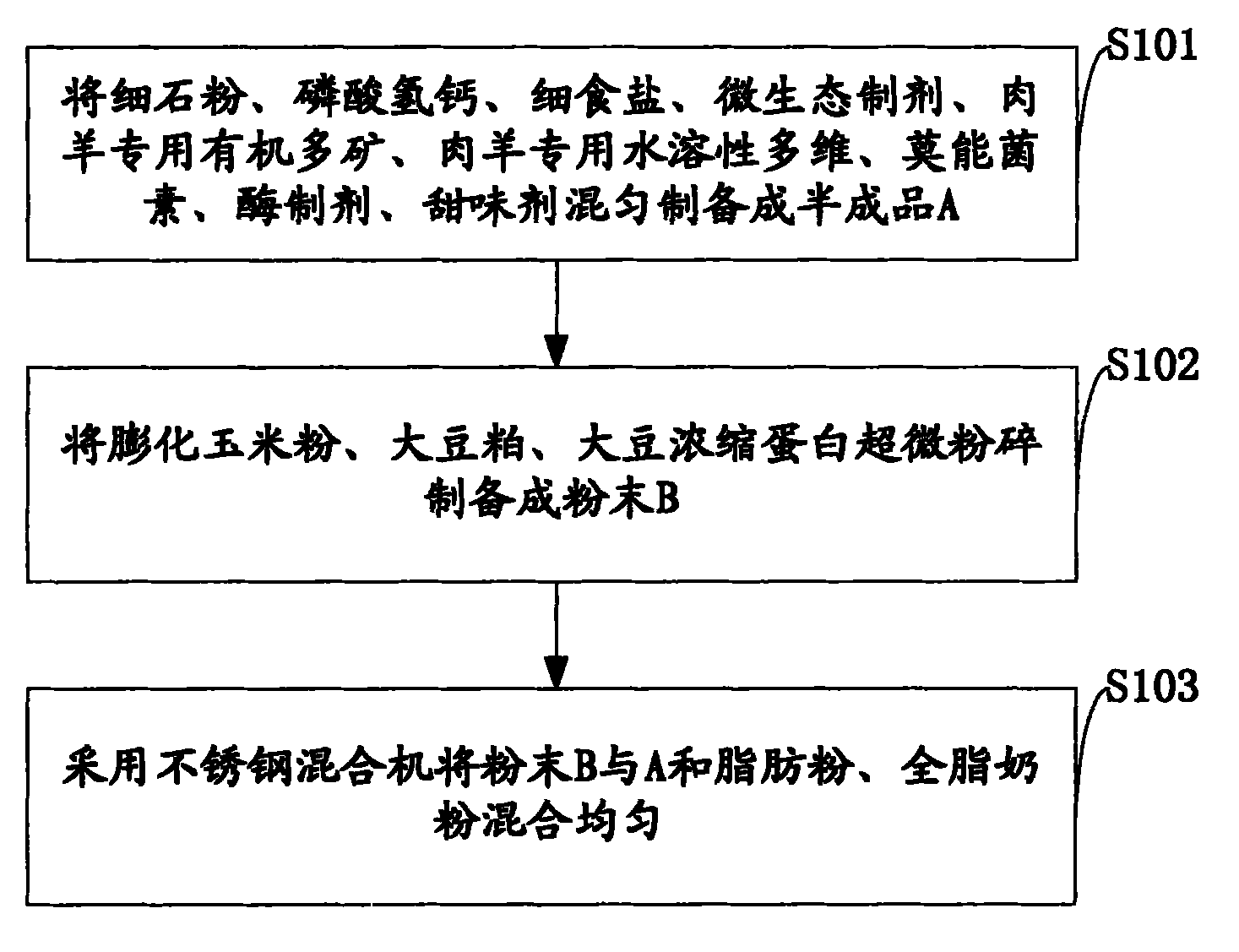

Formula of special milk replacer for meat sheep and preparation method of special milk replacer

InactiveCN103238751AGreat tasteLong fat fastAnimal feeding stuffAdditive ingredientBULK ACTIVE INGREDIENT

Owner:NORTHWEST A & F UNIV

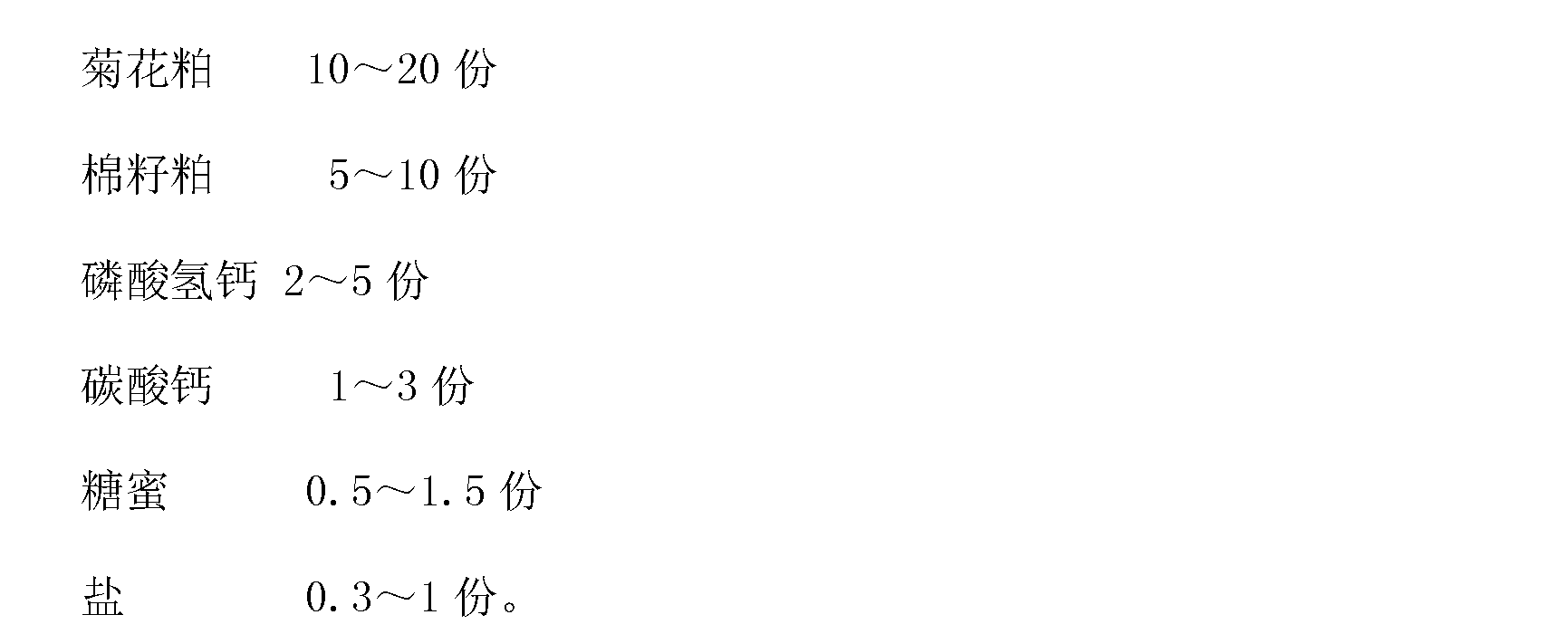

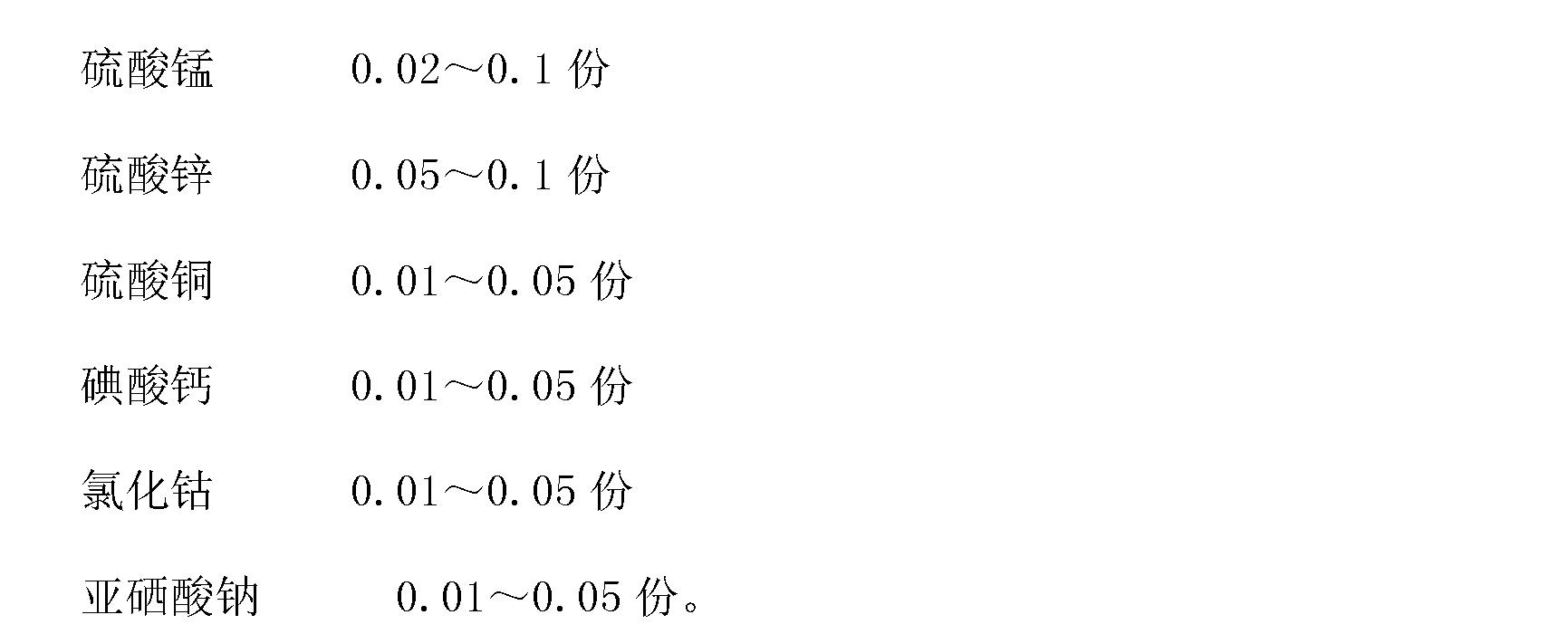

Beef cattle concentrated feed containing chrysanthemum meal

InactiveCN102934756AWith herbal propertiesSignificantly clears away heat and fireAnimal feeding stuffManganeseCopper sulfate

The invention relates to a beef cattle concentrated feed containing chrysanthemum meal. According to a formula, the beef cattle concentrated feed is composed of the following materials: corns, wheat, wheat bran, soybean meal, the chrysanthemum meal, cottonseed meal, calcium hydrophosphate, calcium carbonate, molasses, salt, vitamin A, vitamin D3, vitamin E, manganese sulfate, zinc sulfate, copper sulfate, calcium iodate, cobalt chloride and sodium selenite. All the materials are weighed according to the formula, mixed by using a feed mixer, then packaged with bags and sealed. As a proper amount of chrysanthemum meal is added into the beef cattle concentrated feed provided by the invention, the beef cattle concentrated feed is endowed with a certain property of Chinese herbal medicine, can be used to clear summer heat, has the obvious Chinese medicinal functions of clearing heat, removing fire and improving immunity, and has the advantages of preventing intestines problems and simultaneously supplementing the vitamin A which is insufficient in the common feed.

Owner:TIANJIN GUAYUE FEED CO LTD

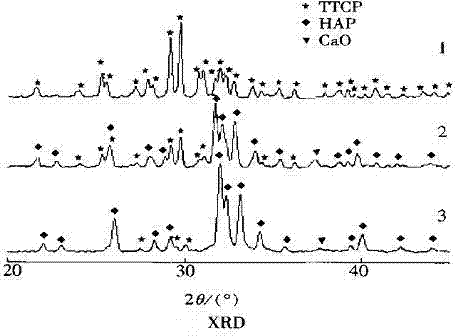

Preparation process of rear earth yttrium ion doped tetracalcium phosphate

InactiveCN103922298AReduce the temperatureInhibit transformationPhosphorus compoundsRare earth metal compoundsPhosphoric acid

The invention discloses a preparation process of rear earth yttrium ion doped tetracalcium phosphate. According to the technical scheme, the preparation process is technically characterized by comprising the following steps: mixing calcium hydrophosphate and analytically pure calcium carbonate according to a molar ration being 1:2; adding yttrium nitrate the addition of which is 0.6-2.5% of the total mass of calcium hydrophosphate and analytically pure calcium carbonate, carrying out ball milling for 6h by using a ball mill in the presence of water serving as a medium; drying for 2h at 80 DEG C in a drying oven; heating the mixture to 1350-1500 at a heating rate of 250 DEG C / h in a high-temperature furnace; and heating heat for 1-6h and cooling in the furnace to finally prepare the rear earth yttrium ion doped tetracalcium phosphate. A rear earth metallic compound yttrium nitrate is introduced in the raw material system of preparation of tetracalcium phosphate, which is beneficial to the reduction of synthesis temperature of tetracalcium phosphate, stabilization of tetracalcium phosphate phase, inhibition of conversion from tetracalcium phosphate to free calcium oxide and hydroxyapatite; in addition, one-time firing is realized without quenching operation, the process difficulty is lowered, and the product cost is reduced.

Owner:HENAN NORMAL UNIV

A kind of goat essence supplement granular material for meat

InactiveCN102258140AIncrease profitImprove efficiencyFood processingAnimal feeding stuffSodium bicarbonateHigh energy

The invention discloses a meat goat pelleted concentrate, and relates to a goat forage, which comprises the following components of: corn, guniting protein, wheat shorts, guniting wheat bran, soybean meal, cottonseed meal, corn germ cake, corn DDGS, castor meal, cottonseed protein, calcium hydrogen phosphate, fine stone flour, salt, sodium bicarbonate, magnesium oxide, ferrous sulfate monohydrate, copper sulfate pentahydrate, manganese sulfate monohydrate, zinc sulfate monohydrate, selenious acid at the concentration of 1%, cow multivitamin, a sweetener, and calcium iodate at the concentration of 1%. The meat goat pelleted concentrate belongs to a forage with high energy, high protein and high amino acid, has abundant nutrients as well as good palatability, grows by rumen microorganisms, and can be used to promote digestion and raise the utilization rate of the forage; when in use, the meat goat pelleted concentrate is mixed with various local crop straw, wicker, and leaves to feed goats; the ratio of the forage used to meat reaches 4.5-5: 1 and goats grow rapidly. Therefore, the cost is reduced and the benefits of raising households are raised.

Owner:山西宏福农牧科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com