Irregular protein raw material compound pig growing and fattening fodder

A technology for protein and fattening pigs, applied in animal feed, animal feed, applications, etc., can solve the problems of low utilization rate of feed nutrients, difficulty in formulating formula structure, pollution of the environment, etc., to overcome low nutritional value, high utilization rate, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

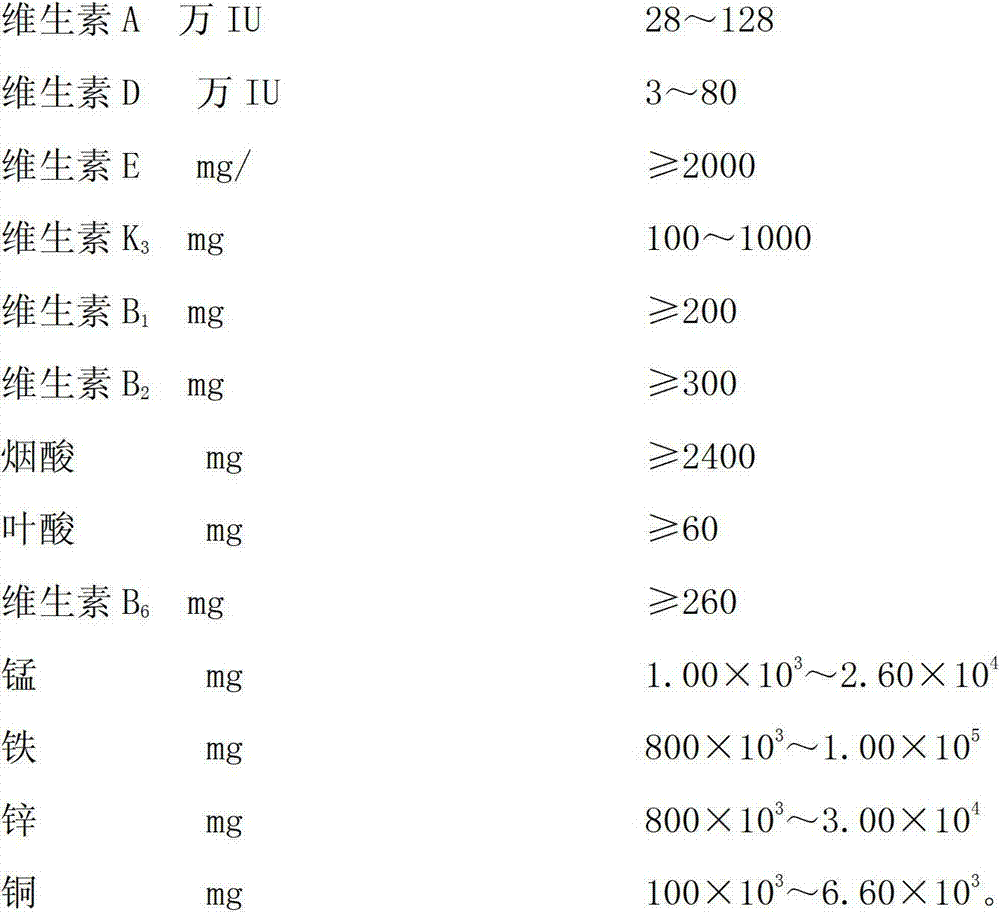

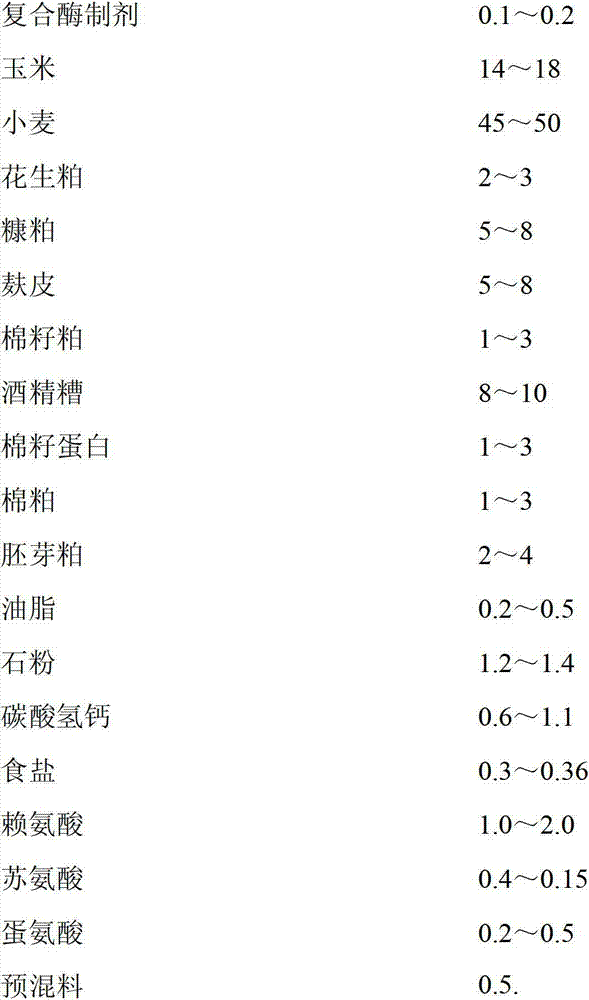

[0045] Embodiment 1 prepares a kind of unconventional protein raw material compound fattening pig feed of the present invention

[0046] Accurately weigh 0.05 kg of dextranase, 0.1 kg of xylanase, 0.05 kg of wheat-type compound enzyme, 18 kg of corn, 40 kg of wheat, 2 kg of peanut meal, and 8 kg of bran meal that have been previously treated and crushed to micron-sized particles. , 8 kg of bran, 3 kg of cottonseed meal, 9.6 kg of distiller's grains, 2 kg of cottonseed protein, and 3 kg of cottonseed meal. Germ meal 2 kg, oil 0.2 kg, stone powder 1.2 kg, calcium hydrogen phosphate 0.6 kg, salt 0.35 kg, lysine 1.0 kg, threonine 0.15 kg, methionine 0.2 kg, premix 0.5 kg; mix well, 85 ℃ After heat treatment at -90°C, granulate. The obtained non-conventional protein material compound fattening pig feed product reaches the following technical indicators:

[0047] Crude protein ≥ 15.0%, crude fat ≥ 2.5%, crude fiber ≤ 7.0%, crude ash ≤ 8.0%, calcium 0.50-1.00%, total phosphorus ≥ 0...

Embodiment 2-9

[0049] According to the method and steps of Example 1, and according to the formula in Table 1, the non-conventional protein raw material composite fattening pig feed of the present invention was prepared.

[0050] Table 1

[0051] raw material

Example 2

Example 3

Example 4

Example 5

Example 6

Example 7

Example 8

0.02

0.05

0.06

0.05

0.05

0.05

0.06

0.1

0.08

0.08

0.1

0.1

0.1

0.1

Wheat type compound enzyme

0.1

0.1

0.1

0.1

0.1

0.1

0.1

corn

45.74

29.5

24.3

18.9

14.6

24.5

9

wheat

11

25

32

40

44

31

51.3

5

4

3

3

4

4

3

[0052] Bran meal

11

11

12

10

11

12

11

1

2

1

2

1

2

1

distiller's grains

10

10

10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com