Method for deeply removing phosphorus in coarse sodium tungstate solution

A sodium tungstate solution technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of large amount of sedimentation slag, large tungsten loss, loss, etc., achieve high phosphorus removal efficiency, short reaction time, Good phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of method of thick sodium tungstate solution deep phosphorus removal, comprising:

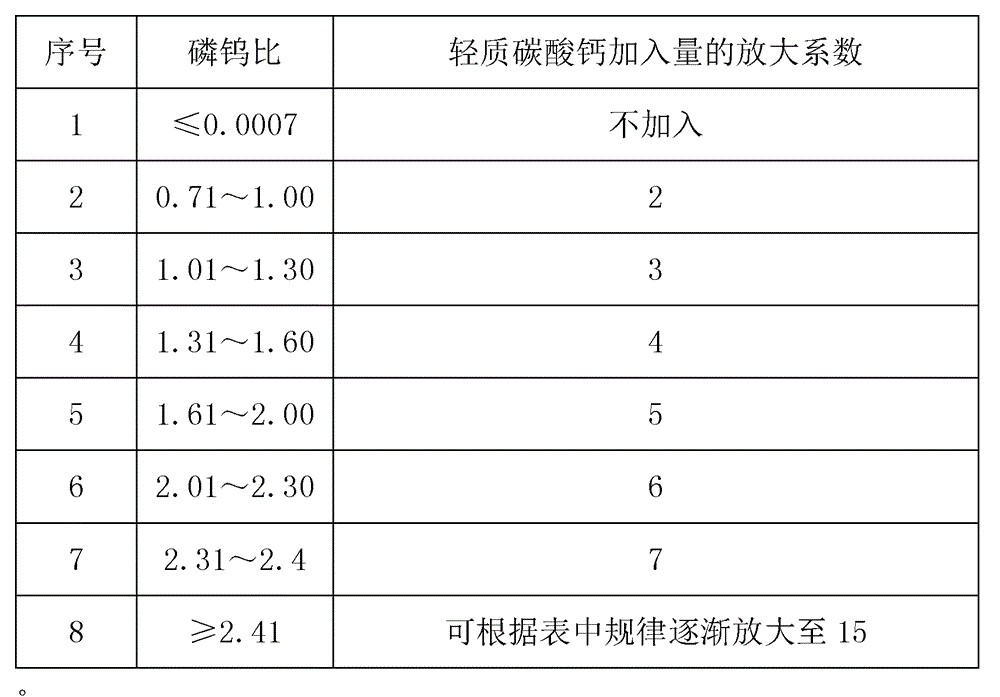

[0022] (1) In the process of producing ammonium paratungstate by ion exchange method, the mass ratio of phosphorus to tungsten is greater than 0.0007[P / WO 3 ≥0.0007%] crude sodium tungstate solution must be equipped with special phosphorus removal operations;

[0023] (2) Phosphorus removal reaction conditions: temperature 90±5°C, the amount of phosphorus removal agent added is 2.5 times the mass of phosphorus in the crude tungstic acid solution, and the stirring time is 30 minutes; light calcium carbonate is selected as the phosphorus removal agent, which has a short reaction time , Fast speed and high phosphorus removal efficiency;

[0024] (3) The feed liquid after the reaction is filtered through a plate and frame filter press to realize liquid-solid separation, and a new solution and a precipitated residue with a phosphorus content less than 0.06g / l are obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com