Method for producing feed grade calcium hydrophosphate

A technology of calcium hydrogen phosphate and feed grade, which is applied in the production of calcium hydrogen phosphate and calcium dihydrogen phosphate mixture, and the field of feed grade calcium hydrogen phosphate III type products, can solve the problems of phosphorus production and low phosphorus utilization rate, and achieve the curing time. The effect of short, simple production process and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

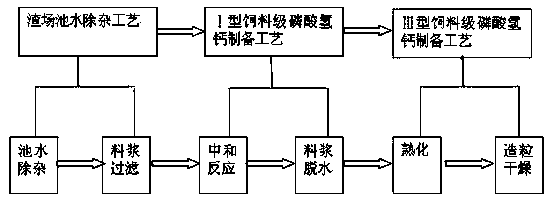

[0012] Process flow chart of the present invention is as figure 1 shown.

[0013] Raw materials: phosphogypsum slag yard pool water, containing 1.7% phosphorus, lime, containing calcium oxide ≧ 85%

[0014] ① Impurity removal process for slag yard pool water:

[0015] a. Pool water removal process: pool water, lime dosage ratio is pool water: lime = 1: 0.01-0.02, appropriate amount of sodium sulfide;

[0016] Control conditions: the pressure is normal pressure, the reaction temperature is 30-60°C, and the reaction time is 1-2.5 hours;

[0017] b. Slurry filtration: The filtration equipment is an automatic backwash filter, and after filtration, a clear liquid with a phosphorus content of about 1.2% is obtained.

[0018] ② Feed grade calcium hydrogen phosphate type I preparation process:

[0019] The clear liquid obtained by filtering is mixed with a certain concentration of lime milk, the pH value is adjusted between 5.5-6.3, and the reaction time is controlled for 1-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com