Production method for eggs rich in DHA and Vitamin E ingredients

A production method and technology of vitamins, applied in applications, animal feed, animal feed, etc., can solve problems such as oxidative deterioration, DHA oxidative deterioration, and shorten product shelf life, so as to improve stability, ensure health, and extend product shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

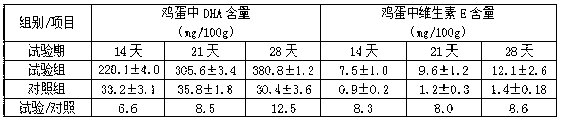

Embodiment 1

[0014] a. During the laying period of the laying hens, feed the laying hens the feed of the following formula;

[0015] In terms of mass ratio: corn 500, soybean meal 200, feed corn gluten meal 15, rice bran meal 20, corn DDGS 20, wheat bran 20, stone powder 65, calcium hydrogen phosphate 5, fish oil 15, linseed 30, salt 2, methionine 0.8, Vitamin premix 0.3, adsorption vitamin E powder 0.1, trace element premix 1, choline chloride 1, Yijunle Bio-Aid 0.5, Coviase 0.25, phytase 0.1, compound betaine 0.2;

[0016] b. After three weeks, collect the eggs produced by the laying hens.

[0017] The sources of raw materials are as follows:

[0018] raw material name supplier corn Dalian Hesheng Grain and Oil Trade Co., Ltd. soybean meal Jiusan Group Dalian Soybean Technology Co., Ltd. corn gluten meal for feed Changchun Yucheng Starch Sugar Co., Ltd. rice bran meal Dalian Xinda Feed Co., Ltd. Corn DDGS Meihekou Fukang Alcohol Co., Ltd. ...

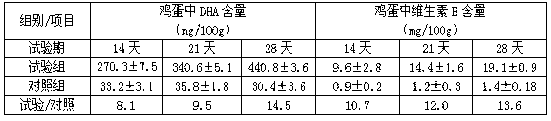

Embodiment 2

[0020] a. During the laying period of the laying hens, feed the laying hens the feed of the following formula;

[0021] In terms of mass ratio: corn 650, soybean meal 240, feed corn gluten meal 20, rice bran meal 30, corn DDGS 50, wheat bran 30, stone powder 70, calcium hydrogen phosphate 15, fish oil 100, linseed 100, salt 4, methionine 1, Vitamin premix 0.5, adsorption vitamin E powder 0.5, trace element premix 1.5, choline chloride 2, Yijunle Bio-Aid 1, coviase 0.5, phytase 0.2, compound betaine 0.4;

[0022] b. After three weeks, collect the eggs produced by the laying hens.

[0023] The source of raw materials is the same as in Example 1.

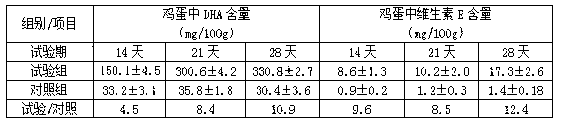

Embodiment 3

[0025] a. For laying hens aged 23 to 45 weeks, feed the feed of the following formula. At this stage, laying hens have strong metabolism, high nutrient absorption and conversion rate, and strong disease resistance;

[0026] In terms of mass ratio: corn 600, soybean meal 220, feed corn gluten meal 18, rice bran meal 25, corn DDGS 25, wheat bran 25, stone powder 68, calcium hydrogen phosphate 10, fish oil 55, linseed 80, salt 3, methionine 0.9, Vitamin premix 0.4, adsorption vitamin E powder 0.3, trace element premix 1.0, choline chloride 1.5, Yijunle Bio-Aid 0.8, Kewei enzyme 0.4, phytase 0.15, compound betaine 0.3;

[0027] b. After three weeks, collect the eggs produced by the laying hens.

[0028] The source of raw materials is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com