System and method for increasing nitric phosphate product P2O5 dissolvability in water

A technology of P2O5, nitrophosphate fertilizer, applied in the field of nitrophosphate fertilizer production, can solve the problems of affecting product quality, reducing water solubility, low water solubility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

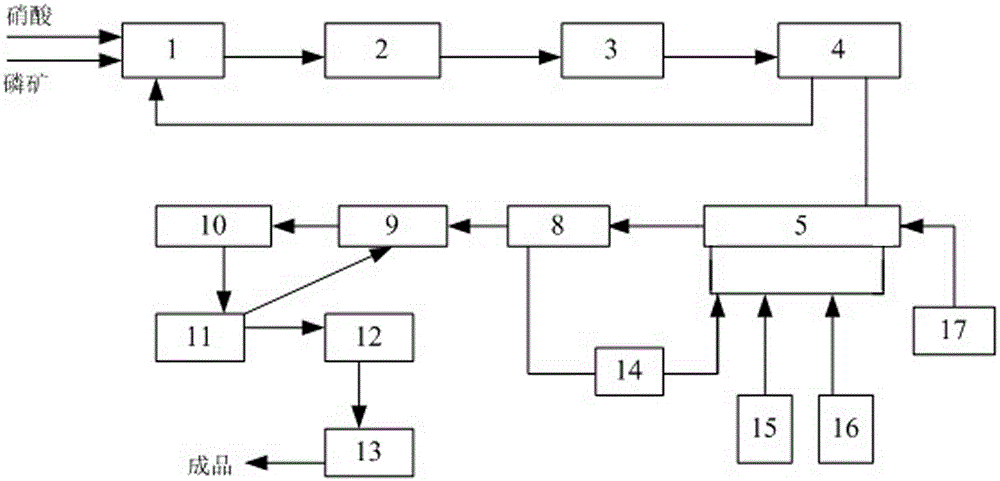

[0050] Improve nitrophosphate fertilizer product P 2 o 5 For the water-soluble rate system, the nitric acid with a concentration of 62% and phosphate rock are acidified in the acid hydrolysis tank. Since the phosphate rock contains impurities such as iron, aluminum and silicon, acid insolubles will be produced after acid hydrolysis; the acid hydrolysis tank The acid solution overflowed in 1 is drained to the acid insoluble matter settling tank 2 for natural settlement, the acid insoluble matter in the lower layer is collected and discharged, and the supernatant liquid flows into the crystallizer 3, and the ammonia water with a mass fraction of 20% is used as the coolant Carry out heat exchange crystallization cooling with acidolysis solution; The calcium nitrate crystal suspension after the crystallization is drained in the calcium nitrate filter 4 from the crystallizer 3, the calcium nitrate filter cake formed by filtration is converted into ammonium nitrate through method tr...

Embodiment 2

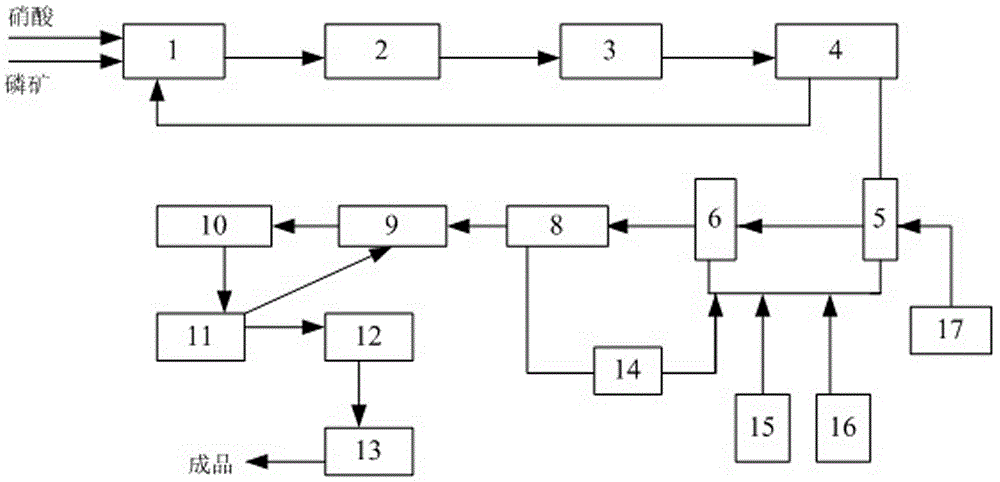

[0052] Improve nitrophosphate fertilizer product P 2 o 5 For the water-soluble rate system, the nitric acid with a concentration of 60% and the phosphate rock are acidolyzed in the acid hydrolysis tank 1. Since the phosphate rock contains impurities such as iron, aluminum and silicon, acid insolubles will be produced after acid hydrolysis; The acid solution overflowed in the tank 1 is diverted to the acid insoluble matter settling tank 2 for natural settlement, the acid insoluble matter in the lower layer is collected and discharged, and the supernatant liquid flows into the crystallizer 3, and is cooled by ammonia water with a mass fraction of 20% Carry out heat exchange and crystallization cooling with the acid solution; the calcium nitrate crystal suspension after crystallization is drained from the crystallizer 3 to the calcium nitrate filter 4, and the calcium nitrate filter cake formed by filtration is converted into ammonium nitrate through method treatment, The mother...

Embodiment 3

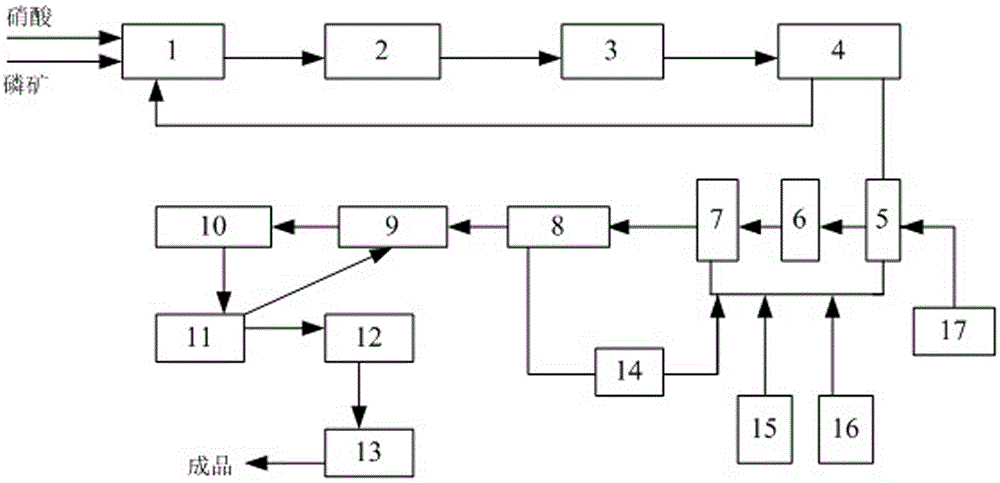

[0054] Improve nitrophosphate fertilizer product P 2 o 5 For the system with water solubility, acid hydrolyze the nitric acid and phosphate rock with a concentration of 60% in the acidolysis tank 1. Since the phosphate rock contains impurities such as iron, aluminum and silicon, acid insolubles will be produced through acid hydrolysis; The acid solution overflowed in the tank 1 is diverted to the acid insoluble matter settling tank 2 for natural settlement, the acid insoluble matter in the lower layer is collected and discharged, and the supernatant liquid flows into the crystallizer 3, and is cooled by ammonia water with a mass fraction of 20% Carry out heat exchange and crystallization cooling with the acid solution; the calcium nitrate crystal suspension after crystallization is drained from the crystallizer 3 to the calcium nitrate filter 4, and the calcium nitrate filter cake formed by filtration is converted into ammonium nitrate through method treatment, The mother liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com