Fermentation trace element premix and preparation method thereof as well as fermentation composite premix and preparation method thereof

A composite premix, trace element technology, applied in animal feed, animal feed, applications, etc., can solve problems such as toxicity, impact on human health, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

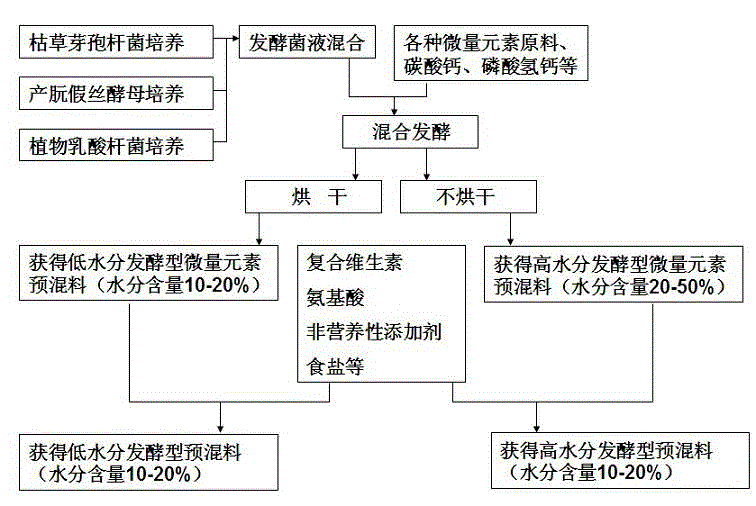

Method used

Image

Examples

Embodiment 1

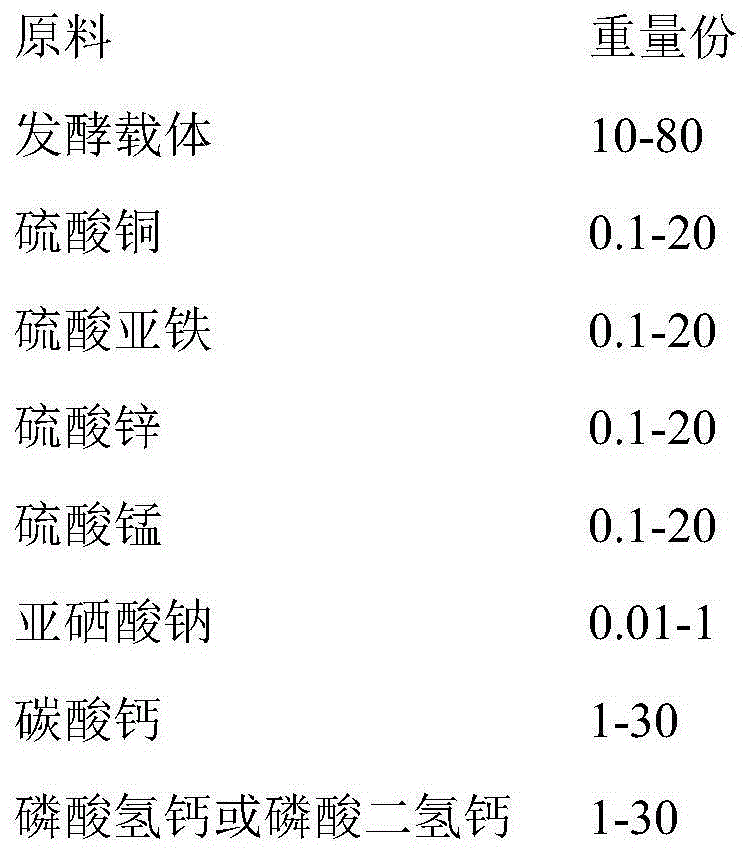

[0077] A fermented trace element premix is made from the following raw materials in parts by weight:

[0078]

[0079] A preparation method for fermented trace element premix, the steps are:

[0080] 1. Prepare respectively the fermented liquid of Bacillus subtilis, Lactobacillus plantarum and saccharomyces;

[0081] 2. Add the above-mentioned raw materials to the blender or mixer according to the addition ratio, except for the fermentation liquid of Bacillus subtilis, the fermentation liquid of Lactobacillus plantarum, and the fermentation liquid of Candida utilis, and mix well for about 3-10 minutes;

[0082] 3. Add the prepared Bacillus subtilis fermentation broth, Lactobacillus plantarum fermentation broth, and Candida utilis fermentation broth, mix thoroughly for 3-10 minutes, and adjust the water content to 25-50%;

[0083] 4. After bagging, tie the mouth of the bag tightly, ferment at room temperature or in a greenhouse at 20-40 degrees for 2-7 days, dry or not. ...

Embodiment 11

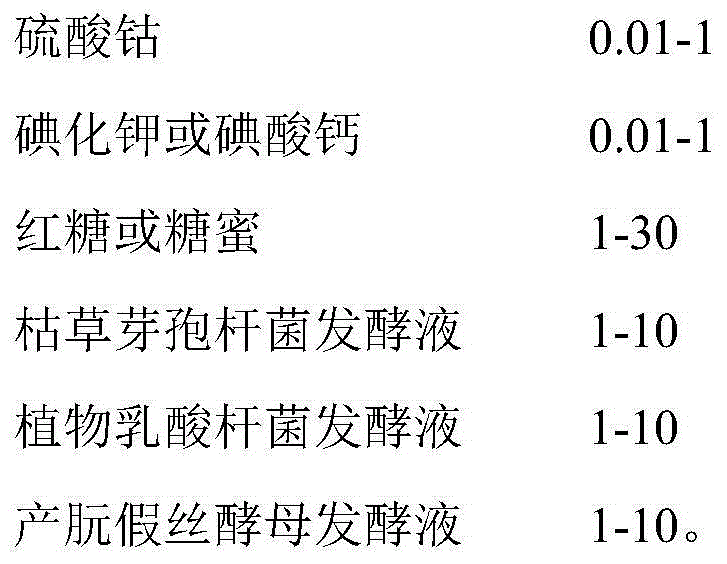

[0088] A fermented composite premix, which is made of the following raw materials in parts by weight:

[0089]

[0090]

[0091] A preparation method for a fermented trace element premix and a fermented compound premix, the steps of which are:

[0092] 1. Strain selection: select Bacillus subtilis (hereinafter referred to as bacterial strain A), saccharomyces (hereinafter referred to as bacterial strain B), and lactic acid bacteria (hereinafter referred to as bacterial strain C) with good effect of degrading sulfate. Commercialized or publicly reported strains or strains with the functions screened in a conventional manner can accomplish the present invention.

[0093] 2. Liquid fermentation of bacterial strains: carry out conventional liquid fermentation on the selected bacterial strains A, B and C respectively to produce liquid fermented seed liquid.

[0094] The composition of the LB medium used for the strain A is: tryptone 10g, yeast extract 5g, sodium chloride 10g...

Embodiment 21

[0111] Preparation of strain A fermentation broth:

[0112] Get 2ml bacterial strain A (viable bacteria concentration is 10 10 CFU / ml), inoculated in 100ml medium for shake flask fermentation culture, the fermentation temperature is 28-37°C, the pH value is 7.2, the rotation speed is 200-300r / min, and the fermentation time is 24-36h. The shake flask fermentation medium is LB medium, the ingredients are: tryptone 10g, yeast extract 5g, sodium chloride 10g, distilled water 1000ml, and the pH value is 7.2.

[0113] After the shake flask fermentation is completed, carry out the expansion culture of the fermenter. Take 100ml of the shake flask fermentation seed liquid and inoculate it into a 10L fermenter with a liquid volume of 5L. min, ferment for 24-36 hours. The composition of the medium in the pilot test of the fermenter was the same as that of the shake flask fermentation medium. After the fermentation, the medium was kept at 4°C for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com