Cereal sweet wine, solid-state cereal sweet wine, cereal clear wine and preparation method thereof

A technology for miscellaneous grains and sweet wine, applied in the field of fermented food processing, can solve the problems of difficulty in obtaining the pure sweet wine flavor of traditional glutinous rice sweet wine, loss of natural shape or good flavor, and single taste of rice wine, and achieve good taste and improved intestinal tract. function, and the effect of improving the germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

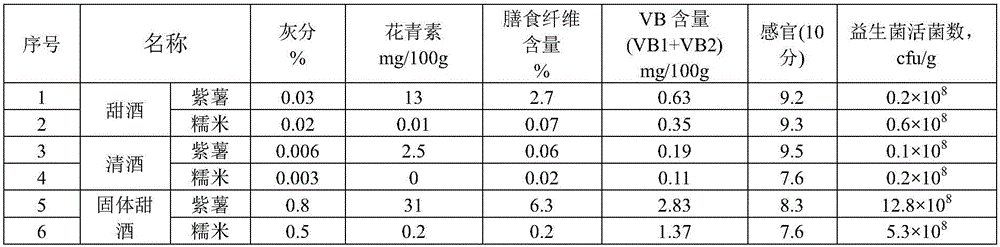

[0041] The making of embodiment 1 purple sweet potato liqueur, clear wine, solid wine

[0042] Process formula (1 part = 10g):

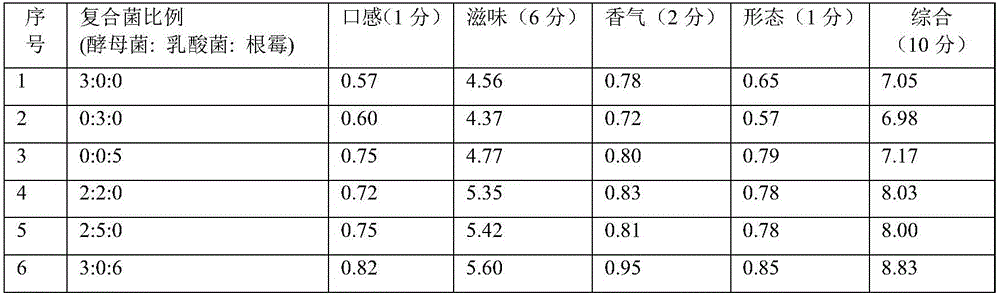

[0043] 100 parts of glutinous rice; 100 parts of purple potato rice; compound bacteria: 0.5 parts each of rhizopus, lactic acid bacteria and yeast;

[0044] Preparation materials: 5 parts of white sugar, 1 part of protein, 1 part of dietary fiber powder, vitamin powder (VB 1 0.0005 copies, VB 2 0.0005 parts), fruit and vegetable powder 1 part.

[0045] The preparation method comprises the following steps:

[0046] 1) Preparation of miscellaneous grain rice: crush the purple sweet potato and pass it through a 100-mesh sieve, mix the prepared substances evenly, add it to the purple sweet potato powder, extrude it with an extruder, and control the temperature (60°C for the first stage, 60°C for the second stage and Three sections of 150 ° C, 0.2min, pressure 2Mpa, made into granules, material length 0.9cm, width 0.5cm, height 0.3cm, water content 28...

Embodiment 2

[0055] The influence of embodiment 2 germination on the quality of solid liqueur

[0056] Germinated mung bean liqueur craft recipe:

[0057] 100 parts of glutinous rice; 20 parts of mung beans; compound bacteria: 0.5 parts each of rhizopus, lactic acid bacteria and yeast;

[0058]Preparation materials: 5 parts of white sugar, 1 part of protein, 1 part of dietary fiber powder, vitamin powder (VB 1 0.001 copies, VB 2 0.001 part), 3 parts of fruit and vegetable powder;

[0059] Nutrients: 0.0001 part of sodium glutamate, 0.0001 part of calcium lactate.

[0060] 1) Miscellaneous grains treatment: Add water to the nutrients to prepare a nutrient solution. The concentration of sodium glutamate in the nutrient solution is 10mmol / L, and the concentration of calcium ions is 0.05mmol / L. Add mung beans for soaking, and the solid-liquid ratio is 1:3. Soak to obtain material 1;

[0061] 2) Production of miscellaneous grain rice: Dry material 1, crush it through a 100-mesh sieve, mix ...

Embodiment 3

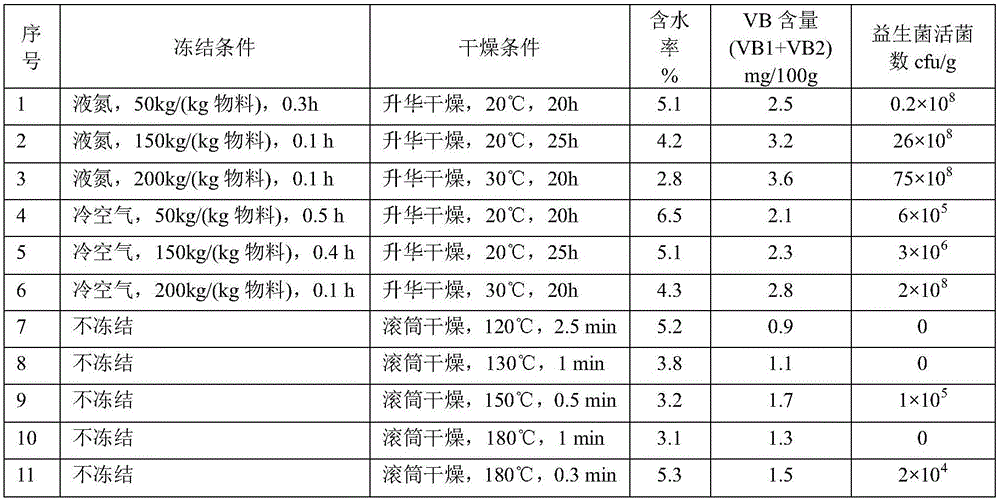

[0069] Example 3 The effect of drying on the number of probiotics and the content of VB in solid miscellaneous grain wine

[0070] Corn Cordial Craft Recipe:

[0071] 100 parts of glutinous rice; 50 parts of corn; compound bacteria: 0.5 parts each of rhizopus, lactic acid bacteria and yeast;

[0072] Preparation materials: 5 parts of white sugar, 1 part of protein, 1 part of dietary fiber powder, vitamin powder (VB 1 0.0005 copies, VB 2 0.0005 parts), fruit and vegetable powder 1 part.

[0073] Except that step 4) drying conditions are different (see Table 3), all the other process formulas are according to embodiment 1. The effect of drying on the number of viable bacteria and the content of VB in solid miscellaneous grain wine is shown in Table 3. From Table 3, it can be seen that the retention rate of VB content and the number of viable bacteria in the sublimation drying method is high, and the probiotics in the wine are less retained without freezing treatment.

[0074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com