A rice flour ripening and loosening integrated equipment

A mature and loose technology, applied in the direction of lighting and heating equipment, dry gas arrangement, chemical instruments and methods, etc., can solve the problems of high production cost and inconvenient widespread application, so as to reduce equipment manufacturing cost, improve production quality, simplify The effect of device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

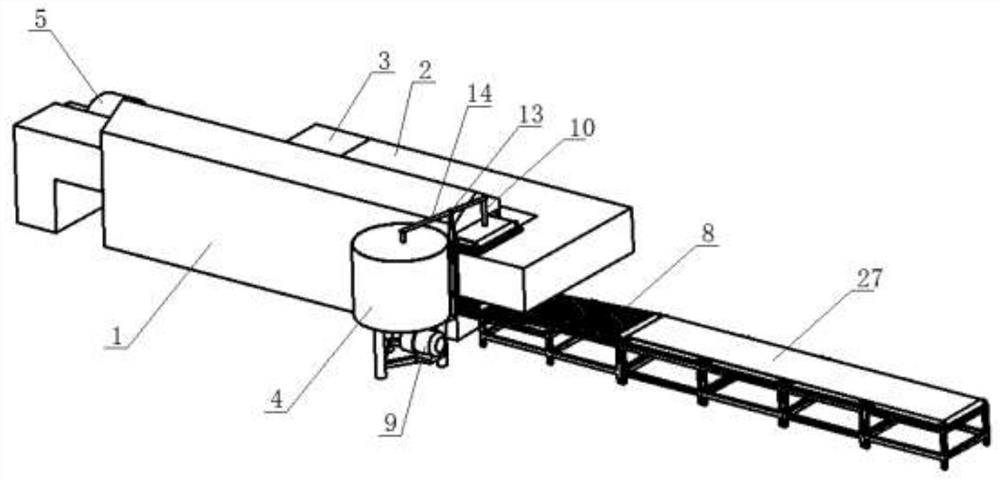

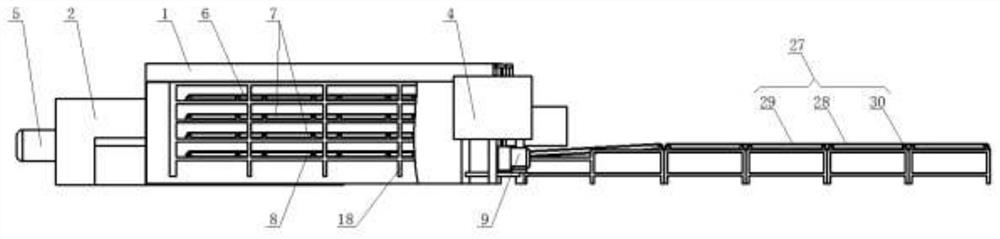

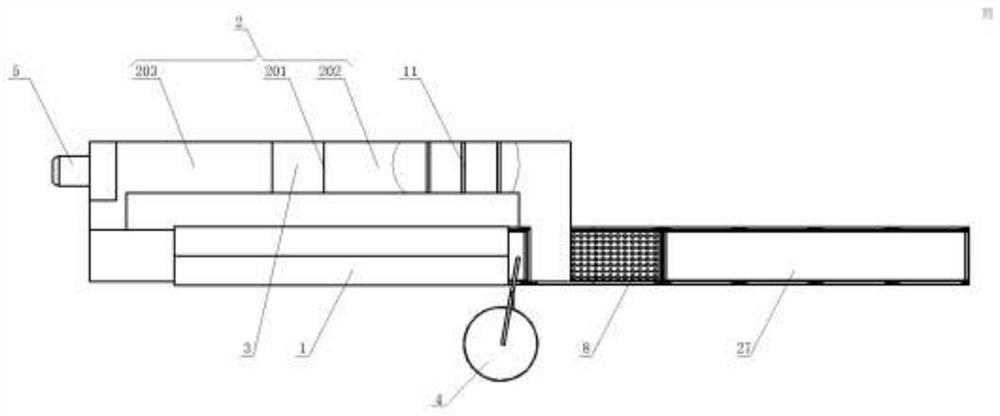

[0024] Such as Figure 1 to Figure 6 As shown, a kind of rice flour ripening and loose integration equipment of the present invention comprises a constant temperature oven 1 and a mixing cylinder 4 with an opening at one end. A frame 18 is arranged inside the constant temperature oven 1, and a feeder is installed on the frame 18 from top to bottom. 6. At least one layer of conveyor 7 and discharge machine 8. Both feeder 6 and discharge machine 8 extend out of the constant temperature oven 1. The feeder 6 includes a feeding cloth 16 and several idlers A17. Both ends of the idler A17 pass through the bearing The seat is installed on the frame 18, the feeding cloth 16 is wound on the outer peripheral surface of the roller A17, the conveyor 7 or the discharge machine 8 includes several rollers B19, and the two ends of the roller B19 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com