Production method for high yield ripened highland barley powder rich in gamma-aminobutyric acid

A production method and technology for curing highland barley, which are applied in the direction of food heat treatment, baking mixture, baking, etc., to achieve the effects of reducing soaking treatment time, high degree of gelatinization, and complete gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

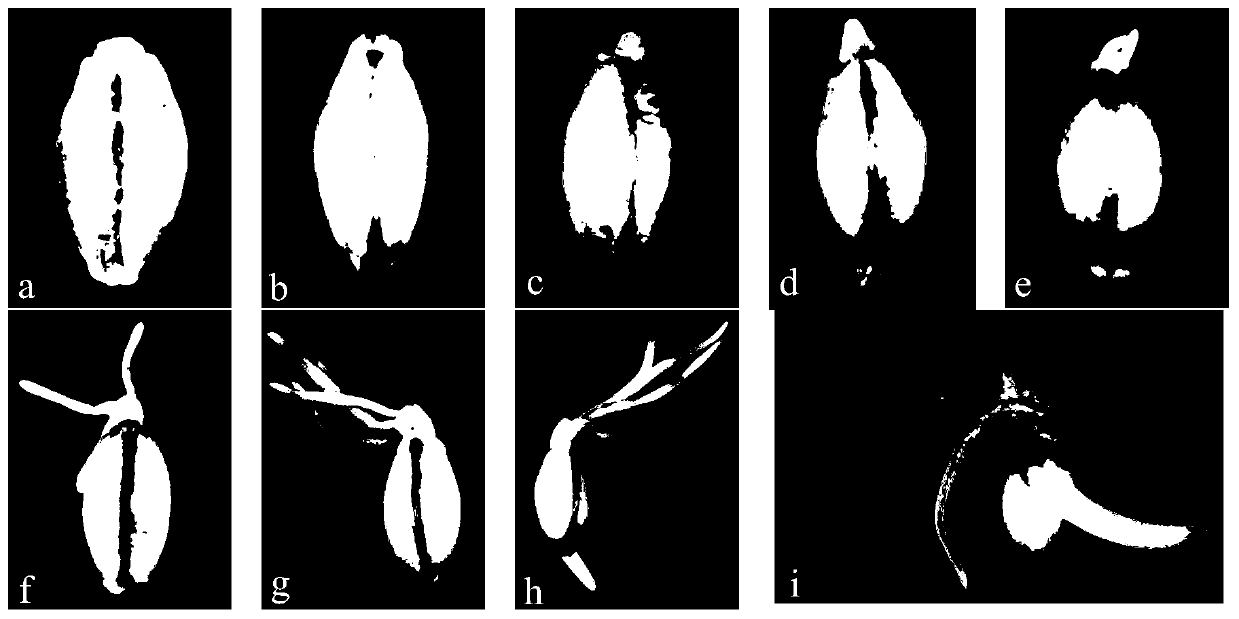

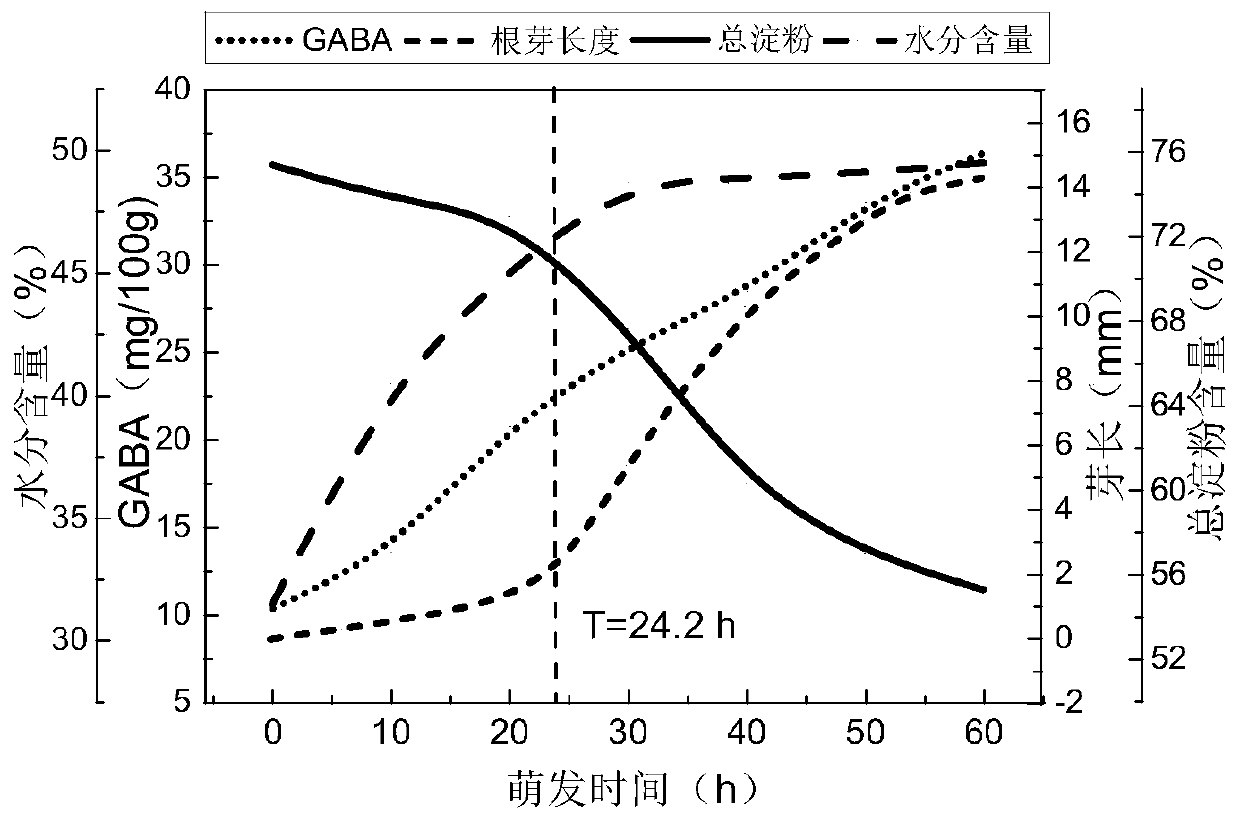

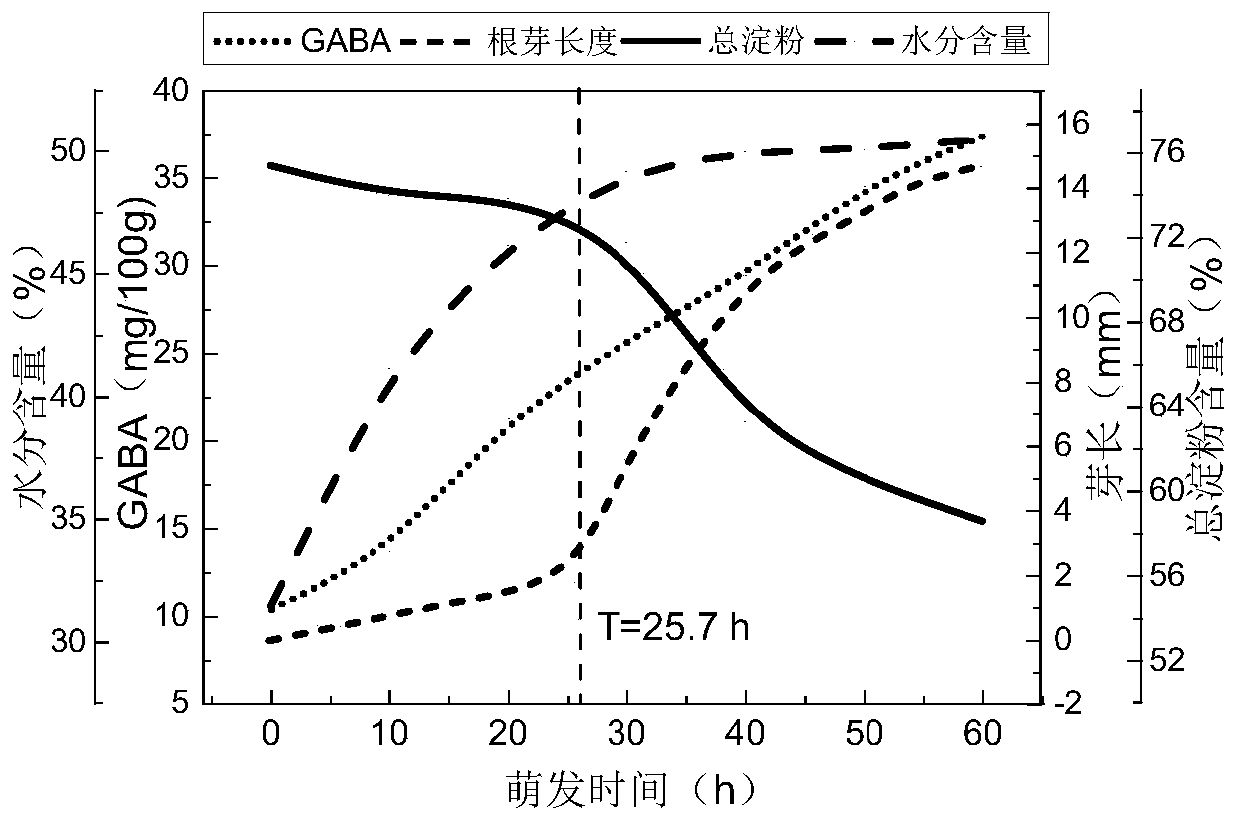

Image

Examples

Embodiment 1

[0048] A production method of mature highland barley powder, comprising the following steps:

[0049] (1) Take highland barley grains equivalent to 1 / 6 of the volume of the horizontal germination tank, remove impurities, moldy grains and broken grains therein, to ensure the purity of the grains and the fullness of the grains;

[0050] (2) Inject the highland barley grains of step (1) into a horizontal germination tank using a sodium hypochlorite solution with a concentration of 0.5% by mass, the ratio of the solution volume to the dry weight of the grains is controlled at 3.0mL / g, and after soaking for 30 minutes at 25°C Drain the sodium hypochlorite solution, inject enough sterile water into the germination tank and wash it 3 times;

[0051] (3) Maintain the ratio of the sterile water volume in the germination tank to the dry weight of the grain at 5.5mL / g, keep the temperature in the tank at 25°C, and soak for 4.0 hours;

[0052] (4) Exclude the soaking water in the germina...

Embodiment 2

[0058] A production method of mature highland barley powder, comprising the following steps:

[0059] (1) Take highland barley grains equivalent to 1 / 4 of the volume of the horizontal germination tank, remove impurities, moldy grains and broken grains therein, to ensure the purity of the grains and the fullness of the grains;

[0060] (2) Utilize the sodium hypochlorite solution of 1.0% mass percentage concentration to inject the highland barley grain of step (1) into the horizontal germination tank, the ratio of solution volume and grain dry weight is controlled at 2.0mL / g, after soaking at 28 ℃ for 25min Drain the sodium hypochlorite solution, inject enough sterile water into the germination tank and wash it 3 times;

[0061] (3) Maintain the ratio of the volume of sterile water in the germination tank to the dry weight of the grain at 6.0mL / g, keep the temperature in the tank at 28°C, and soak for 3.5 hours;

[0062] (4) Get rid of the soaking water in the germination tank...

Embodiment 3

[0068] A production method of mature highland barley powder, comprising the following steps:

[0069] (1) Take highland barley grains equivalent to 1 / 3 of the volume of the horizontal germination tank, remove impurities, moldy grains and broken grains therein, to ensure the purity of the grains and the fullness of the grains;

[0070] (2) Inject the highland barley grains of step (1) into a horizontal germination tank using a sodium hypochlorite solution with a mass percentage concentration of 1.5%, and control the ratio of the solution volume to the dry weight of the grains at 1.5mL / g, and soak them at 30°C for 20 minutes Drain the sodium hypochlorite solution, inject enough sterile water into the germination tank and wash it 4 times;

[0071] (3) Maintain the ratio of the volume of sterile water in the germination tank to the dry weight of the grain at 7.0mL / g, keep the temperature in the tank at 30°C, and soak for 3.0 hours;

[0072] (4) Get rid of the soaking water in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com