Modified metakaolin-based permeation-resistant and crack-resistant agent for concrete

A technology of metakaolin and concrete, which is applied in the field of modified metakaolin-based concrete anti-seepage cracking agent, which can solve the problems of reduced concrete work performance, mutual interference of water-reducing agents, and influence on normal construction, so as to slow down seepage and corrosion, reduce Porosity, effect of inhibiting intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

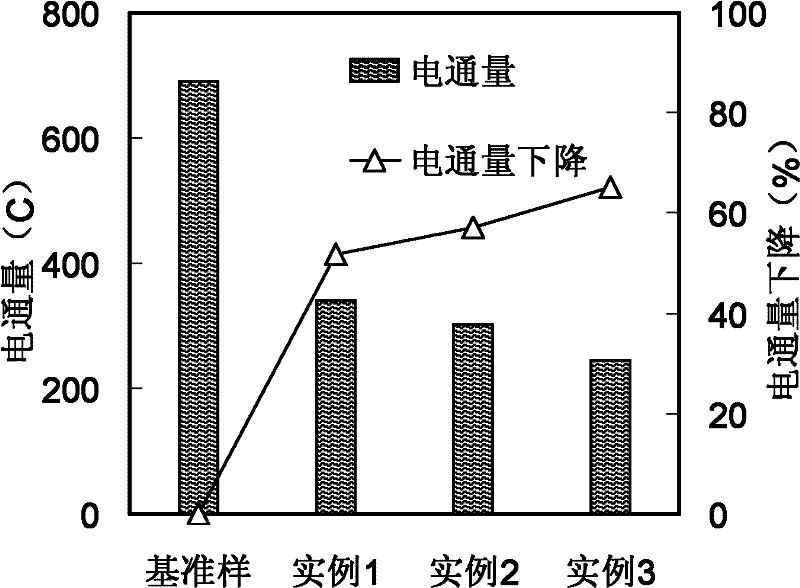

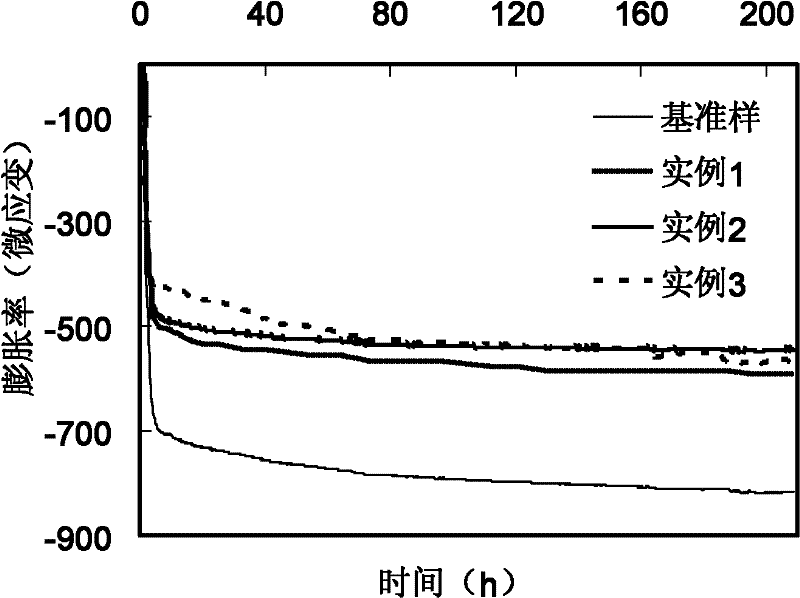

Embodiment 1-3

[0029] A modified metakaolin-based concrete anti-seepage cracking agent, which is prepared from modified metakaolin, ground limestone powder, ultra-fine fly ash, roasted hydrotalcite, ground quartz sand and solid silane powder, the raw materials The specific mass percentages are respectively 10%-75%, 5%-40%, 4%-40%, 1%-20%, 2%-20% and 0.2%-20%. The sum of the percentages of each component is 100%.

[0030] Based on C50 concrete, the modified metakaolin-based concrete anti-seepage and cracking agent is used to replace the cementitious material in the same amount to configure the concrete. The design composition ratio of the cementitious material in the concrete is shown in Table 1. The dosage of the benchmark concrete cementitious material is 435kg, and the water-cement ratio is 0.33.

[0031] Table 1 Concrete sample cementitious material composition ratio

[0032]

[0033] According to GB / T 50080-2002 "General Concrete Mixture Performance Test Method Standard" test the sl...

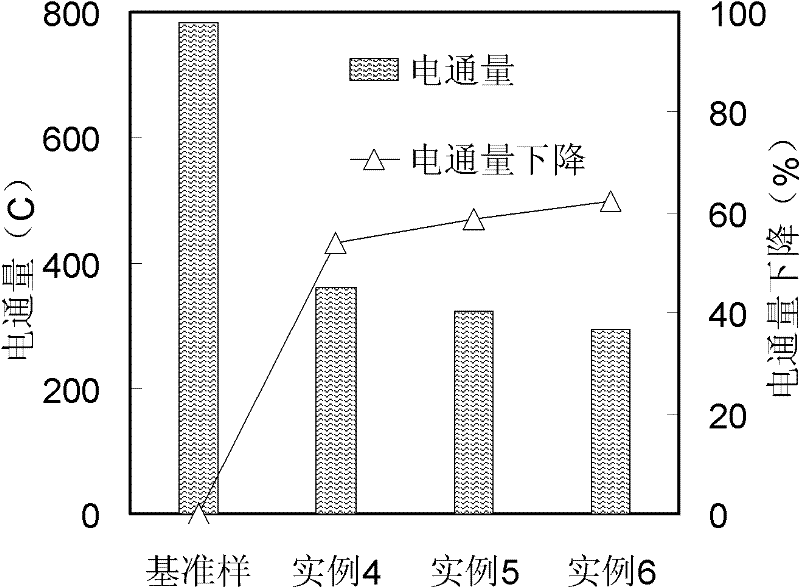

Embodiment 4-6

[0047] A modified metakaolin-based concrete anti-seepage cracking agent, which is prepared from modified metakaolin, ground limestone powder, ultra-fine fly ash, roasted hydrotalcite, ground quartz sand and solid silane powder, the raw materials The specific mass percentages are 210%-75%, 5%-40%, 4%-40%, 1%-20%, 2%-20% and 0.2%-20%, respectively. The sum of the percentages of each component is 100%.

[0048] Taking C40 marine concrete as the benchmark, the modified metakaolin-based concrete anti-seepage cracking agent is used to replace the cementitious material in the same amount to configure the concrete. The design composition ratio of the cementitious material in the concrete is shown in Table 4. The dosage of the benchmark concrete cementitious material is 423kg, and the water-cement ratio is 0.36.

[0049] Table 4 Concrete sample cementitious material composition ratio

[0050]

[0051] The fly ash described in Table 4 is a secondary fly ash with a fineness of 45 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com