BOPET film capable of being directly heat-sealed

A thin film, direct technology, applied in the field of polyester film, can solve the problems of undisclosed technology, achieve the effect of stable quality, small investment, and not easy to crystallize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

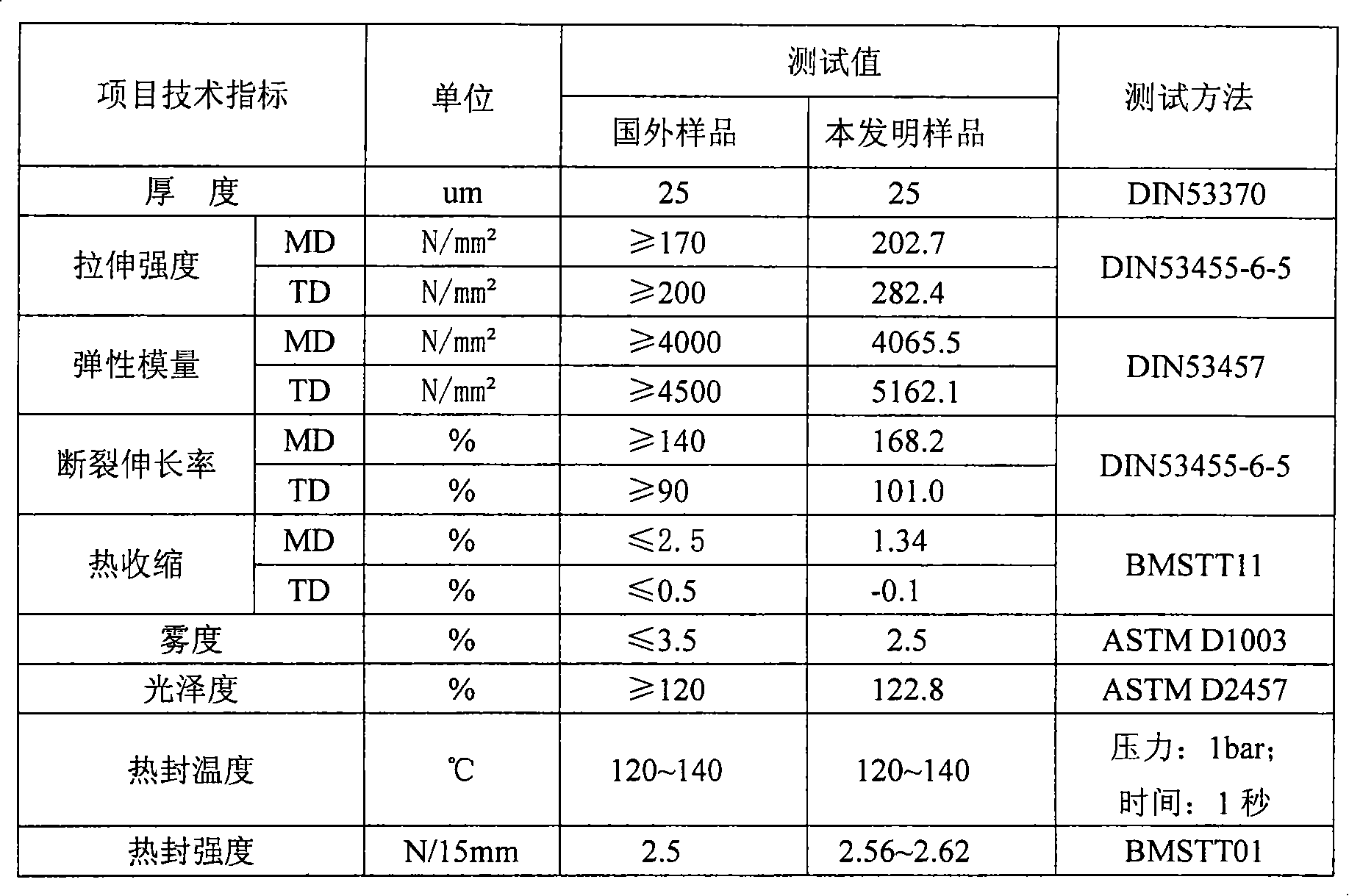

Examples

Embodiment 1

[0014] Material preparation: surface heat seal layer, copolyester PETG 85%, silicon masterbatch 15%, mixed evenly.

[0015] Core layer, PET light material 80%, PET re-granulation 20%, evenly mixed.

[0016] Bottom layer, silicon masterbatch 100%.

[0017] Core layer raw material crystallization and drying treatment: In order to avoid PET degradation during melt extrusion, the core layer raw material is crystallized and dried. The crystallization temperature is 150°C, the drying temperature is 160°C, and the drying time is not less than 6 hours.

[0018] The surface heat seal layer and the bottom layer use twin-screw vacuum pumps to remove moisture.

[0019] Melt extrusion: three-layer co-extrusion, in which the main extruder extrudes the core material, and the other two are twin-screw auxiliary extruders with vacuum exhaust function, which respectively extrude the surface heat-sealing layer and the bottom layer out. The extrusion temperature of the surface heat-sealing laye...

Embodiment 2

[0025] Material preparation: surface heat seal layer, copolyester PETG 90%, silicon masterbatch 10%, mixed evenly.

[0026] Core layer, PET optical material 85%, PET re-granulation 15%, evenly mixed.

[0027] Bottom layer, silicon masterbatch 100%.

[0028] All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com