Modified polyvinylidene fluoride material used for solar cell protective films and preparation method thereof

A technology of solar cells and polyvinylidene fluoride, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as hindering domestic fluoroplastic films, and achieve the effects of improving processing plasticity, mitigating impact damage, and good value for money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

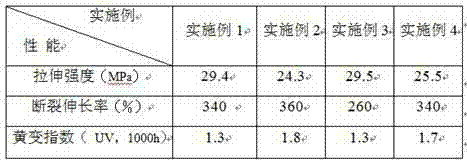

Examples

preparation example Construction

[0019] The invention provides a modified polyvinylidene fluoride material used for solar cell protective films and a preparation method thereof. By modifying PVDF, the PVDF material is blended with HDPE and POE to improve the surface free energy of the PVDF film. Improve its bonding strength with E / VAC, PET substrates.

[0020] Modified polyvinylidene fluoride material for solar cell protective film, the composition weight ratio is: polyvinylidene chloride (PVDF) 55~70%, polyethylene (HDPE) 10~20%, polyethylene grafted maleic anhydride 3 ~6%, ethylene - Octene copolymer (POE) 10~20%, antioxidant 0.3~0.6%, lubricant 0.2~0.5%.

[0021] The preferred formula is: polyvinylidene chloride 65%, polyethylene 14.3%, polyethylene grafted maleic anhydride 5%, ethylene-octene copolymer 15%, antioxidant 0.4%, lubricant 0.3%.

[0022] Among them, the melting point of polyvinylidene chloride is 145°C, and the thermal decomposition temperature is above 320°C; the grade of polyethylene is po...

Embodiment 1

[0028] First, add 65 parts of polyvinylidene chloride, 14.3 parts of polyethylene, 5 parts of polyethylene grafted maleic anhydride, 15 parts of ethylene-octene copolymer, 0.4 parts of antioxidant, and 0.3 parts of ethylene bisstearamide into the high-speed Mix it evenly in the mixing barrel; then, add the twin-screw extruder for mixing, and the temperature of each section of the twin-screw is respectively: T 1 =150℃, T 2 =170°C, T 3 =170°C, T 4 =180°C, T 5 =190°C, T 6 =200℃, twin-screw extruder speed r=350r.min -1 , and finally, extrude, cool, and pelletize to obtain the modified polyvinylidene fluoride material used for the protective film of solar cells.

Embodiment 2

[0030] First, add 55 parts of polyvinylidene chloride, 19.9 parts of polyethylene, 4 parts of polyethylene grafted maleic anhydride, 20 parts of ethylene-octene copolymer, 0.6 parts of antioxidant, and 0.5 parts of ethylene bisstearamide into the high-speed Mix it evenly in the mixing barrel; then, add the twin-screw extruder for mixing, and the temperature of each section of the twin-screw is respectively: T 1 =150℃, T 2 =160°C, T 3 =170°C, T 4 =180°C, T 5 =190°C, T 6 =200℃, twin-screw extruder speed r=340r.min -1 , and finally, extrude, cool, and pelletize to obtain the modified polyvinylidene fluoride material used for the protective film of solar cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com