Electrically controlled solid propellant and preparation method thereof

A solid propellant, electronically controlled technology, used in offensive equipment, compressed gas generation, non-explosive/non-thermal composition, etc., can solve the impact of the measured density and mechanical properties of the propellant, reduce effectiveness and multiple ignition and flameout , affecting the uniformity of the propellant, etc., to save the preparation time, prevent the generation of gel clusters, and improve the uniformity and fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The embodiment of the present invention also provides a method for preparing an electrically controlled solid propellant, comprising the following steps:

[0059] Step 1): Weigh the raw materials according to the formula provided in the above-mentioned raw material formula embodiment;

[0060] For the description and effect of the raw materials, please refer to the above-mentioned formula examples, and will not repeat them here; among them, it is preferable to prepare the mass Hydroxylamine nitrate aqueous solution with a concentration of 5-10%;

[0061] Step 2): adding the weighed binder, secondary oxidizing agent, crosslinking agent and functional auxiliary agent into the aqueous solution of hydroxylamine nitrate to completely dissolve to obtain a uniform slurry;

[0062] Step 3): Concentrating and dewatering the syrup obtained in step 2);

[0063] Step 4): Pour the concentrated syrup into a mold, freeze and solidify to obtain an electronically controlled solid prop...

example 1

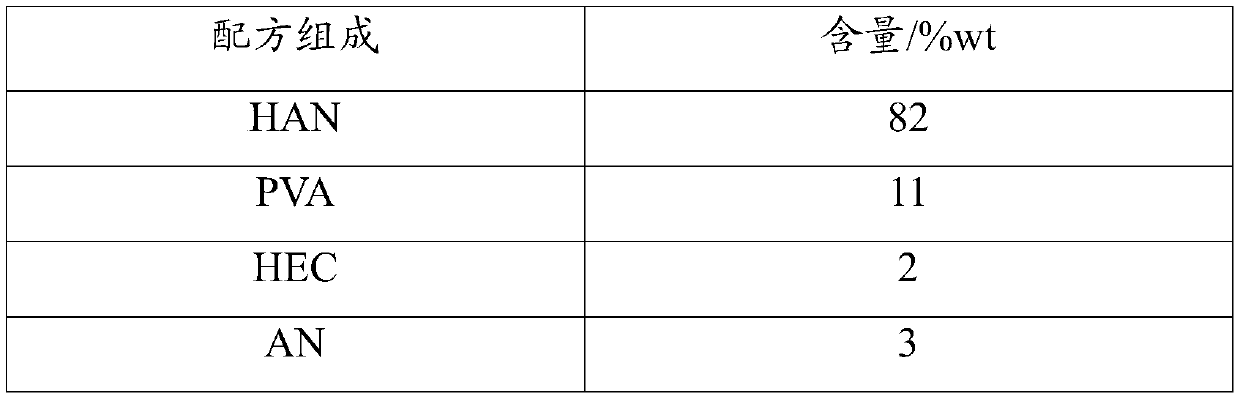

[0069] Take the raw material by weighing the formula in Table 1;

[0070] The weighed binder polyvinyl alcohol, secondary oxidant ammonium nitrate, crosslinking agent nano silicon dioxide, buffer stabilizer ammonium dihydrogen phosphate, chelating stabilizer 2,2-bipyridine, fuel additive cyclodextrin, heat The stabilizer pentaaminotetrazole was added to the HAN aqueous solution with a mass concentration of 5%, heated to 80°C, and stirred until it was completely dissolved; the heating device was turned off, and the solution was cooled to 50°C, then concentrated and dewatered by vacuum stirring until The water content in the receiving bottle accounts for 94% of the total mass of the HAN aqueous solution, and the air bubbles in the slurry are removed by using a vacuum environment. Pour the concentrated slurry into a mold, freeze at -40°C for 24 hours, thaw at room temperature, and cycle 3 times to prepare an electronically controlled solid propellant with good uniformity.

[007...

example 2

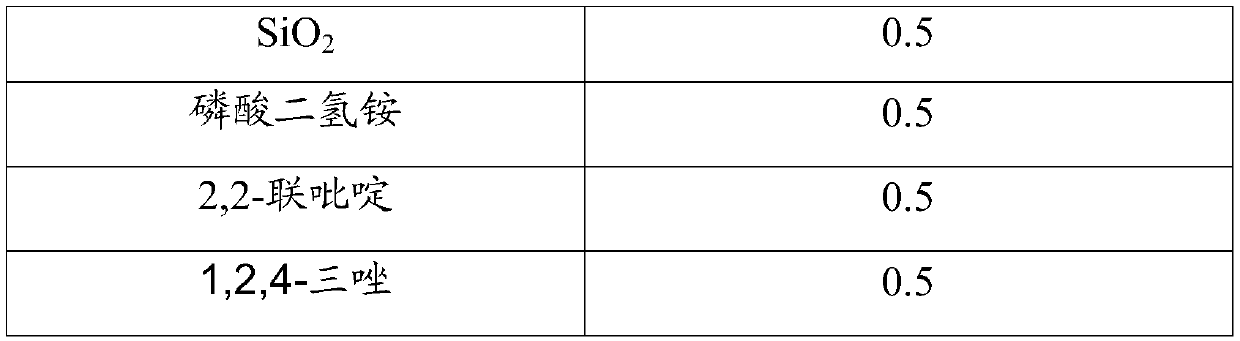

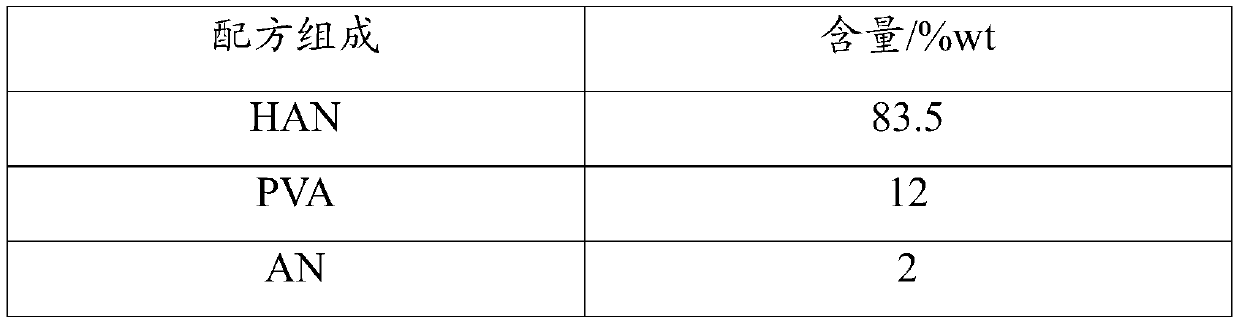

[0075] Take by weighing raw material according to table 2 formula;

[0076] The weighed binder polyvinyl alcohol, secondary oxidant sodium nitrate, crosslinking agent tetraethyl orthosilicate, buffer stabilizer ammonium dihydrogen phosphate, chelating stabilizer edetate disodium, heat stabilizer five Add aminotetrazole together to 5% HAN aqueous solution, heat to 80°C, stir until completely dissolved; turn off the heating device, wait for the solution temperature to cool to 60°C, and vacuum stir to concentrate and remove water until it reaches the receiving bottle The water content accounts for 94% of the total mass of the HAN aqueous solution, and the air bubbles in the slurry are removed by using a vacuum environment. Pour the concentrated slurry into a mold, freeze at -30°C for 15 hours, thaw at room temperature, and cycle 4 times to prepare an electronically controlled solid propellant with good uniformity.

[0077] Table 2 Example 2 raw material formula table

[0078] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com