Heat-sealable high-barrier packaging film

A packaging film and high-barrier technology, applied in the field of heat-sealable high-barrier packaging film, can solve the problems of high crystallinity, high melting point, and limited use of packaging materials, so as to improve surface smoothness, reduce costs, and improve barrier self-extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

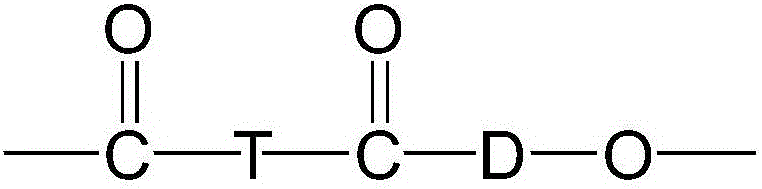

Method used

Image

Examples

Embodiment Construction

[0025] Heat-sealable high barrier packaging film processing technology:

[0026] The PET slices and inorganic particles, PETG and PET blended slices, the two mixed thermal resin materials are dried by the blower dryer respectively, and then three corresponding twin-screw extruders are respectively used to pass through the three-layer co-extrusion die. Extrusion, followed by filtration, casting, longitudinal stretching, online coating, transverse stretching, traction winding, and slitting to obtain a heat-sealable high-barrier packaging film.

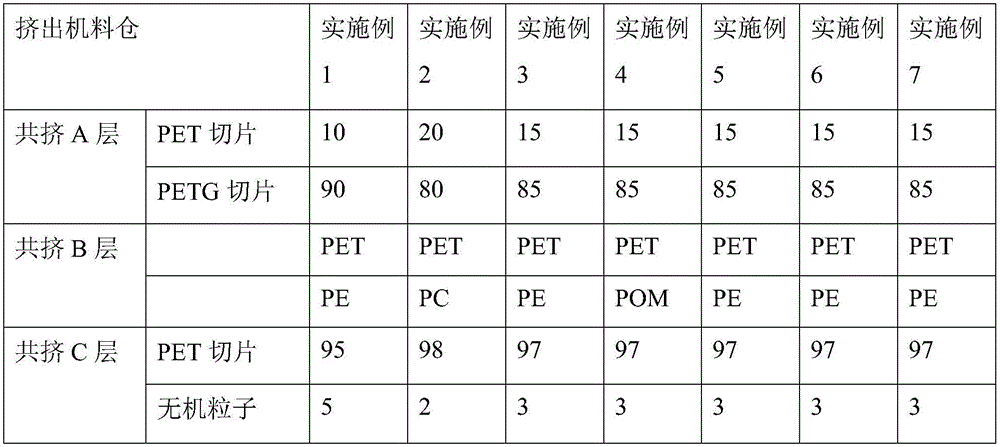

[0027] The composition of each component of Table 1 Embodiment 1~7

[0028]

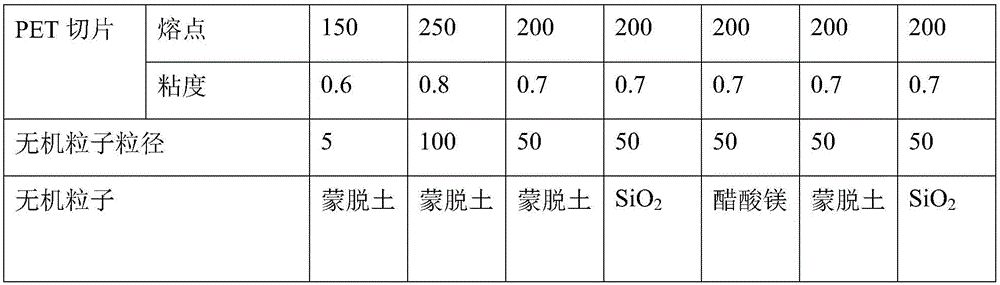

[0029]

[0030] As shown in Table 2, the above embodiments were tested, the test content is as follows, and the test results are shown in Table 2.

[0031] 1. Tensile test (tensile strength)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com