Matte super-hard weatherproof finishing material

A technology of ultra-hard weather-resistant and varnished materials, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor ground wetting effect, shortened service life of the floor, and easy to be stained with dust , to achieve good anti-shrinkage performance, long storage period, and appropriate volatilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a matte superhard weather-resistant finish material, comprising the steps of:

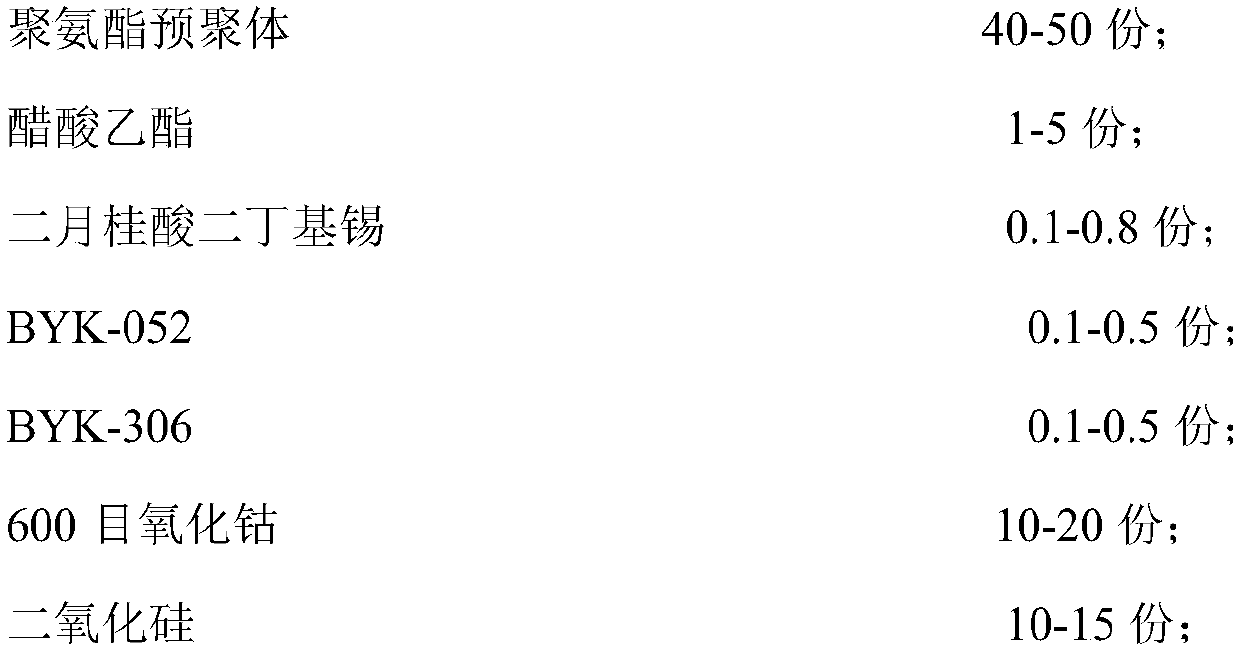

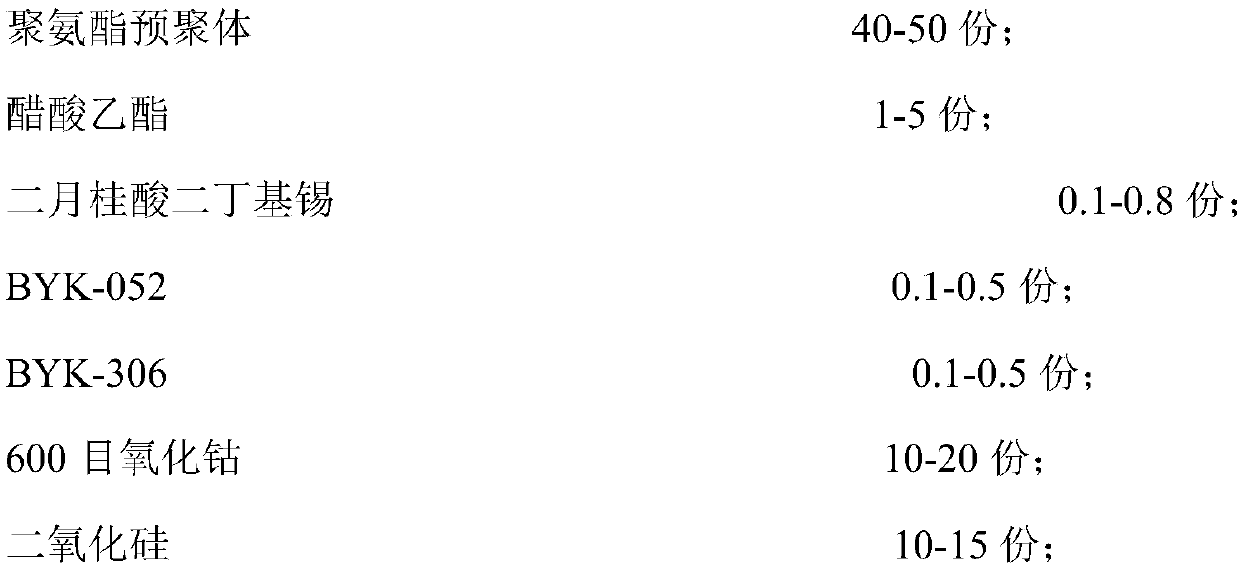

[0030] S1: Preparation of component A: (1) Mix the polyurethane prepolymer and ethyl acetate in the above parts by weight and stir evenly. The stirring speed is 2500r / min, the temperature is 80°C, and the stirring time is 30min;: (2 ) under stirring at 3000 rpm, slowly add dibutyltin dilaurate, BYK-052, 600 mesh cobalt oxide and silicon dioxide nanopowder in the above parts by weight, fully stir and adjust evenly, the stirring time is 30min, and the temperature is 80°C; (3) Finally, add BYK-306 in the above parts by weight in step (2), stir evenly, the stirring speed is 3000 rpm, the stirring time is 15min, and the temperature is 80°C;

[0031] S2: Preparation of component B: Stir the hydroxyl-containing silicone resin and acrylic resin in the above parts by weight at a medium speed of 1800 rpm for 30 minutes, and the stirring temperature is 80 minutes;

[0032] S3: Mix...

Embodiment 2

[0039] A method for preparing a matte superhard weather-resistant finish material, comprising the steps of:

[0040] S1: Preparation of component A: (1) Mix the polyurethane prepolymer and ethyl acetate in the above parts by weight and stir evenly. The stirring speed is 2300r / min, the temperature is 75°C, and the stirring time is 30min;: (2 ) under stirring at 2800 rpm, slowly add dibutyltin dilaurate, BYK-052, 600 mesh cobalt oxide and silicon dioxide nanopowder in the above parts by weight, fully stir and adjust evenly, the stirring time is 30min, and the temperature is 75°C; (3) Finally, in step (2), add the BYK-306 in the above parts by weight, stir evenly, the stirring speed is 3000 rpm, the stirring time is 10min, and the temperature is 75°C;

[0041] S2: Preparation of component B: Stir the hydroxyl-containing silicone resin and acrylic resin in the above parts by weight at a medium speed of 1600 rpm for 25 minutes, and the stirring temperature is 75 minutes;

[0042] ...

Embodiment 3

[0049] A method for preparing a matte superhard weather-resistant finish material, comprising the steps of:

[0050] S1: Preparation of component A: (1) Mix the polyurethane prepolymer and ethyl acetate in the above parts by weight and stir evenly. The stirring speed is 2000r / min, the temperature is 70°C, and the stirring time is 30min;: (2 ) under stirring at 2500 rpm, slowly add dibutyltin dilaurate, BYK-052, 600 mesh cobalt oxide and silicon dioxide nanopowder in the above parts by weight, fully stir and adjust evenly, the stirring time is 30min, and the temperature is 70°C; (3) Finally, in step (2), add BYK-306 in the above parts by weight, stir evenly, the stirring speed is 2500 rpm, the stirring time is 10min, and the temperature is 70°C;

[0051] S2: Preparation of component B: Stir the hydroxyl-containing silicone resin and acrylic resin in the above parts by weight at a medium speed of 1500 rpm for 20 minutes, and the stirring temperature is 70 minutes;

[0052] S3: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| UV absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com