Patents

Literature

36results about How to "High-NCO content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

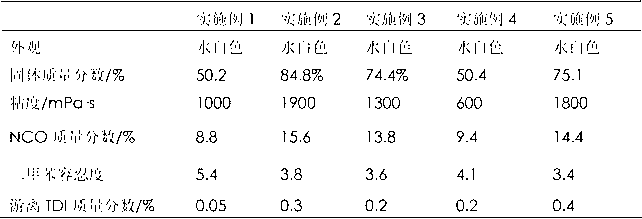

Preparation method of polyurethane prepolymer with low free isocyanate monomer

The invention discloses a preparation method of polyurethane prepolymer with low free isocyanate monomer. The preparation method comprises the following steps of: forming into mixed alcohol by trihydric alcohol and dihydric alcohol under the temperature of 120-150DEG C, and carrying out vacuum dehydration; putting isocyanate monomer and ester solvents into a reactor to keep the temperature at 30-70DEG C, and dropwise adding the mixed alcohol into the reactor; after dropwise adding, continuously reacting for 3-6h under the temperature of 40-70DEG C under stirring, and discharging in a cooling way to obtain polyurethane prepolymer; and separating the obtained polyurethane prepolymer, and adjusting the solid content of polyurethane prepolymer solid and the content of free isocyanate monomer in the separated heavy components by diluted solvent. According to the preparation method, the real continuous production can be realized, all the recovered solvent and isocyanate monomer can be recycled, the zero emission can be realized, and the real clean production can be realized; and the product has the characteristics of being low in viscosity, high and adjustable in NCO value content, low in the content of the free isocyanate monomer, high in solid content, good in compatibility, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

Polyurethane adhesive, preparation method thereof and heat-conducting adhesive tape

InactiveCN106978128AEvenly dispersedImprove thermal conductivityNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterPolyurethane adhesive

The invention discloses a preparation method of a polyurethane adhesive. The preparation method comprises the following steps: (1) adding polyester polyol into a reaction kettle, and carrying out vacuum dehydration; (2) coupling graphene oxide with a silane coupling agent so as to obtain processed graphene oxide, adding processed graphene oxide and a combined solvent into the reaction kettle of the step (1), and carrying out ultrasonic treatment for 2-8 hours; (3) adding isocyanate, a catalyst and a chain extender into the reaction kettle of the step (2), heating to 80-90 DEG C, and reacting for 2-7 hours; and (4) carrying out vacuum distillation on substances in the reaction kettle of the step (3) at 80-90 DEG C, cooling, and discharging, so as to obtain the polyurethane adhesive. The polyurethane adhesive prepared by virtue of the preparation method is high in heat conductivity coefficient and peel strength.

Owner:东莞市普力达光学材料科技有限公司

Water curable polyurethane compositions with improved viscosity characteristics

InactiveUS7148287B2Favorable viscosity and viscosity stability characteristicPreserving desired hardness characteristicsPolyurea/polyurethane coatingsScavengerPolyol

Compositions incorporating water-curable urethane constituent(s) are formulated with favorable viscosity and viscosity stability characteristics, while at the same time, preserving desired hardness characteristics. The present invention is particularly useful in applications in which water-curable compositions include NCO-functional resins having relatively high NCO content and / or incorporate MDI-based constituents. Preferred modes of practicing the invention include implementing one or more formulation strategies to help retain hardness while preserving good viscosity characteristics. These preferred strategies involve (i) balancing scavenger, polyisocyanate and polyfunctional polyol content of the compositions or resins thereof, as the case may be, (ii) formulating an NCO-functional resin with chain extender constituent(s) to enhance viscosity stability, (iii) formulating with one or more plasticizers that enhance viscosity performance, and (iv) combinations of two or more of these strategies.

Owner:GUPTA LAXMI C

Water curable polyurethane compositions with improved viscosity characteristics

InactiveUS20050027093A1Reduce foamingFavorable viscosity and viscosity stability characteristicPolyurea/polyurethane coatingsScavengerPolyol

Compositions incorporating water-curable urethane constituent(s) are formulated with favorable viscosity and viscosity stability characteristics, while at the same time, preserving desired hardness characteristics. The present invention is particularly useful in applications in which water-curable compositions include NCO-functional resins having relatively high NCO content and / or incorporate MDI-based constituents. Preferred modes of practicing the invention include implementing one or more formulation strategies to help retain hardness while preserving good viscosity characteristics. These preferred strategies involve (i) balancing scavenger, polyisocyanate and polyfunctional polyol content of the compositions or resins thereof, as the case may be, (ii) formulating an NCO-functional resin with chain extender constituent(s) to enhance viscosity stability, (iii) formulating with one or more plasticizers that enhance viscosity performance, and (iv) combinations of two or more of these strategies.

Owner:GUPTA LAXMI C

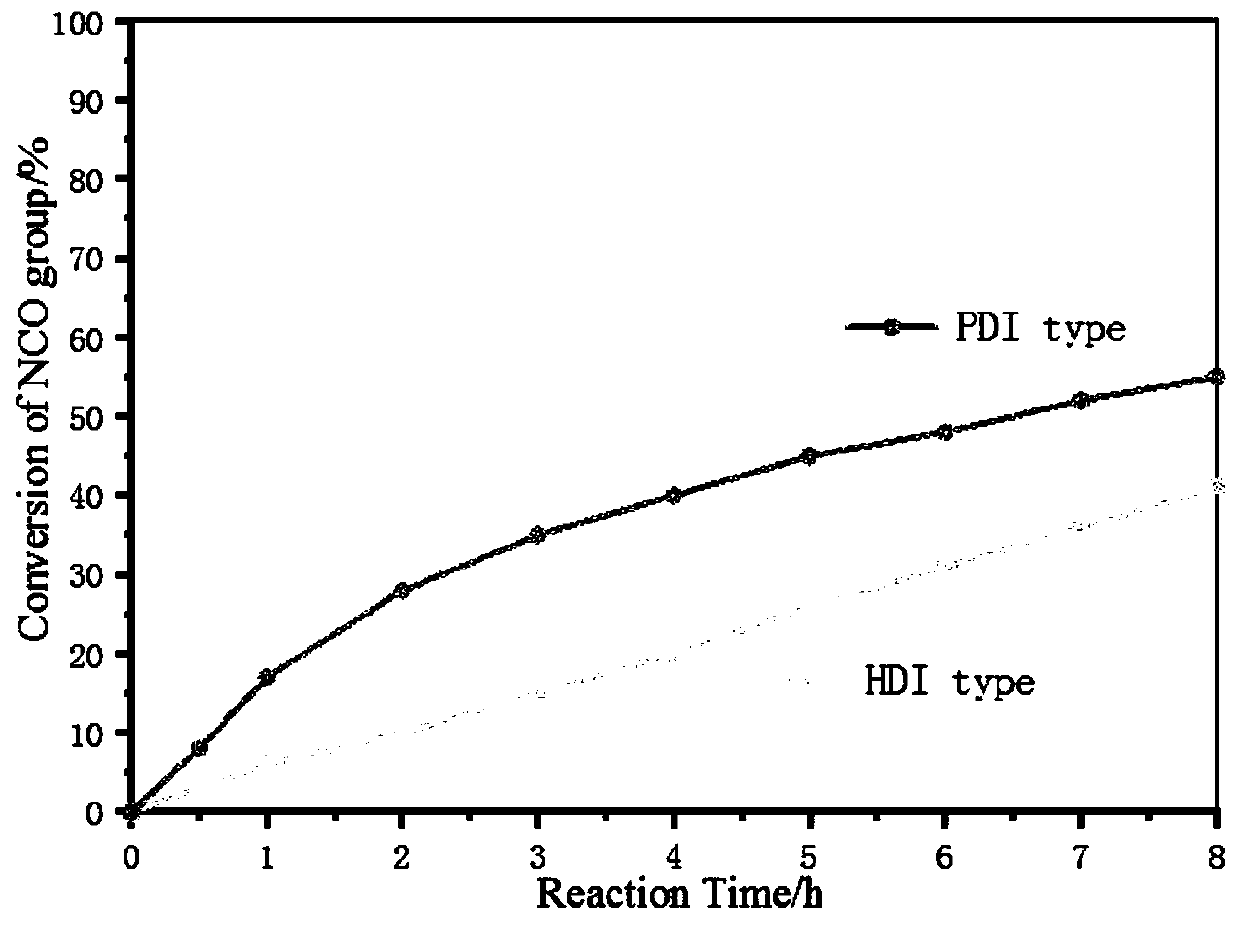

Method of synthesizing polyurethane curing agent by multi-batch charging manner and product thereof

ActiveCN104262578ASimple operation processReduce manufacturing costCarbamic acid derivatives preparationOrganic compound preparationAlcoholRoom temperature

The invention belongs to the field of polyurethane curing agents and discloses a method of synthesizing a polyurethane curing agent by a multi-batch charging manner and a product thereof. The method includes following steps of: mixing a small molecule alcohol with single hydroxy and an isocyanate monomer, reacting at 20-60 DEG C for 1-2 h to obtain a polyurethane prepolymer, mixing a Mannich base catalyst and a polar solvent, stirring, heating to 30-100 DEG C, preheating for 20-40 min, dividing the polyurethane prepolymer into equal parts according to mass, adding the equal polyurethane prepolymer parts into a mixed solvent in batch, adding a polymerization inhibitor to terminate the reaction after the addition is finished, and adding a small molecule alcohol for modification to obtain the product that is the polyurethane curing agent. In the polyurethane curing agent, the solid content is 50+ / -2%, the NCO group content is 7.0-8.0%, and the percentage of free TDI is not more than 0.5%. The polyurethane curing agent has advantages of light color, narrow molecular weight distribution and capability of rapidly curing at room temperature.

Owner:SOUTH CHINA UNIV OF TECH

Water curable polyurethane compositions and uses thereof

Increased health, safety, and environmental awareness motivated the development of new and improved water curing technology for formulating, manufacturing, and using water curable compositions (also referred to in the art as water induced urethanes). The present invention is based, at least in part, upon the concept of formulating NCO functional resins used in water curable compositions from one or more polyisocyanate constituents that comprise at least one sterically hindered isomer of diphenyl methane diisocyanate (MDI). These isomers have a combination of exceptionally low vapor pressure and suitable moisture reactivity that lead to numerous advantages. Due to their low volatility, these isomers may be substituted for all or a portion of the TDI content of a conventional water induced urethane formulation. Particularly preferred embodiments eliminate any TDI, have 100% solids, are solvent free, and are characterized by essentially zero VOC emissions with respect to isocyanate. The compositions are substantially more environmentally friendly than conventional formulations.

Owner:GUPTA LAXMI C

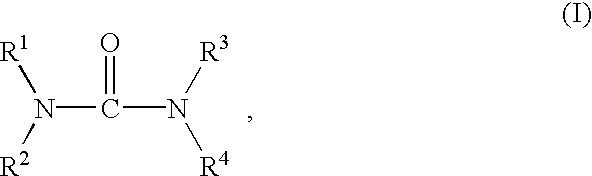

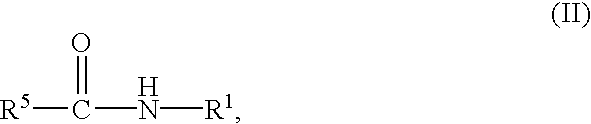

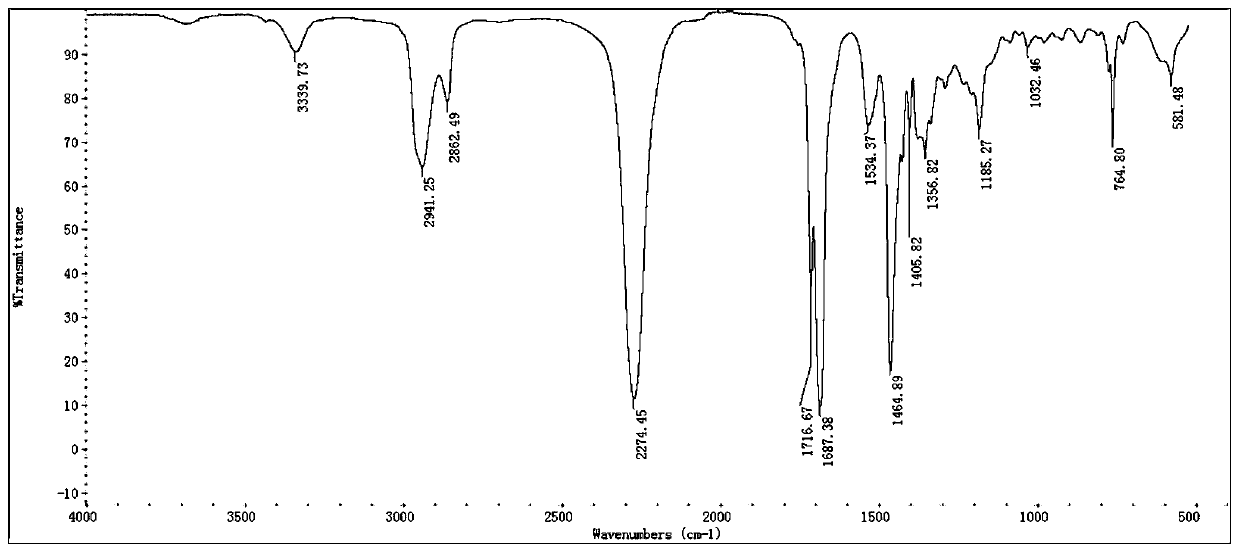

Preparation of biuret-containing polyisocyanates

InactiveUS7022874B2Easy to disassembleIncrease resistanceUrea derivatives preparationIsocyanic acid derivatives preparationArylAlcohol

A process for the preparation of polyisocyanates which contain one or more biuret groups, by reactinga) an aliphatic or cycloaliphatic isocyanate containing two or more isocyanate groups (isocyanate a) withb) a tertiary alcohol or a mixture of water and a tertiary alcohol (biuretizing agent b)at from 100 to 250° C., which comprises carrying out the reaction in the presencec) of a stabilizer (c) which constitutes a catalytic amount of urea, ammonia, biuret, a urea derivative of the formula I in which R1, R2, R3 and R4 are hydrogen, C1 to C10 alkyl or C5 to C10 aryl, ora carboxamide of the formula II in which R5 is C1 to C12 alkyl which is unsubstituted or in which 1, 2 or 3 hydrogen atoms are replaced by a radical

Owner:BASF AG

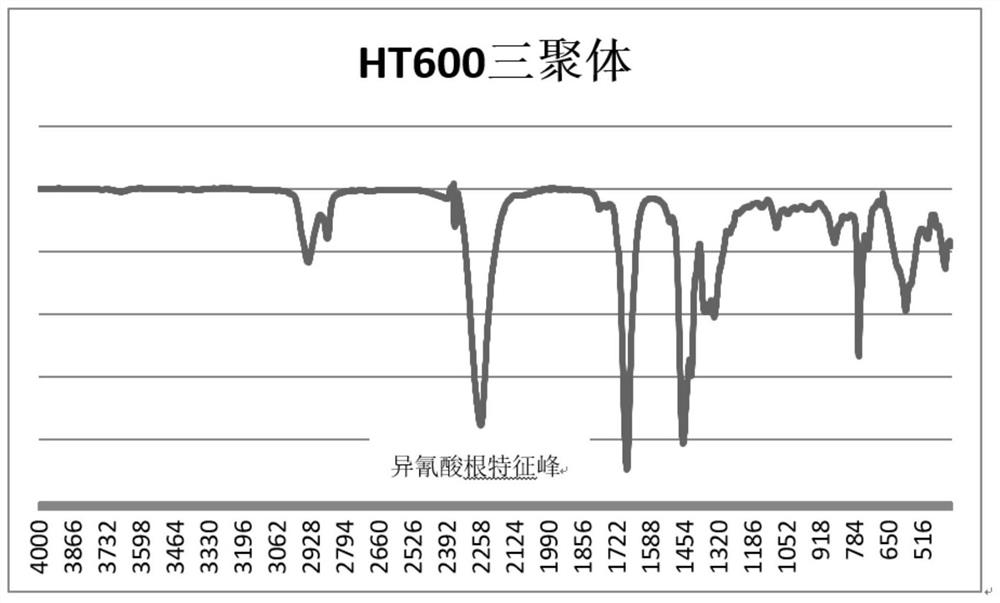

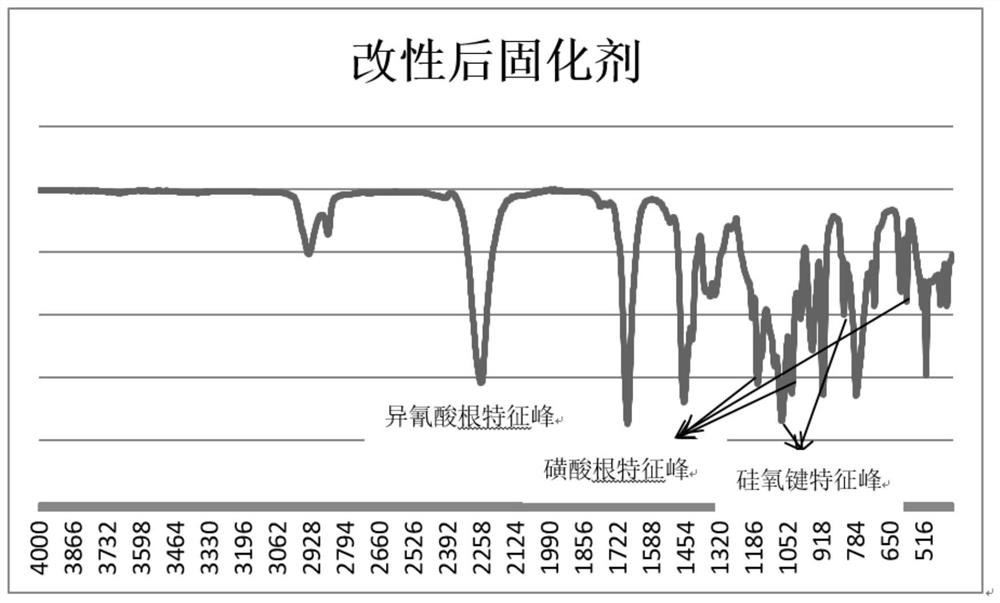

Ionic waterborne curing agent based on bio-based pentamethylene diisocyanate and preparation method thereof

The invention relates to the technical field of curing agents, specifically to an ionic waterborne curing agent based on bio-based pentamethylene diisocyanate and a preparation method thereof. The preparation method for the ionic waterborne curing agent based on the bio-based pentamethylene diisocyanate provided by the invention comprises the following steps: mixing an impurity-removed bio-based pentamethylene diisocyanate trimer, a sulfamic acid substance and organic amine, then carrying out heating to 60 DEG C to 110 DEG C under the protection of nitrogen, carrying out a reaction for 3 to 7hours, and when a product is transparent, carrying out cooling to 25 DEG C to 40 DEG C. The preparation method provided by the invention has the following advantages: the process of synthesis is simple; the flow of operation is easy to be mastered; the raw material namely the bio-based pentamethylene diisocyanate trimer has a clean source and is free of pollution to the environment; and through addition of a small amount of sulfonate and the organic amine, the ionic waterborne curing agent with a solid content of 100%, an NCO content of up to 22.3%, low viscosity and rapid curing rate can be obtained.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Method for preparing polyurethane-modified organosilicon double-component room-curing elastomer adhesive

ActiveCN105018015AEasy to operateShorten the production cycleNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElastomerAdhesive

The invention discloses a method for preparing a polyurethane-modified organosilicon double-component room-curing elastomer adhesive, which comprises the following steps: (1) uniformly mixing hydroxypropyl-terminated silicone oil and glycerol, and dehydrating to obtain a hydroxyl-terminated (-OH) component; (2) reacting aromatic polyisocyanate, the hydroxyl-terminated (-OH) component and dibutyltin dilaurate to obtain a component A; (3) adding vapor-phase silica white, carbon black and talcum powder into the container filled with hydroxy silicone oil and dihydroxy polysiloxane, adding a catalyst, adding 3-aminopropyl triethoxy silane, finally adding a defoaming agent, uniformly mixing, and drying to obtain a component B; and (4) uniformly mixing the component A and component B in a mass ratio of 12:(23.5-24), and curing at room temperature for 4-5 hours. The elastomer adhesive prepared by the method has the advantages of favorable tear resistance, excellent high / low temperature resistance and excellent binding property. The preparation method is easy to operate and accessible in raw materials, and lowers the preparation cost.

Owner:道一高分子聚合物(宁波)有限公司

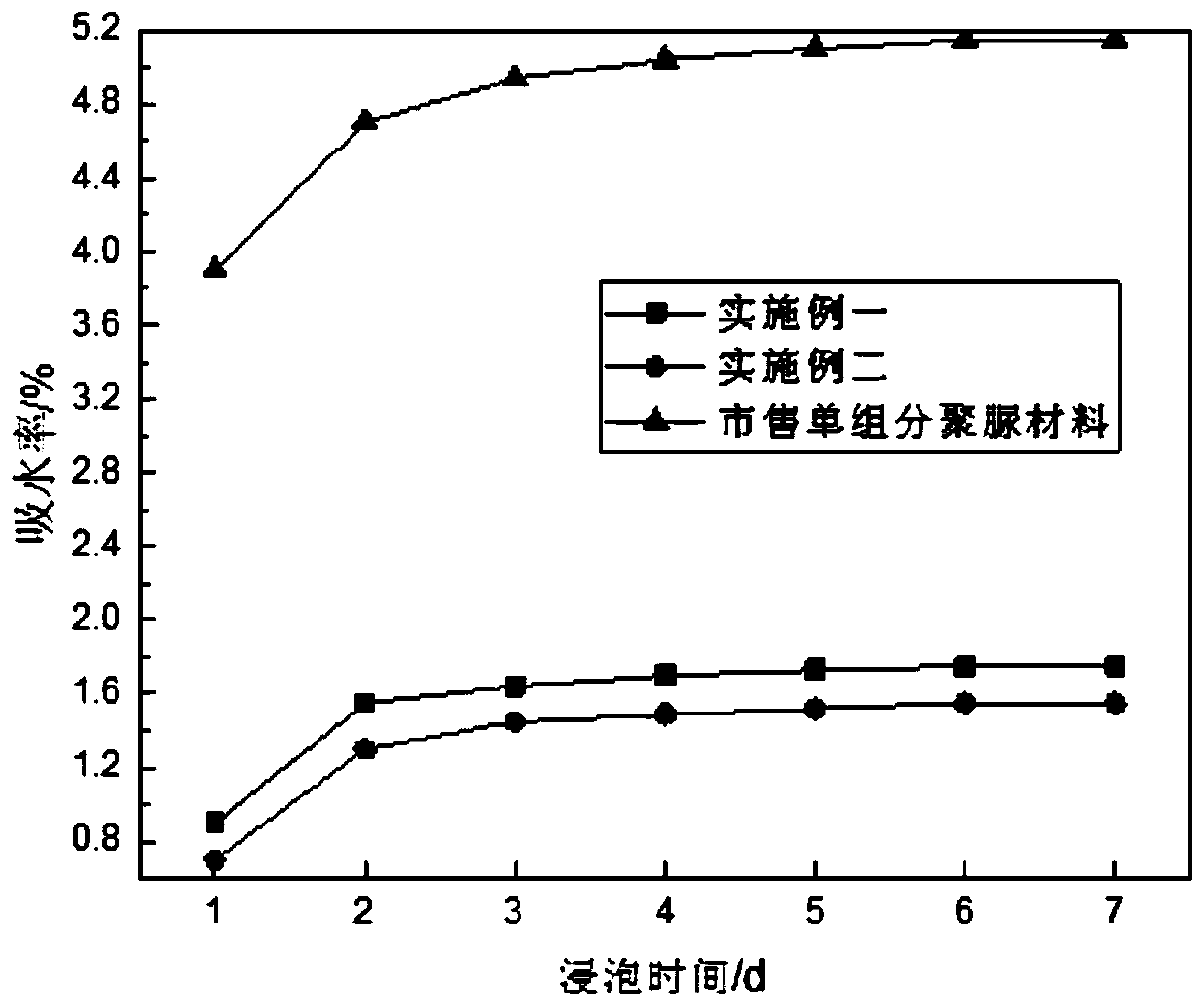

Environment-friendly high urea linkage fast curing single component polyurea material and preparation method thereof

The invention provides an environment-friendly high urea linkage fast curing single component polyurea material. The environment-friendly high urea linkage fast curing single component polyurea material is prepared from the following components in parts: 80-140 parts of blocked isocyanate prepolymer, 5.5-7 parts of a polyurea liquid filler, 30-40 parts of amine-terminated polyether, 5-10 parts ofa terminated amino chain extender, 4-6 parts of a solid filler and 1-2 parts of an auxiliary agent. According to the environment-friendly high urea linkage fast curing single component polyurea material, the polyurea liquid filler can improve the urea linkage content of a system, and the solvent-free solid content is 100%, thereby ensuring high durability used in water environment. The environment-friendly high urea linkage fast curing single component polyurea material has good mechanical properties, environmental protection is achieved, hydrolysis resistance is achieved, and the material canbe thick coated into a film at a time, cured fast, and is suitable for quick repair needs of water conservancy projects, and the like. In addition, the environment-friendly high urea linkage fast curing single component polyurea material has a simple preparation method and is suitable for industrial production.

Owner:李泽阳

Enclosed type polyurethane curing agent emulsion and preparation method and applications thereof

ActiveCN109897160AEasy to useGood water resistancePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPrepolymerIsocyanate

The invention discloses an enclosed type polyurethane curing agent emulsion and a preparation method and applications thereof. The enclosed type polyurethane curing agent emulsion is prepared by the following steps: (a) preparing polyisocyanate prepolymer containing a sulfonic acid group; (b) preparing enclosed type polyisocyanate prepolymer; and (c) preparing enclosed type polyurethane curing agent emulsion. The invention also discloses applications of the enclosed type polyurethane curing agent emulsion. The enclosed type polyurethane curing agent emulsion exists in a form of aqueous emulsion and can be individually stored for a long term. The emulsion does not contain any organic solvent, has a high solid content and a high NCO content, can be directly diluted by adding water, and can be stored for a long term after being mixed with aqueous resin containing active hydrogen. The prepared aqueous baking finish and aqueous high temperature glue are convenient to use; and the prepared products have a good waterproof property and high strength.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

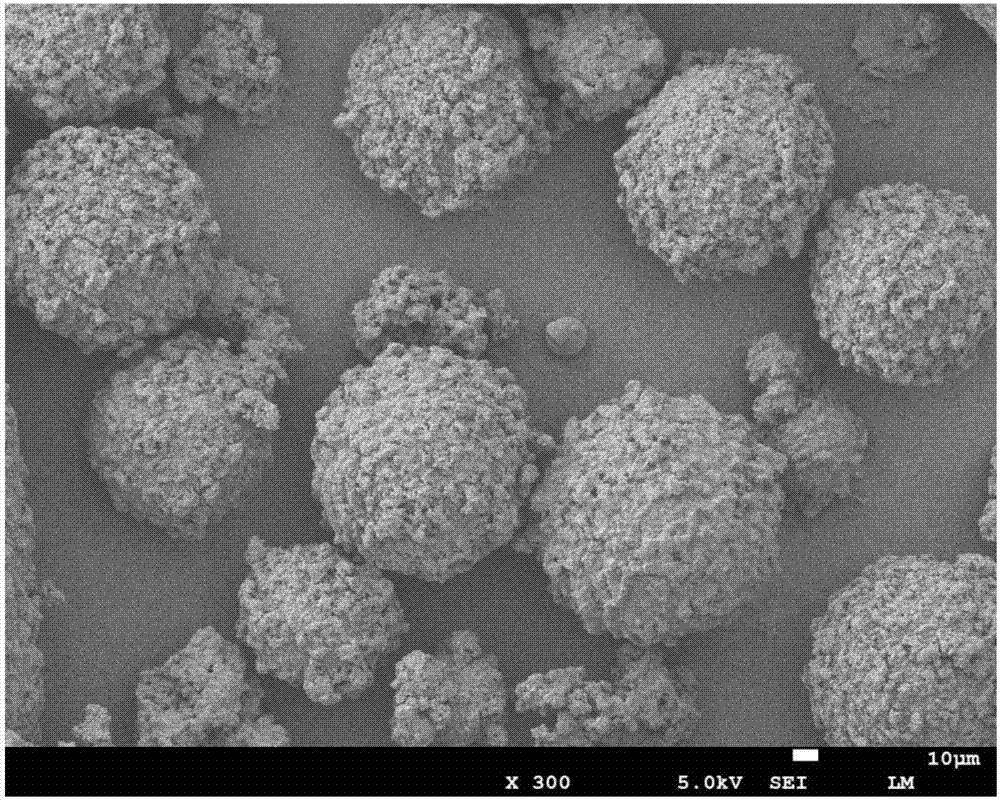

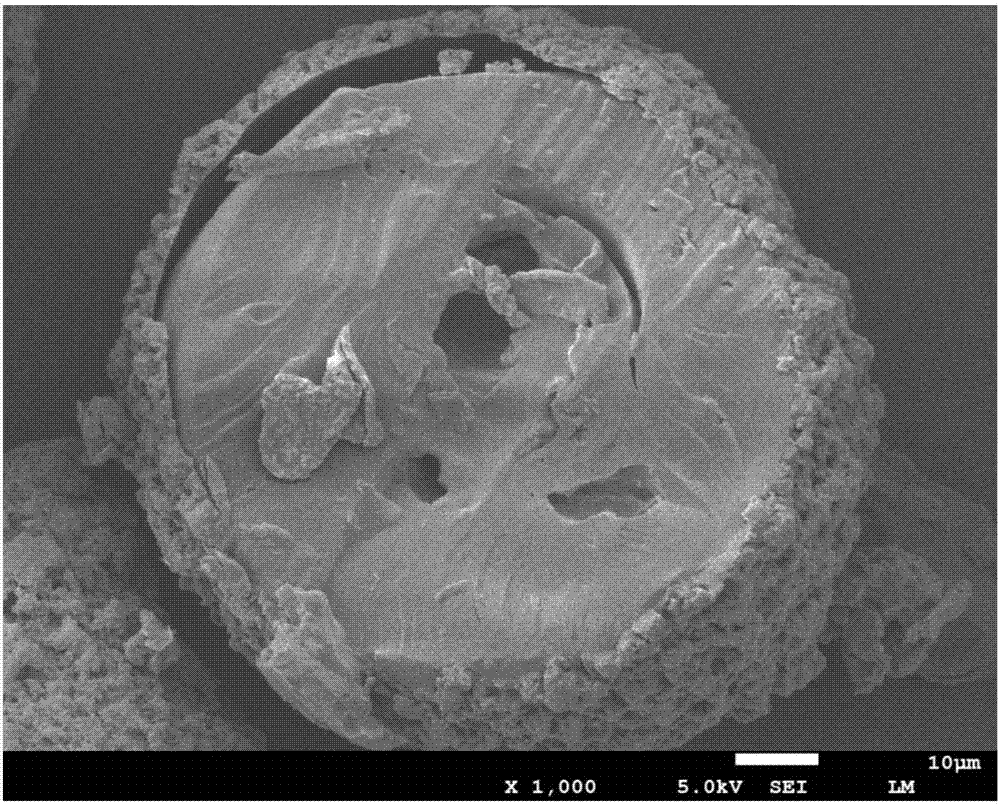

Urea formaldehyde resin-coated isocyanate microcapsule and preparation method thereof

InactiveCN107138102AShort resolution periodExtended use timeMicroballoon preparationMicrocapsule preparationIsocyanateChemistry

The invention provides a urea formaldehyde resin-coated isocyanate microcapsule and belongs to the field of microcapsule composite material preparation. The urea formaldehyde resin-coated isocyanate microcapsule is prepared from 29 to 53% by weight of water, 1.85 to 17.02% by weight of formaldehyde, 2 to 27% by weight of urea, 0.1 to 2% by weight of an emulsifier, 0.2 to 6% by weight of a system stabilizer, 17 to 32% by weight of isocyanate, 2 to 6% by weight of an isocyanate protecting agent, 0.05 to 3% by weight of an acidic pH adjuster and 0.05 to 3% by weight of an alkaline pH adjusting agent. The urea formaldehyde resin-coated isocyanate microcapsule utilizes urea formaldehyde resin as a capsule coating isocyanate so that liquid isocyanate forms a solid state. The method prevents isocyanate volatilization, masks odor of isocyanate and prolongs an isocyanate use time. The urea formaldehyde resin-coated isocyanate microcapsule has high activity and controllable particle sizes and is easy to transport and store.

Owner:NORTHEAST FORESTRY UNIVERSITY

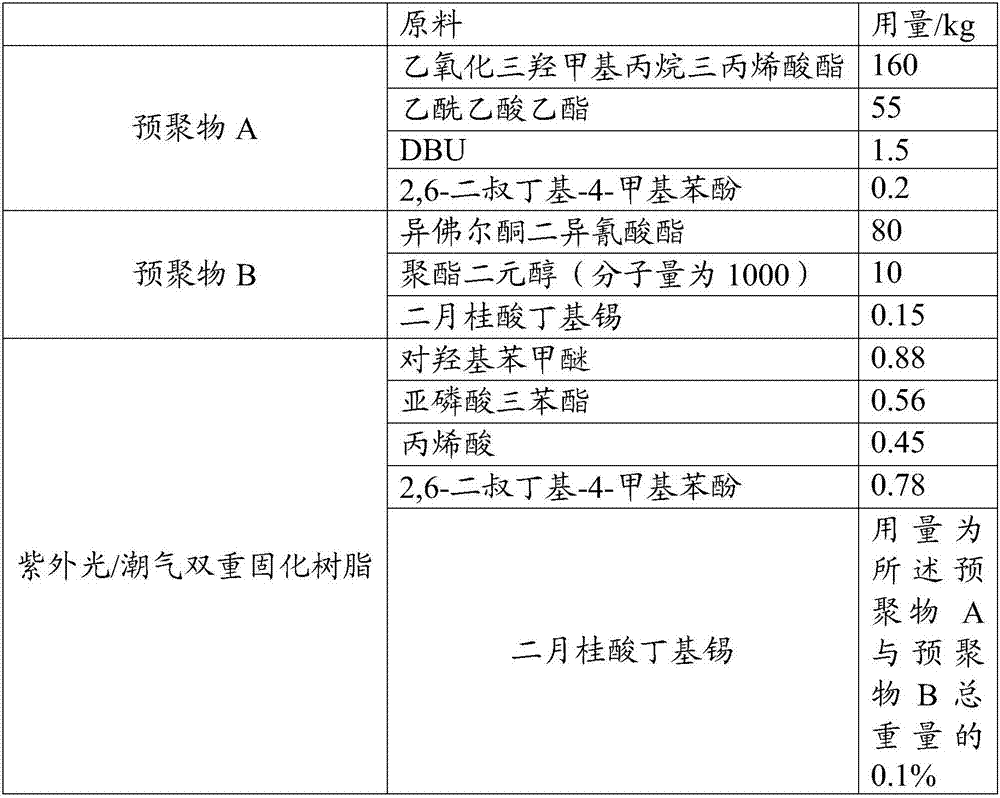

Ultraviolet/moisture dual-cured resin as well as preparation method and application thereof

ActiveCN107446483AStable storageEasy constructionPolyurea/polyurethane coatingsPolyesterAdhesion force

The invention relates to ultraviolet / moisture dual-cured resin as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) preparation of a prepolymer A, namely, adding a catalyst and a polymerization inhibitor to catalyze acrylic ester compounds and beta-ketone ester to perform Michael addition reaction; (2) preparation of a prepolymer B, namely, heating polyester glycol to 70 to 90 DEG C, adding a catalyst and fat diisocyanate, and stirring and reacting for 2 to 3 hours; (3) preparation of the ultraviolet / moisture dual-cured resin, namely, mixing the prepolymer A and the prepolymer B, adding a catalyst, stirring, heating to 80 to 90 DEG C, reacting until the NCO content in a mixed liquid is 8 to 13 percent, adding the polymerization inhibitor, and discharging to obtain the ultraviolet / moisture dual-cured resin. The ultraviolet / moisture dual-cured resin prepared with the preparation method is high in curing speed, high in solid content and high in NCO content; a prepared paint film has the excellent compressive performance, such as resistance to chemicals, adhesion force and high temperature resistance.

Owner:中山市千佑化学材料有限公司

Solvent-free waterborne polyisocyanate curing agent and preparation method and application thereof

ActiveCN108659191AGood dispersionGood storage stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDispersityPolyurethane adhesive

The invention discloses a solvent-free waterborne polyisocyanate curing agent and a preparation method and application thereof. The solvent-free waterborne polyisocyanate curing agent is polyisocyanate prepolymer containing sulfonic acid groups. The preparation method includes: dissolving dicarboxyl sulfonate into an organic solvent, allowing the solution to have reaction with polyisocyanate prepolymer, and distilling to remove the organic solvent to obtain the solvent-free waterborne polyisocyanate curing agent. The solvent-free waterborne polyisocyanate curing agent is truly free of VOC discharge, excellent in water dispersity and storage stability, high in NCO content, low in viscosity, capable of being coordinated with various resin containing hydroxyl, carboxyl or amino to prepare double-component polyurethane coating and double-component polyurethane adhesive, and capable of allowing a product to be good in water resistance and high in strength.

Owner:FOSHAN JINGXIN HUIMING TECH CO LTD

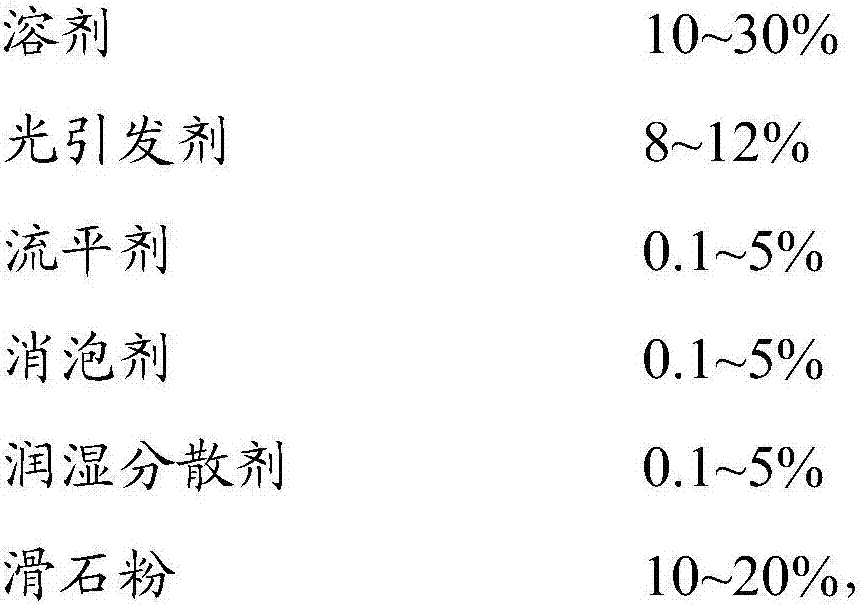

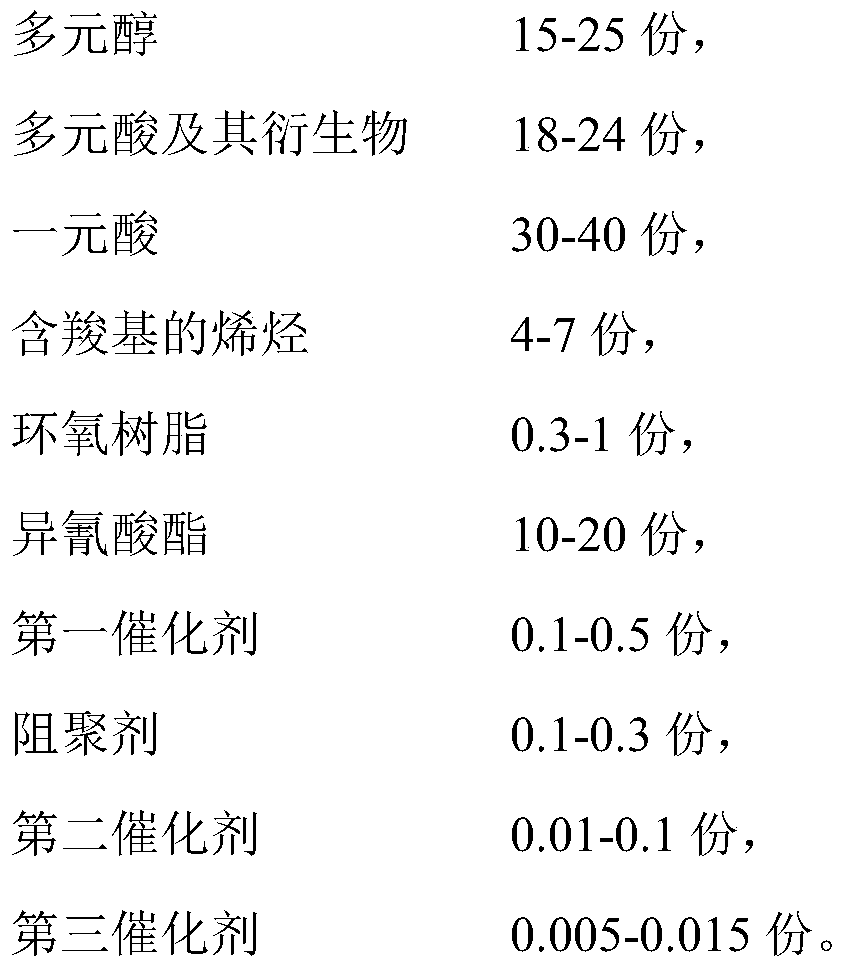

Zero-VOC radiation curable/moisture curing resin and preparation method thereof

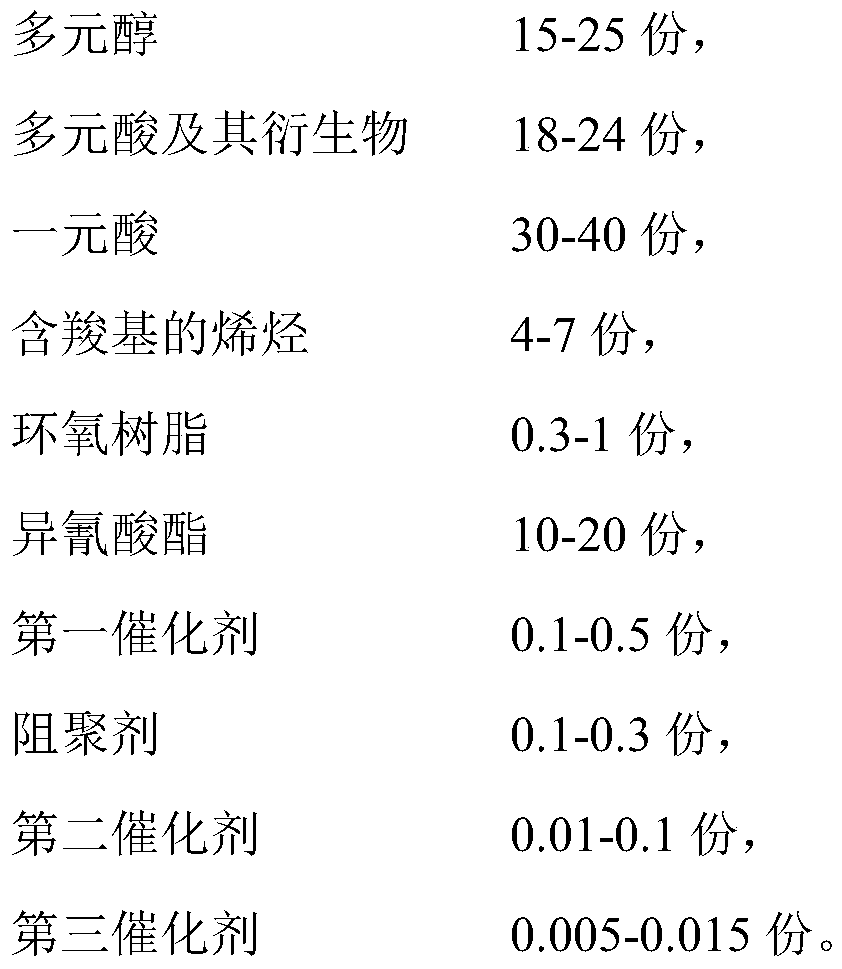

The invention discloses zero-VOC radiation curable / moisture curing resin and a preparation method thereof. The zero-VOC radiation curable / moisture curing resin comprises the following raw materials, in parts by weight: 15-25 parts of a polyol, 18-24 parts of a polyacid and a derivative of the polyacid, 30-40 parts of a monoacid, 4-7 parts of a carboxyl-containing olefin, 0.3-1 part of epoxy resin,10-20 parts of isocyanate, 0.1-0.5 part of a first catalyst, 0.1-0.3 part of a polymerization inhibitor, 0.01-0.1 part of a second catalyst, and 0.005-0.015 part of a third catalyst. The product provided by the invention has low viscosity, strong adhesion, no solvent and no volatile organic compound emission, and is green and environmentally friendly; and the preparation method is simple and easyto implement, the preparation costs are low, no three wastes (waste water, waste gas and solid waste) are generated in the synthetic process, and the industrialized production is easy to realize.

Owner:JIANGMEN PAINT FACTORY

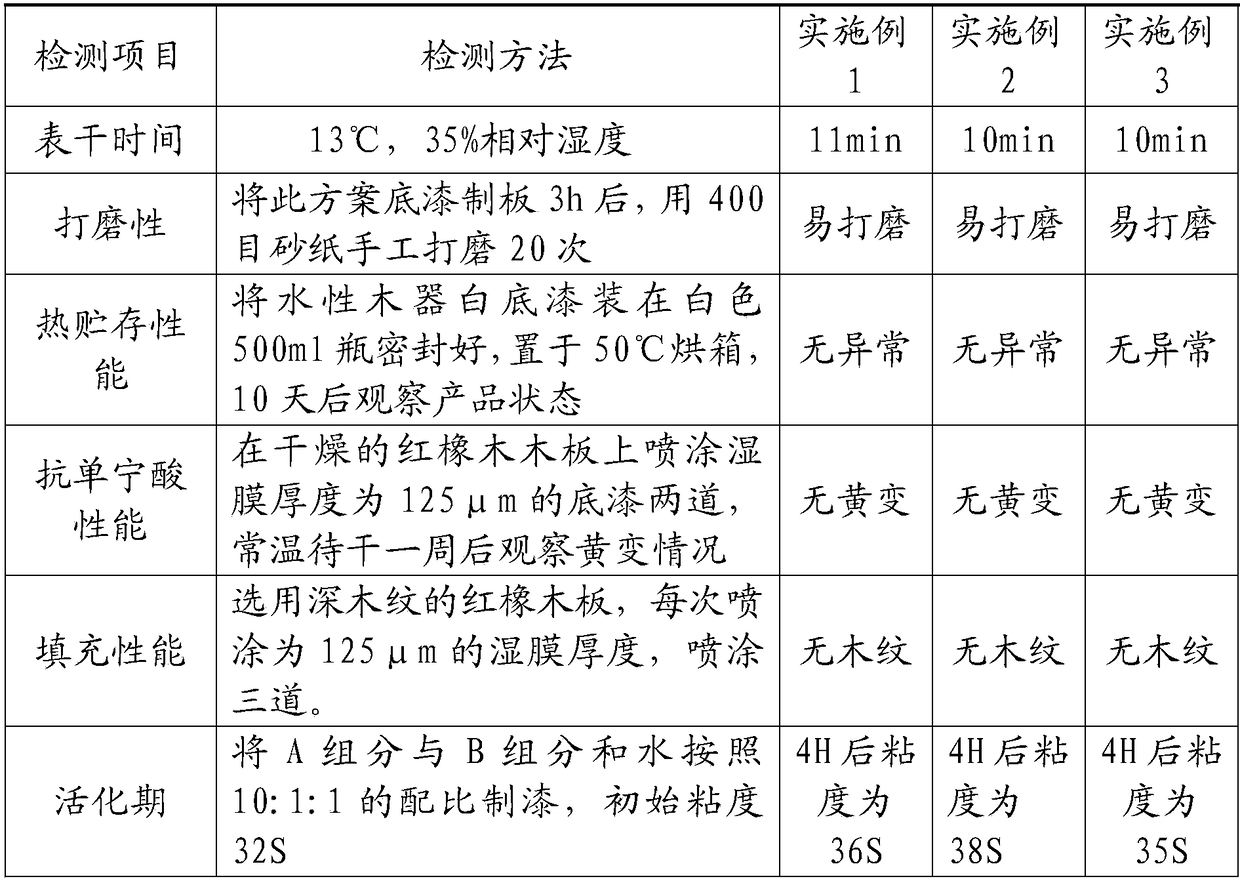

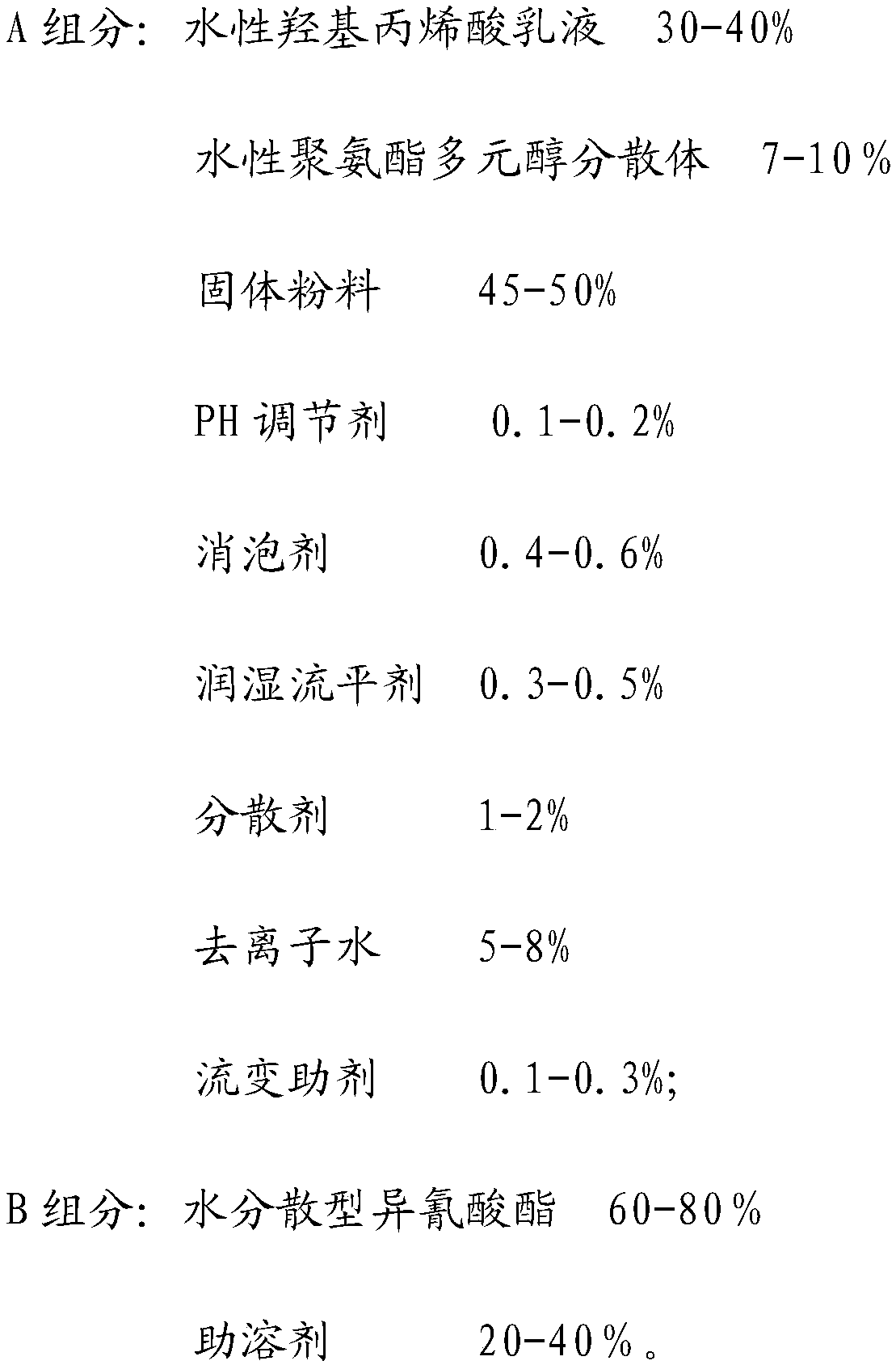

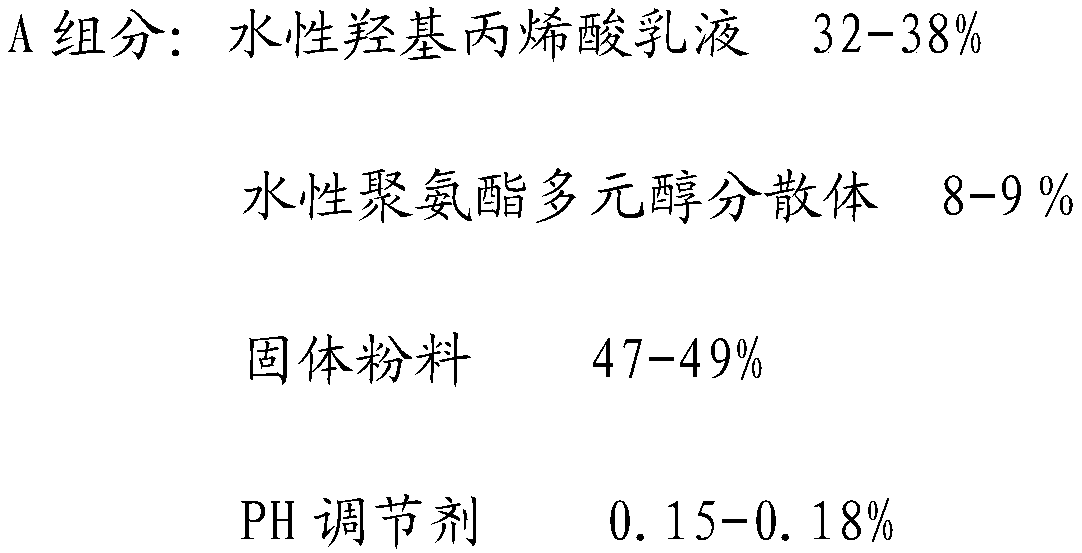

High solid content and economical tannic acid resistant two-component white environment-friendly waterborne primer

InactiveCN108948992AGood recombinationImprove water resistancePolyurea/polyurethane coatingsPriming paintsWater basedPolyol

The invention discloses a high solid content and economical tannic acid resistant two-component white environment-friendly waterborne primer. The preparation method includes: adding a dispersant intodeionized water and performing dispersion, then adding a PH regulator, then adding a defoamer and conducting high speed dispersion, then adding solid powder and performing high speed dispersion; adding a water-based hydroxyl acrylic emulsion and a waterborne polyurethane polyol dispersion into another new material preparation pot, and adding a mixture of a neutralizer and deionized water at an intermediate speed to obtain an emulsion; adding a defoamer and a wetting leveling agent into the emulsion and performing high speed dispersion so as to obtain a mixed solution c for standby use; addinga prepared white pulp into the mixed solution c, then adding deionized water and a rheological assistant to obtain a component A; mixing water dispersed isocyanate and a cosolvent evenly to obtain a component B; and mixing the component A and the component B evenly in a proportion of 10:1, thus obtaining the environment-friendly waterborne primer. The waterborne primer prepared according to the invention has the advantages of low cost, good environmental protection effect, good stability and strong practicability.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

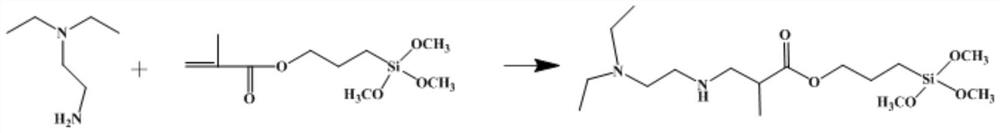

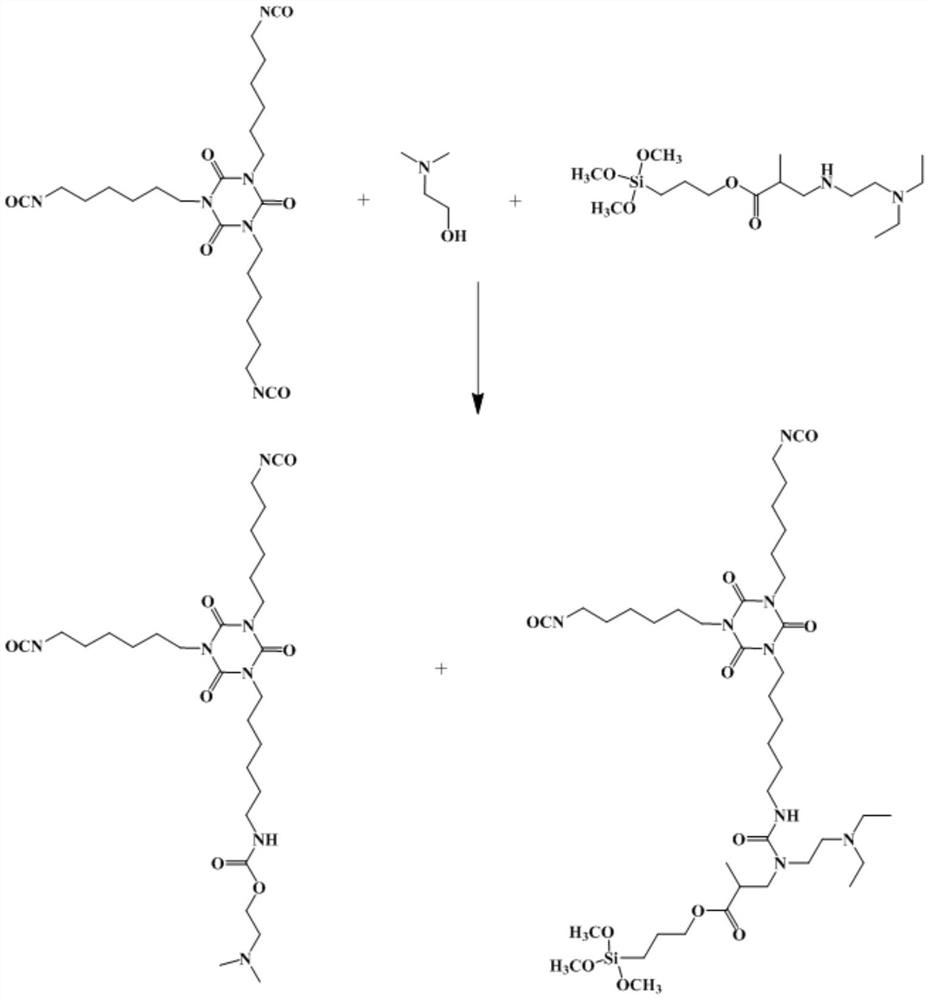

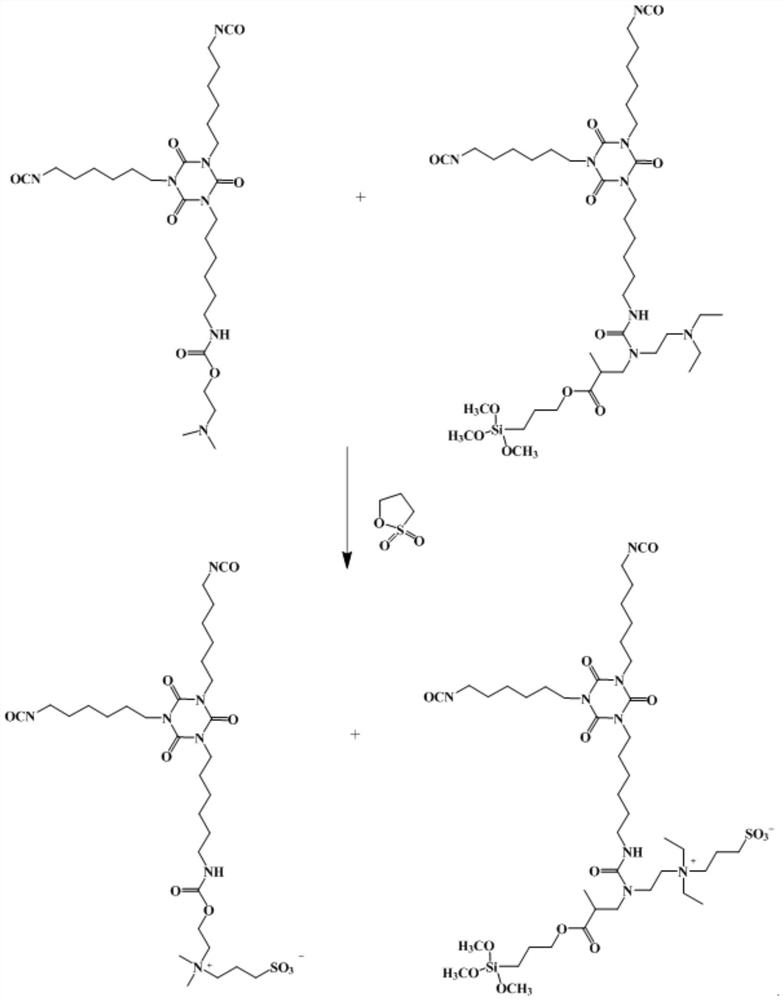

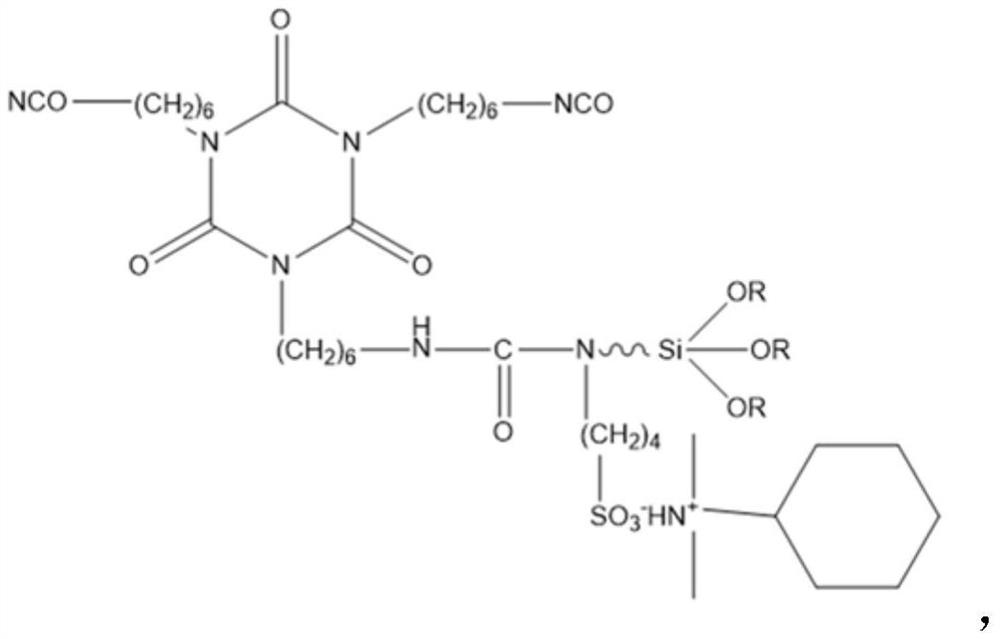

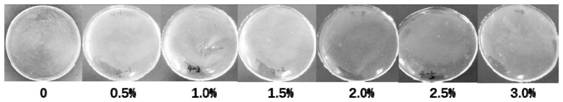

Silane hybrid quaternary ammonium salt modified polyisocyanate curing agent and preparation method thereof

ActiveCN112210069ALight colorLow viscosityGroup 4/14 element organic compoundsAntifouling/underwater paintsNitrogen atmosphereLactone

The invention provides a silane hybrid quaternary ammonium salt modified polyisocyanate curing agent and a preparation method thereof. The preparation method includes the steps that by mass, 1.0-3.0%of alkylol amine, 2.0-4.0% of silane coupling agent and 90-94% of polyisocyanate react under the protection of the nitrogen atmosphere at the temperature of 40-60 DEG C till the NCO content of the system reaches a theoretical value, 0.05-0.5% of polymerization inhibitor is added, and thus a silane hybrid polyisocyanate curing agent containing tertiary amine is prepared; and then 2.0-4.0% of sultone is added to react with the silane hybrid polyisocyanate curing agent containing tertiary amine until the sultone is completely consumed, and cooling and discharging are conducted. By adopting the sultone hydrophilic modifier with strong hydrophilicity, the prepared curing agent can be dispersed in water, is low in viscosity and environment-friendly, and has the characteristics of excellent scratch resistance, transparency, storage stability and the like.

Owner:肇庆千江高新材料科技股份公司

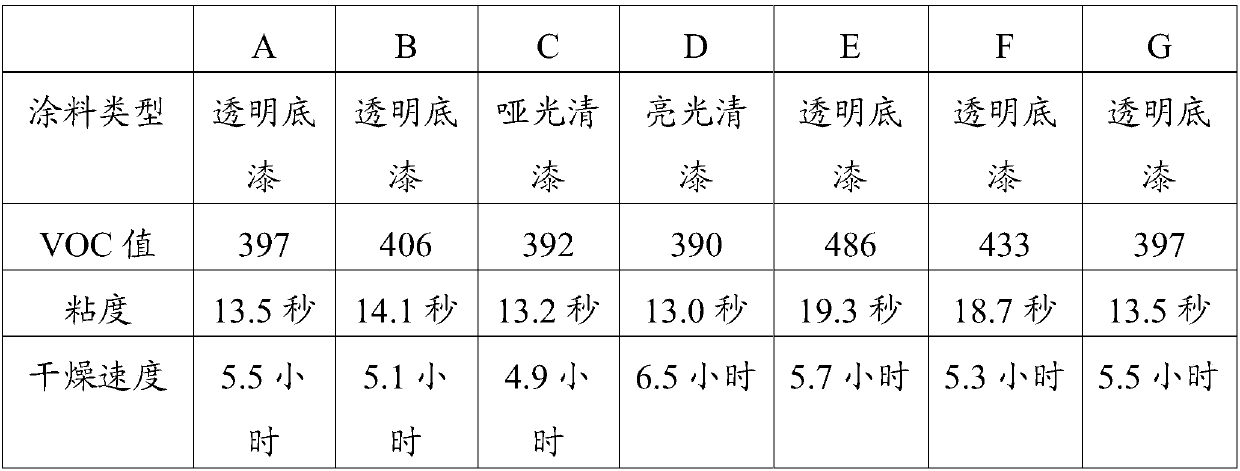

Two-component polyurethane coating with low emission of volatile organic compounds (VOC), and preparation method of polyurethane coating

InactiveCN107674575ALow viscosityReduce usagePolyurea/polyurethane coatingsDefoaming AgentsDiphenylmethane diisocyanate

The invention relates to a two-component polyurethane coating with low emission of volatile organic compounds (VOC). The polyurethane coating is prepared from a component A, a component B and a component C, wherein the weight ratio of the component A to the component B to the component C is equal to 1 to (2 to 3) to (0.5 to 1); the component A is prepared from 10-30 parts of a diisocyanate prepolymer and 70-90 parts of diphenylmethane diisocyanate; the component B is prepared from 50-80 parts of short-oil alkyd resin, 5-25 parts of an organic solvent, 0-0.5 part of a dispersing agent, 0-5 parts of extinction powder, 0-1.0 part of wax powder, 0-15 parts of talcum powder, 0-3.0 parts of an anti-settling agent, 0-0.5 part of a leveling agent, 0.1-0.5 part of a defoaming agent and 0.1-0.3 partof a drying catalyst; the component C is prepared from 70-90 parts of butyl acetate and 10-30 parts of propylene glycol methyl ether acetate. The two-component polyurethane coating provided by the invention is prepared from the high solid content raw materials, so that the consumption of the solvent is effectively reduced; the VOC emission of the polyurethane coating is about 400g / L, so that thepolyurethane coating is especially suitable for being applied and popularized to finishing and painting of wood furniture.

Owner:CARPOLY CHEM GRP

Preparation method of polyurethane prepolymer with low free isocyanate monomer

The invention discloses a preparation method of polyurethane prepolymer with low free isocyanate monomer. The preparation method comprises the following steps of: forming into mixed alcohol by trihydric alcohol and dihydric alcohol under the temperature of 120-150DEG C, and carrying out vacuum dehydration; putting isocyanate monomer and ester solvents into a reactor to keep the temperature at 30-70DEG C, and dropwise adding the mixed alcohol into the reactor; after dropwise adding, continuously reacting for 3-6h under the temperature of 40-70DEG C under stirring, and discharging in a cooling way to obtain polyurethane prepolymer; and separating the obtained polyurethane prepolymer, and adjusting the solid content of polyurethane prepolymer solid and the content of free isocyanate monomer in the separated heavy components by diluted solvent. According to the preparation method, the real continuous production can be realized, all the recovered solvent and isocyanate monomer can be recycled, the zero emission can be realized, and the real clean production can be realized; and the product has the characteristics of being low in viscosity, high and adjustable in NCO value content, low in the content of the free isocyanate monomer, high in solid content, good in compatibility, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

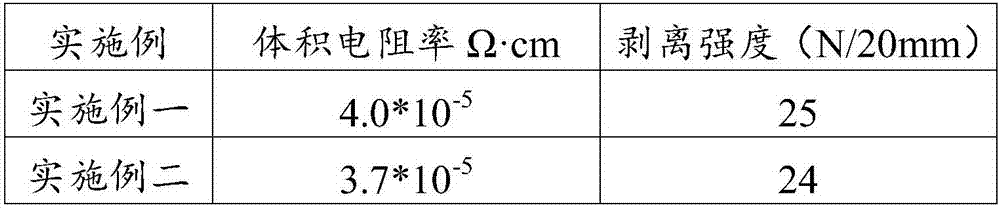

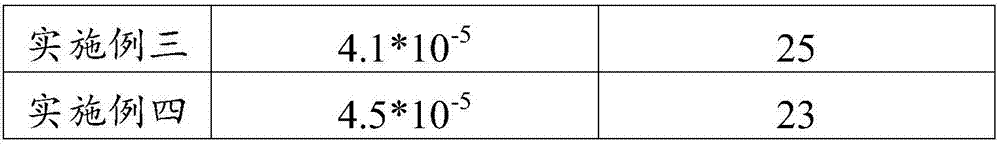

Polyurethane adhesive, preparation method thereof and conductive adhesive tape

InactiveCN106978127AEvenly dispersedPromote migrationNon-macromolecular adhesive additivesFilm/foil adhesivesPolyesterPolyol

The invention discloses a preparation method of a polyurethane adhesive. The preparation method comprises the following steps: (1) adding polyester polyol into a reaction kettle, and carrying out vacuum dehydration for 4-6 hours; (2) adding isocyanate, a combined solvent, a catalyst and a cross-linking agent into the reaction kettle of the step (1), heating to 80-90 DEG C, and reacting for 2-4 hours; (3) dissolving nano-nickel powder into the combined solvent, adding the combined solvent into the reaction kettle of the step (2), and uniformly mixing; and (4) carrying out vacuum distillation on substances in the reaction kettle of the step (3) at 80-90 DEG C, cooling, and discharging, so as to obtain the polyurethane adhesive. The polyurethane adhesive prepared by virtue of the preparation method is good in conductivity and high in peel strength.

Owner:东莞市普力达光学材料科技有限公司

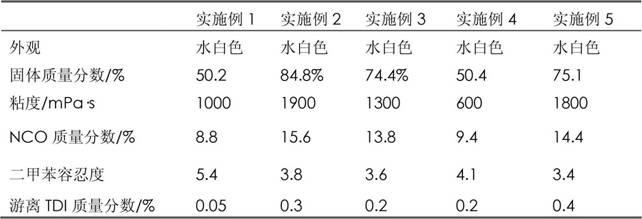

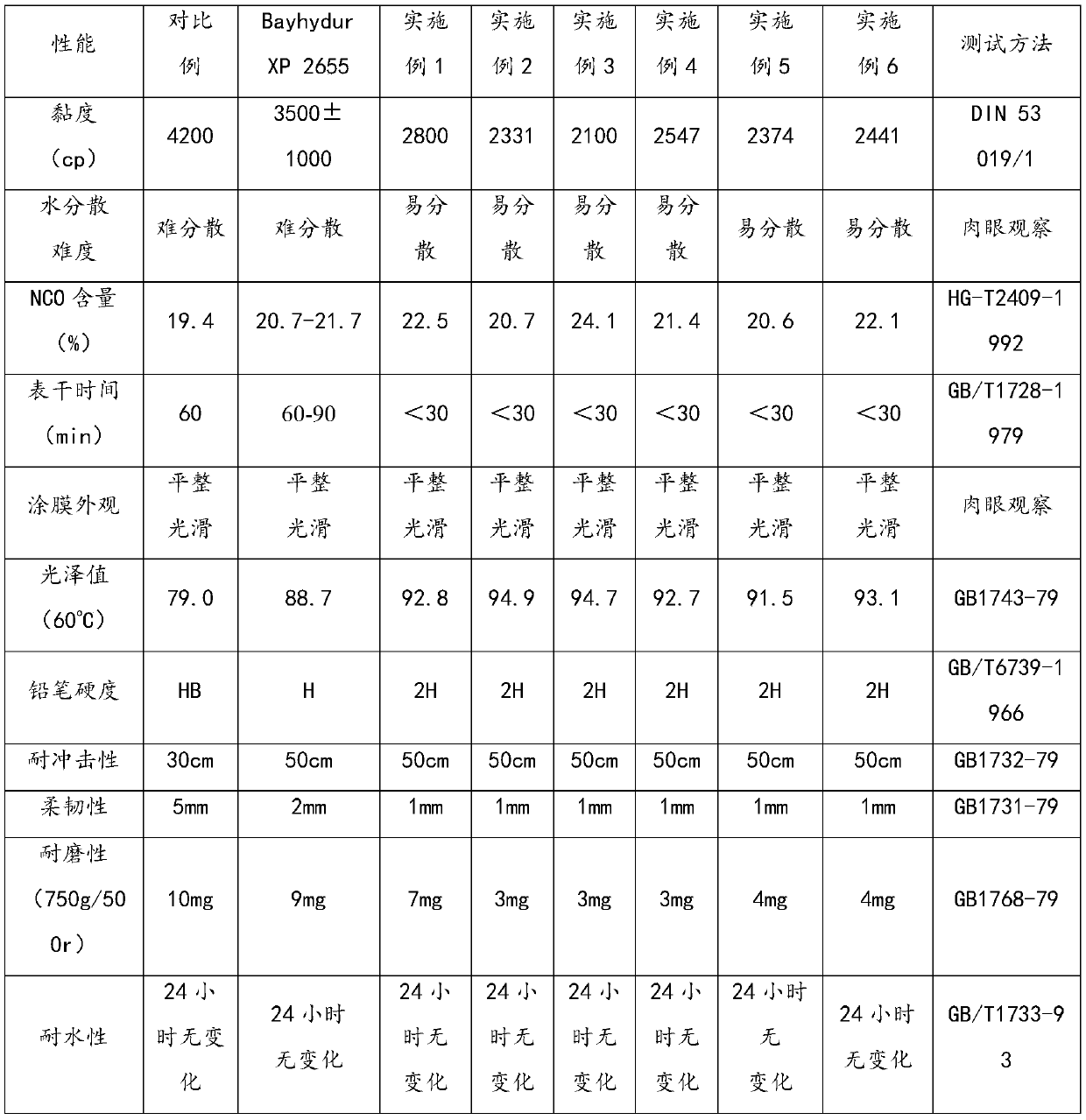

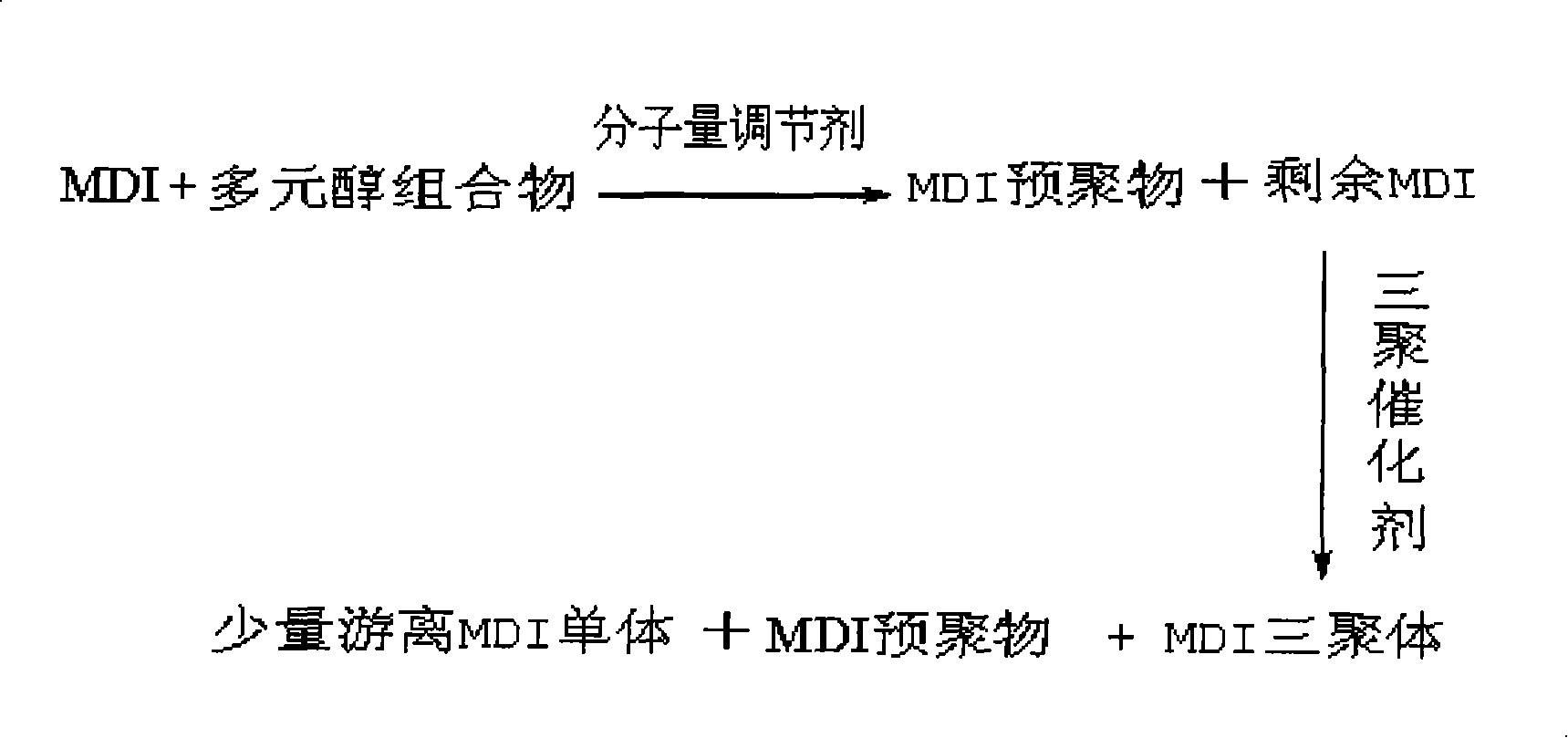

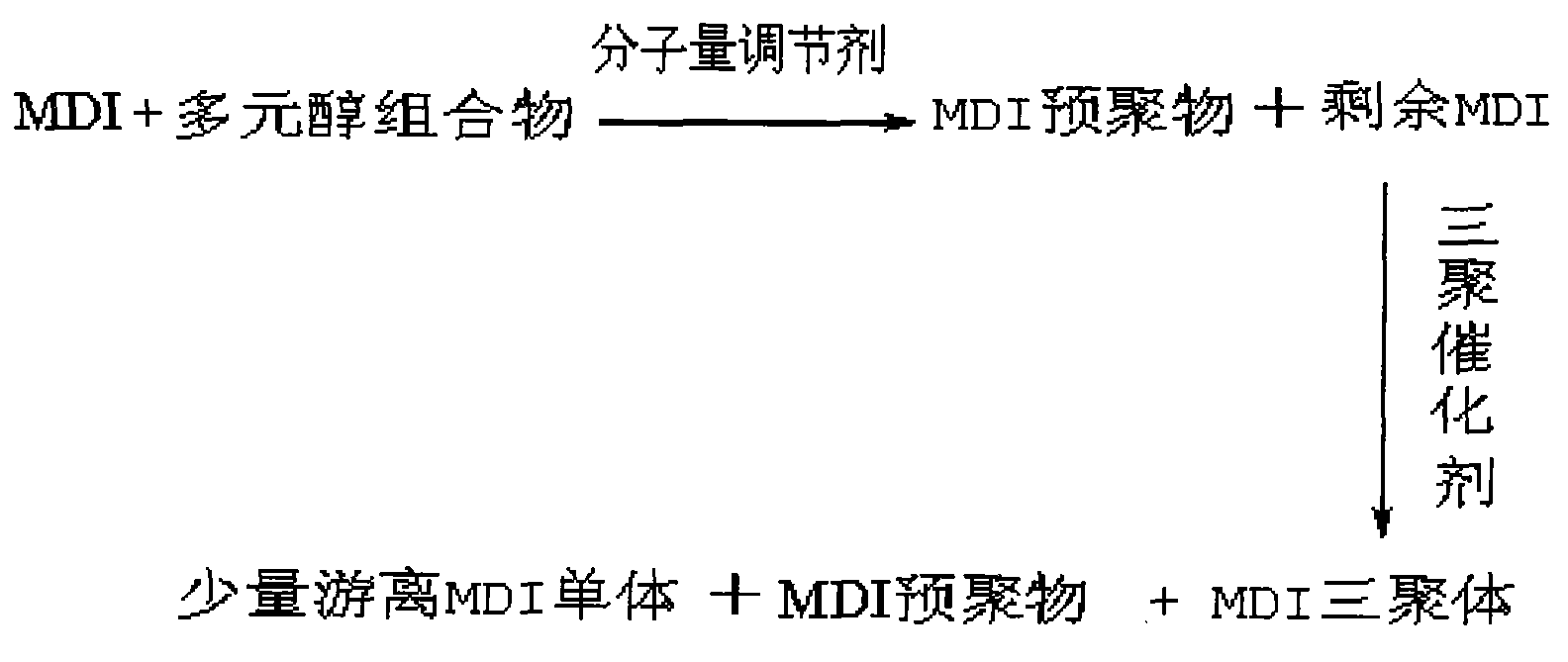

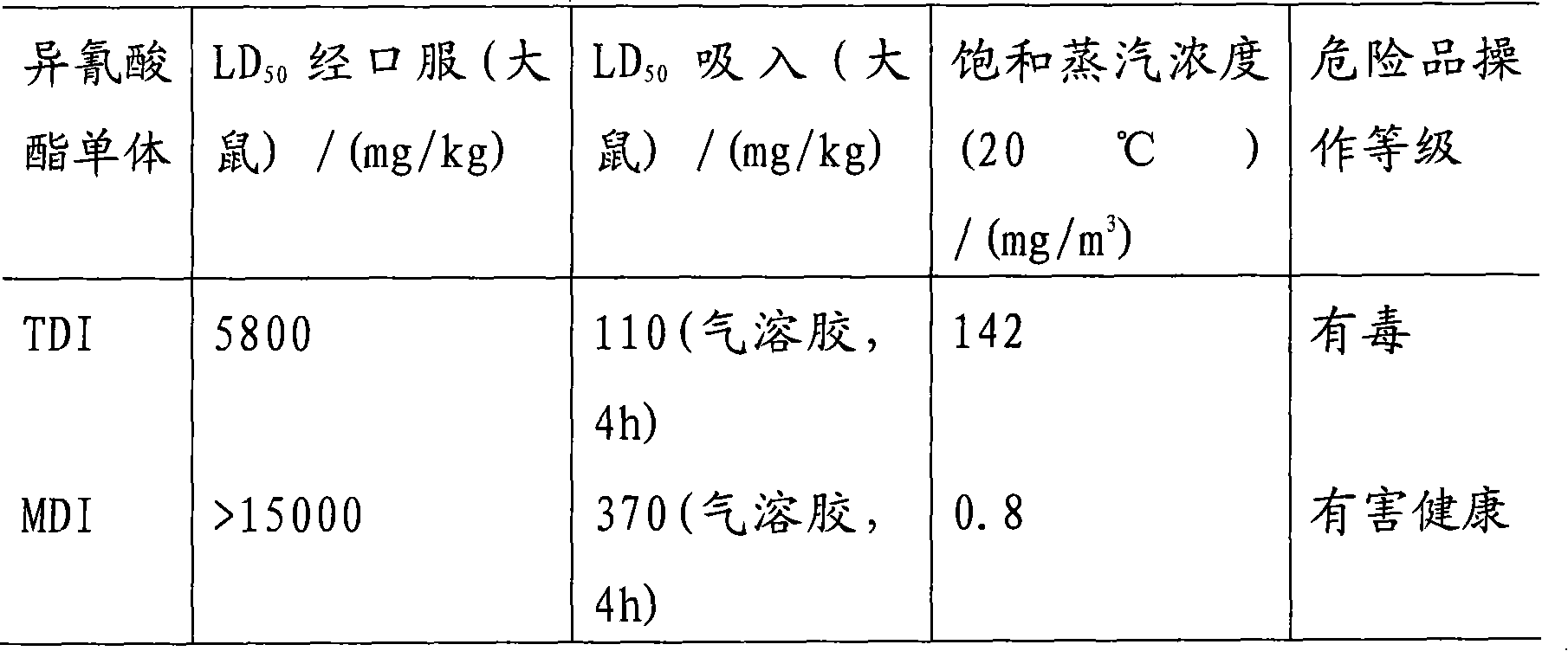

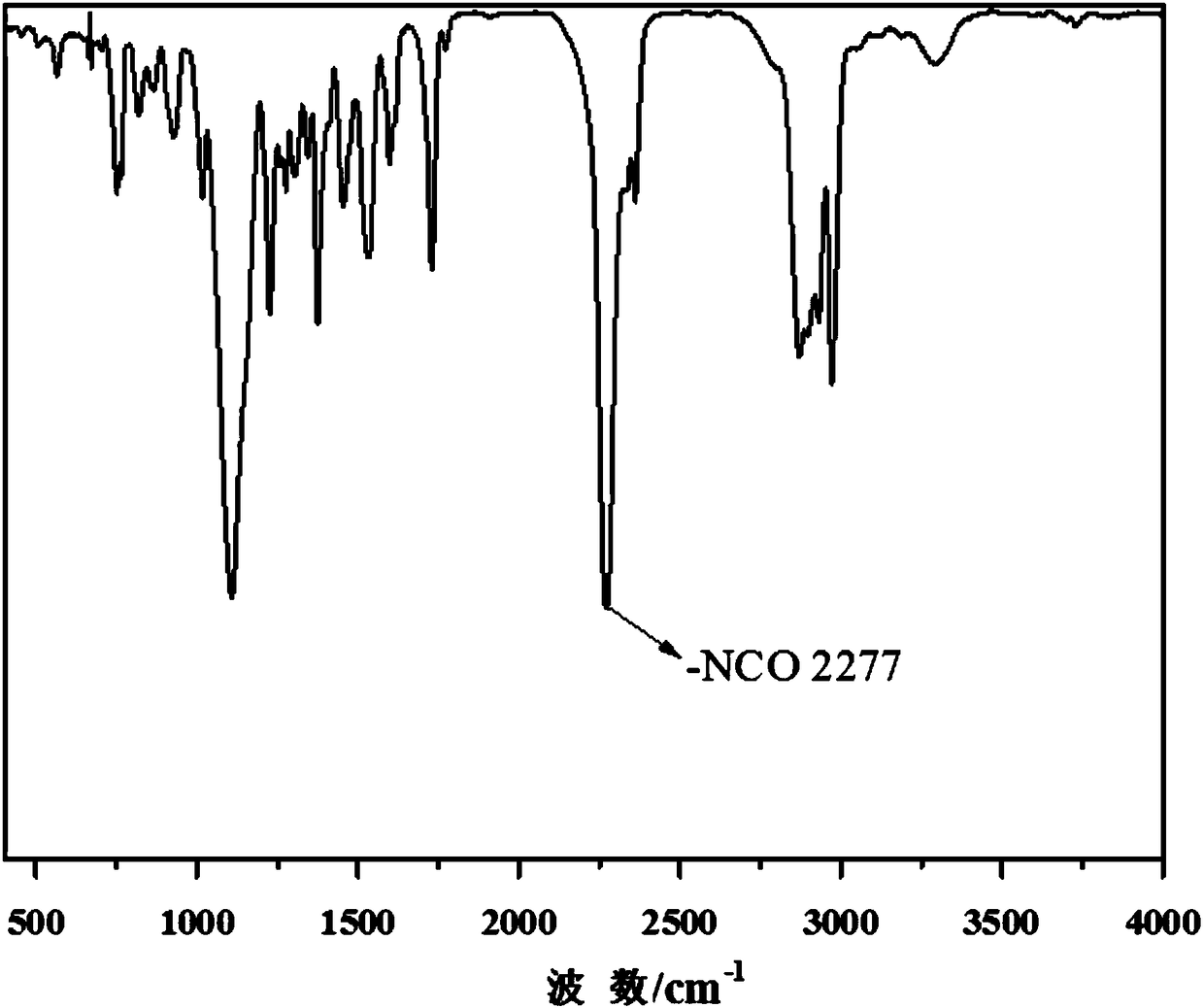

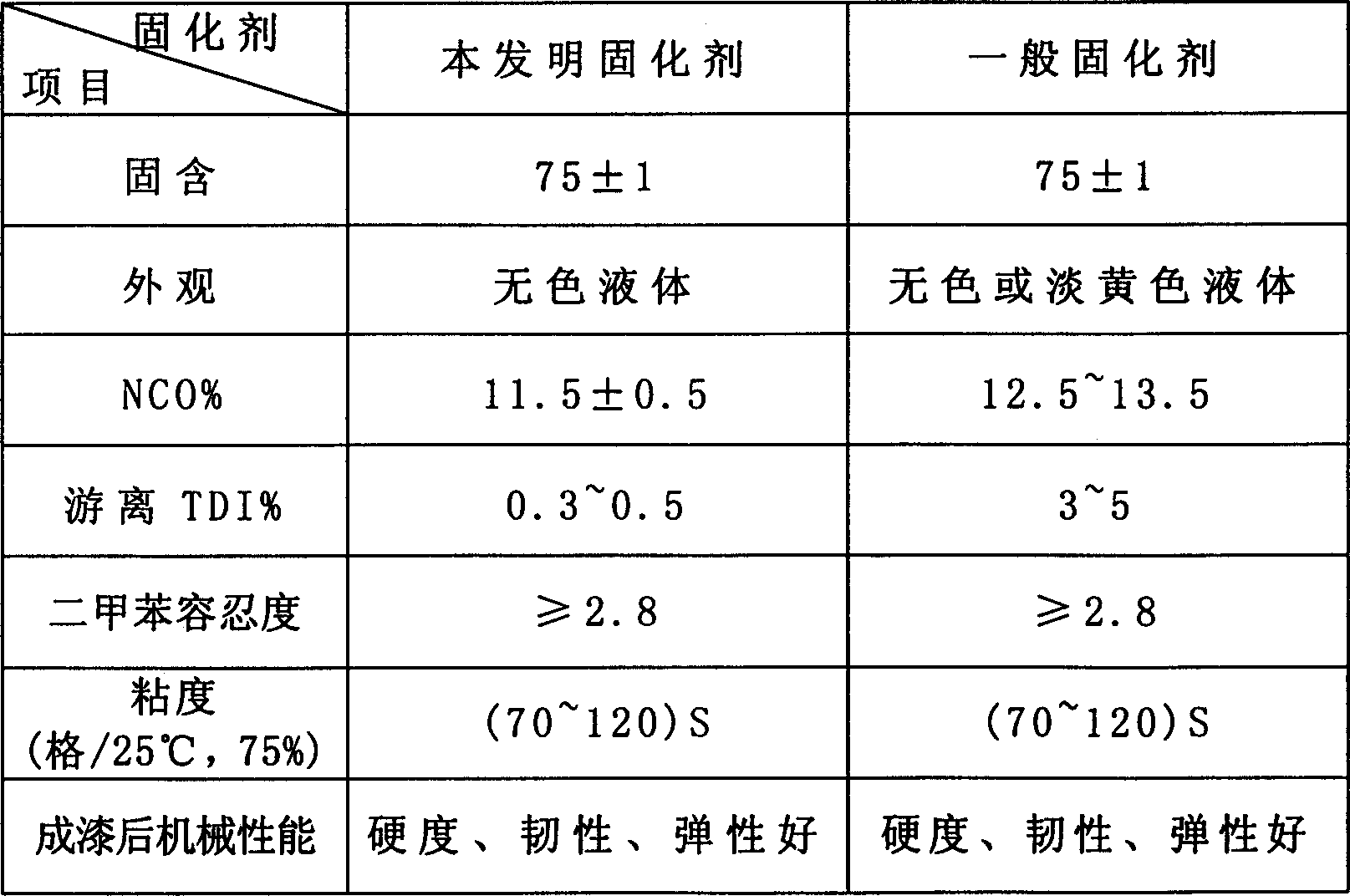

Polyurethane curing agent with low free MDI monomer and method for preparing same

InactiveCN101307127BHigh NCO contentReduce sensitivityPolyureas/polyurethane adhesivesPolyolProcess equipment

The invention discloses a polyurethane firming agent with low free MDI monomers and a method for preparing the same. The invention solves the problems that the prior art has complex MDI polyurethane firming agent preparation process and high equipment investment. The technical proposal comprises the following steps that: the step one, a molecular weight modifying agent is added into a compositionof MDI and polylol; prepolymerization reaction is carried out in a solvent, wherein, the equivalent proportion of NCO to OH is 3-5 to 1; and the adding amount of the molecular weight modifying agent is 1 to 1.5 percent of the MDI mass; step two, after the prepolymerization reaction is finished, a trimeric catalyzer is added into the solvent for trimerization reaction; the adding amount of the trimeric catalyzer is 0.1 to 0.3 percent of the residual MDI mass theoretically after the reaction in the step one; after the trimerization reaction is finished, a polymerization inhibitor is added into the solvent to terminate the reaction. The process method has low production cost and simple process equipment; the prepared firming agent has stable storage, low toxicity and performances which can meet various requirements of the firming agent of sizing agent for packing a composite membrane; when the solid content is 75 percent, the content of free MDI monomers is less than 2 percent of the firming agent mass.

Owner:武汉仕全兴新材料科技股份有限公司

A kind of polyurethane prepolymer and preparation method thereof

The invention discloses a polyurethane prepolymer and a preparation method thereof. The isocyanate group content MNCO in the polyurethane prepolymer is 4-10%, and the viscosity at 25 DEG C is 1,000-4,000mPa.s. The storage duration of the polyurethane prepolymer at room temperature is not shorter than 3 days; and the polyurethane prepolymer has the advantages of low viscosity, high NCO content, high stability and long storage duration, is used for preparing non-solvent polyurethane and can improve the performance of the non-solvent polyurethane material.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

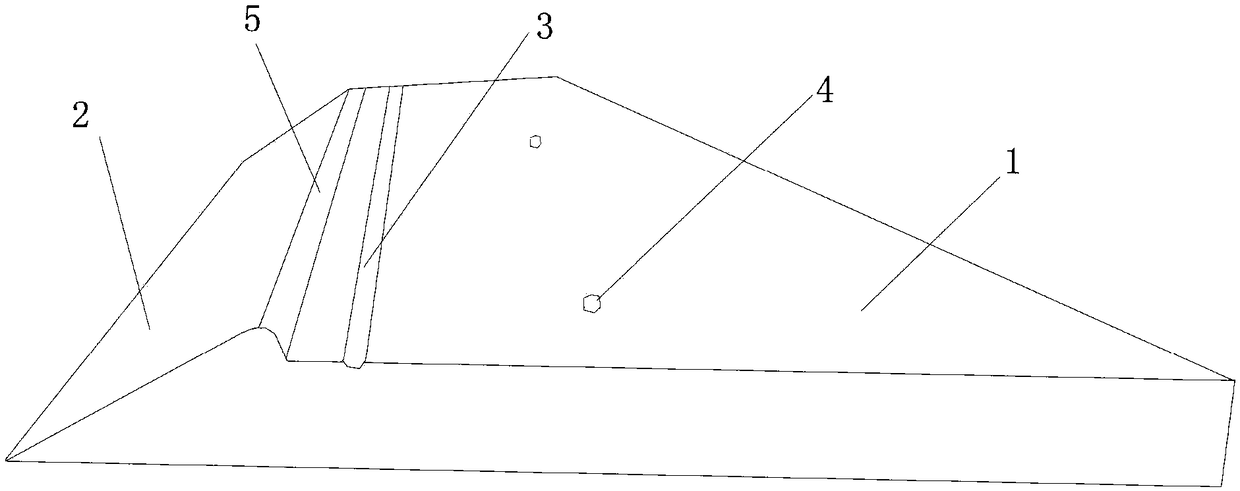

Polyurethane material for making chicken manure scraper of farm

The invention relates to a polyurethane material for preparing a chicken manure scraper of a farm. The invention is characterized in that: the scraper comprises a support portion and a wedge portion,the height of the wedge portion is greater than the height of the support portion to form a flange, the angle formed by an oblique side of the wedge portion and a bottom side of the support portion is20 to 40 degrees, the oblique side of the wedge portion is perpendicular to an upper side of the support portion, the flange has an angle of 50 to 70 degrees and is rounded; the support portion and the wedge portion are integrally molded; the scraper material is polyurethane; and the scraper material is made of the following parts by weight of raw materials: PTMG is added with TDI, so that the -NCO content in a synthesized prepolymer is 6.8%, and the prepolymer is added to MOCA. The invention has the beneficial effects that the angle of the wedge portion is arranged to fit a conveyor belt, the scraping of the manure is realized, and the polyurethane material has large frictional force to avoid slipping and rusting in the water environment.

Owner:QINGDAO RUIXINHE IND TRADE

Method for preparing polyurethane modified silicone two-component room temperature curing elastomer adhesive

ActiveCN105018015BEasy to operateShorten the production cycleNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElastomerAdhesive

Owner:道一高分子聚合物(宁波)有限公司

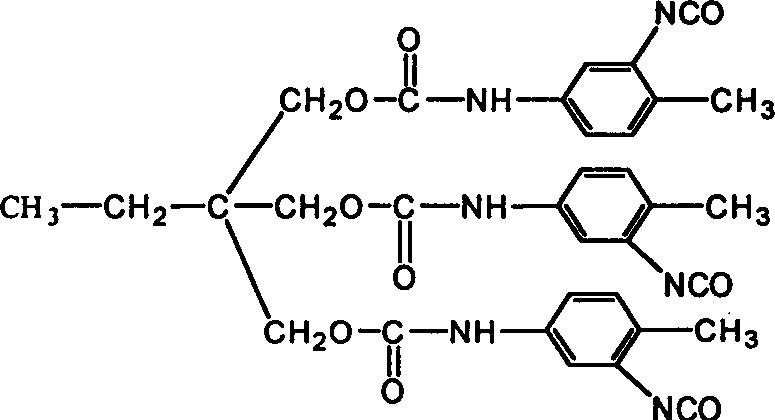

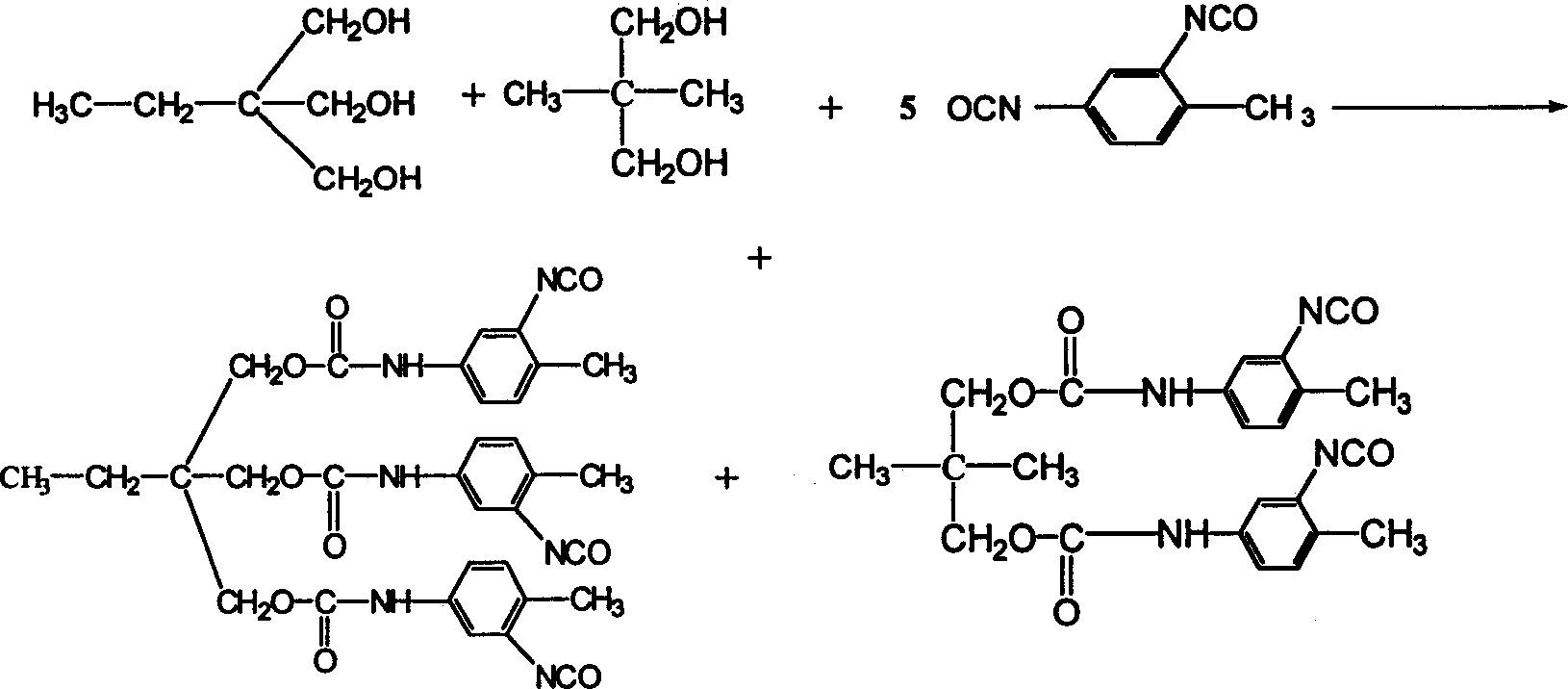

Process for preparing low free toluene diisocyanate curing agent

The preparation process of low free toluene diisocyanate as curing agent includes the following steps: reaction between toluene diisocyanate and polyol in the NCO / OH molar ratio 2-3 at 50-80 deg.c with reaction medium SO2, gamma-butrrolactone, dimethhyl sulfoxide, dimethyl carboxy diacid ester; adding polyisocyanate polymerizing catalyst when the content of NCO is 15-16 % for further reaction and adding polyisocyanate polymerizing inhibitor when the content of NCO is 14-15%; adding fatty hydrocarbon and / or cyclic fatty hydrocarbon as extracting agent for multiple extraction, eliminating the extracting agent through letting stand or distillation; and diluting and discharging pre-polymer. The present invention can prepare curing agent with low chroma, low visosity and high NCO content and no toluene diisocyanate monomer and other toxic matter.

Owner:ZHUHAI FEIYANG NOVEL MATERIALS

Hydrophilic polyurethane polymer and preparation method thereof

PendingCN114133526AReduce usageReduce contentAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceSulfamic acid

The invention relates to a hydrophilic polyurethane polymer and a preparation method thereof, and is characterized in that the hydrophilic polyurethane polymer is prepared from the following components by mass: 2-5 parts of a hydrophilic modifier composition, 95-98 parts of polyisocyanate, and 0.5-1 part of a neutralizer. The hydrophilic modifier composition comprises polyether sulfonic acid and sulfamic acid, and the polyether sulfonic acid and the sulfamic acid are prepared according to the molar ratio of 1: 0.8-1: 6. The preparation method of the hydrophilic modifier composition comprises the following steps: adding amino polyether into excessive sultone, reacting at room temperature for 4-8 hours to generate polyether type sulfonic acid, adding alkyl tertiary amine into a reaction system, reacting at room temperature for 4-8 hours to generate sulfamic acid, and dissolving the sulfamic acid in the polyether type sulfonic acid; and continuously heating to 60-100 DEG C, and reacting for 4-8 hours. The invention has the advantages of good water dispersion performance, wide application range and the like.

Owner:佛山市华联有机硅有限公司 +1

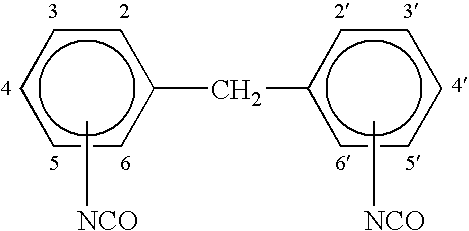

A kind of low viscosity liquefaction modified MDI and preparation method thereof

ActiveCN108329457BEscape in timeAvoid pollutionPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyurethane elastomerPtru catalyst

The invention belongs to the technical field of chemistry and particularly discloses low-viscosity liquefaction modified MDI (4,4'-diphenylmethane diisocyanate) and a preparation method thereof. The liquefaction modified MDI has the viscosity of 310-380 mPa.s and the NCO content of 18%-21%. The method comprises the steps as follows: a) MDI is added to a reactor provided with temperature control, stirring and reflux condensation devices to be heated under the protection condition of inert gas, and the temperature is kept at 50-55 DEG C until MDI is molten into a liquid; b) the temperature is increased to 78-98 DEG C, a catalyst A and mono-hydroxyl small-molecular alcohol are added, the mixture reacts completely, then, the temperature is decreased to 60-75 DEG C, and macromolecular polyols are added; c) a stabilizer B is added, the experiment is ended after 0.5-2 h, and the temperature is decreased to the room temperature. The method is low in raw material cost, simple in process and easy to control in process condition when used for synthesizing the low-viscosity liquefaction modified MDI. The low-viscosity liquefaction modified MDI has high reaction activity and good storage stability and can be used for preparing room-temperature casting polyurethane elastomers, coatings, adhesives and sealants.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

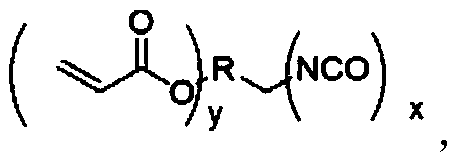

A kind of highly water-resistant and hydrophilic polyisocyanate curing agent and its preparation method and application

ActiveCN111116865BHigh NCO contentReduce viscosityGroup 4/14 element organic compoundsAnti-corrosive paintsPolymer scienceSolvent based

The invention provides a highly water-resistant and hydrophilic polyisocyanate curing agent and its preparation method and application. The polyisocyanate curing agent has the following structural formula: the polyisocyanate curing agent has a higher NCO content, lower viscosity and excellent water resistance; it is prepared with acrylic dispersions of different hydroxyl values, and the appearance of the paint film, Water resistance and other performance tests show that the polyisocyanate curing agent not only maintains the high-gloss and high-transparency appearance characteristics of water-based curing agents, but also has water resistance and other properties comparable to solvent-based curing agents, and is especially suitable for the field of metal anti-corrosion.

Owner:WANHUA CHEM GRP CO LTD +1

External cross-linking agent for waterborne polyurethane and preparation method and application of external cross-linking agent

ActiveCN111892694AGood water solubilityIncrease ionic strengthPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention relates to a preparation method of an external cross-linking agent for waterborne polyurethane. The preparation method comprises the following steps: by using imidazole ionic liquid modified hydroxyl-terminated polyether and polyisocyanate as raw materials, carrying out addition polymerization reaction under the action of a catalyst to finally obtain the external cross-linking agentfor waterborne polyurethane. The external cross-linking agent for waterborne polyurethane has nonionic and ionic hydrophilic groups and good water solubility, the water resistance, solvent resistanceand mechanical strength of a PU adhesive film can be remarkably improved, and a cross-linked coating is not sticky.

Owner:QILU UNIV OF TECH

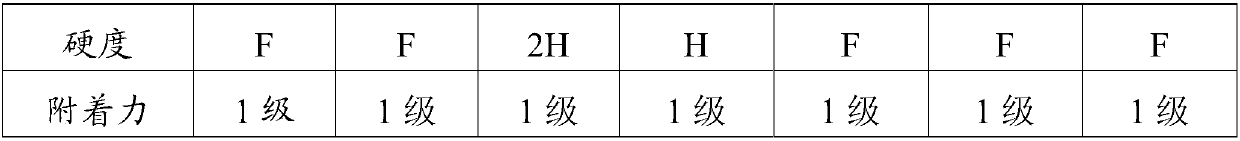

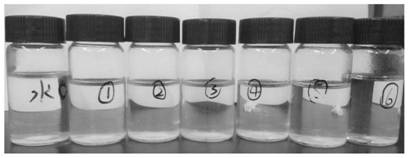

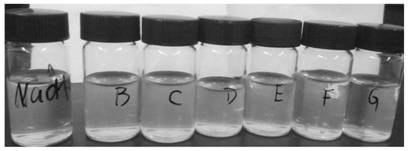

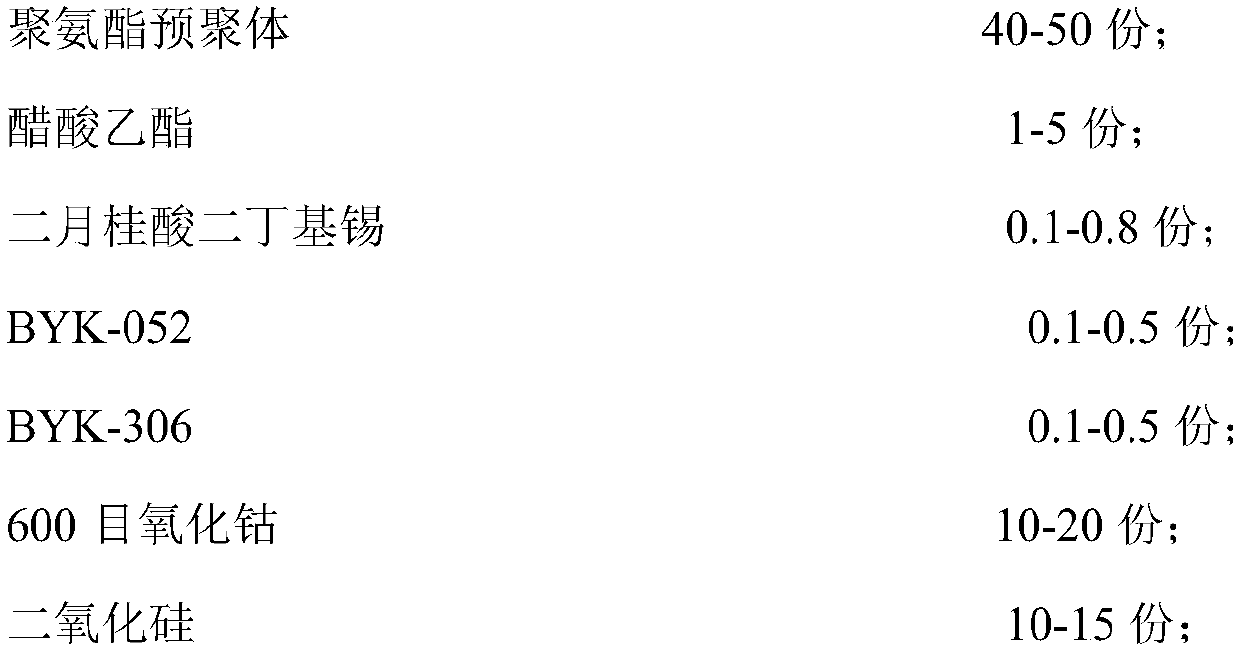

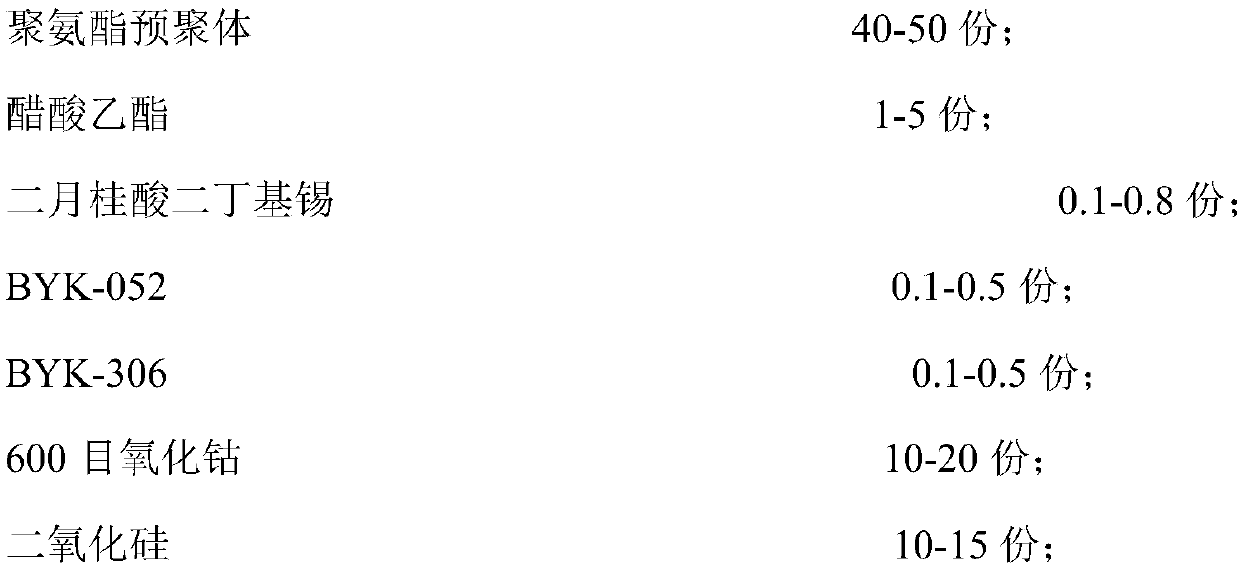

Matte super-hard weatherproof finishing material

InactiveCN109609016ALow viscosityHigh NCO contentAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyAcrylic resin

The invention relates to a matte super-hard weatherproof finishing material, which is composed of a component A and a component B. The component A comprises a polyurethane prepolymer, ethyl acetate, dibutyltin dilaurate, BYK-052, BYK-306, 600-mesh cobalt oxide and silicon dioxide; and the component B comprises hydroxyl-containing silicone resin and acrylic resin. The finishing material is sprayedon a constructed floor to improve yellowing and slippery floor materials to enable the floor material to have mechanical properties such as slip resistance, mildew proof, seepage prevention, weather resistance, and super-hardness based on pencil hardness. The finishing material is widely used in concrete-based, polyurethane-based, epoxy-based and other floors.

Owner:FUZHOU ROYAL FLOOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com