Polyurethane adhesive, preparation method thereof and conductive adhesive tape

A polyurethane adhesive and conductive tape technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as poor electrical conductivity, improve electrical conductivity, reduce electron migration, and improve electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

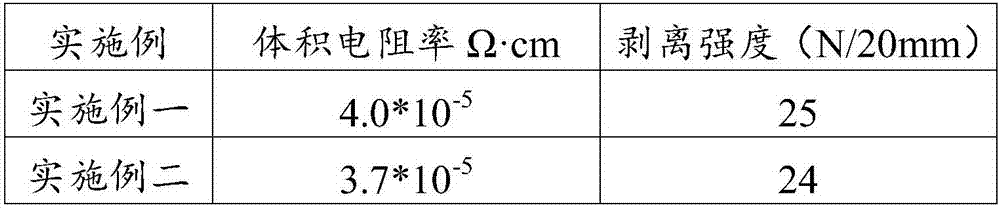

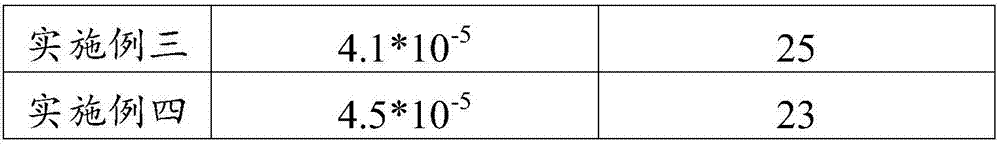

Examples

Embodiment 1

[0027] The present embodiment provides a kind of preparation method of polyurethane adhesive, comprises the steps:

[0028] Step 1: Add 10 parts by weight of polyester polyol into the reaction kettle, and vacuum dehydrate for 4 hours;

[0029] Wherein, the polyester polyol is polycarbonate polyol, specifically, polycarbonate diol, a white waxy solid with a hydroxyl value of 100 mgKOH / g, which can provide high cohesive force and high bonding strength. prepolymer.

[0030] Step 2: Add 30 parts by weight of isocyanate, 70 parts by weight of combined solvent, 1 part by weight of catalyst, and 4 parts by weight of crosslinking agent into the reactor described in step 1, heat at 80-90°C, and react for 2 hours;

[0031] Wherein, the combined solvent includes a composition of methylene chloride and acetoketone, wherein the mass ratio of methylene chloride and acetoketone is 5:1, and the combined solvent is used to improve solubility, adjust volatility, and adapt to different bonding ...

Embodiment 2

[0054] Step 1: Add 15 parts by weight of polycaprolactone polyol into the reaction kettle, and vacuum dehydrate for 5 hours.

[0055] Step 2: Add 35 parts by weight of isocyanate, 62 parts by weight of combined solvent, 3 parts by weight of catalyst, and 7 parts by weight of crosslinking agent into the reactor described in step 1, heat at 80-90°C, and react for 3 hours;

[0056] Wherein, the combined solvent comprises a composition of methylene chloride and acetone, wherein the mass ratio of methylene chloride and acetone is: 8:1;

[0057] Described isocyanate comprises the composition of toluene diisocyanate and diphenylmethane diisocyanate, and the mass ratio of toluene diisocyanate and diphenylmethane diisocyanate is: 7:1;

[0058] The catalyst is 2,2-dimorpholino diethyl ether; the crosslinking agent is trimethylol propane.

[0059] Step 3: Dissolve 5 parts by weight of nano-nickel powder in 21 parts by weight of combined solvent, add the reaction kettle described in step...

Embodiment 3

[0063] Step 1: Add 12 parts by weight of polycaprolactone polyol into the reaction kettle, and vacuum dehydrate for 6 hours.

[0064] Step 2: Add 40 parts by weight of isocyanate, 50 parts by weight of combined solvent, 2 parts by weight of catalyst, and 8 parts by weight of crosslinking agent into the reactor described in step 1, heat at 80-90°C, and react for 4 hours;

[0065] Wherein, the combined solvent comprises a composition of methylene chloride and acetone, wherein the mass ratio of methylene chloride and acetone is: 10:1;

[0066] Described isocyanate comprises the composition of toluene diisocyanate and diphenylmethane diisocyanate, and the mass ratio of toluene diisocyanate and diphenylmethane diisocyanate is: 7:1;

[0067] The catalyst is 2,2-dimorpholino diethyl ether; the crosslinking agent is hexanetriol.

[0068] Step 3: Dissolve 5 parts by weight of nano-nickel powder in 21 parts by weight of combined solvent, add the reaction kettle described in step 2, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com