Ultraviolet/moisture dual-cured resin as well as preparation method and application thereof

A dual-curing, ultraviolet light technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the difficult to meet the comprehensive performance requirements of coatings such as chemical resistance, adhesion, high temperature resistance, colored systems and thick coating curing Low conversion rate, low energy consumption and emission, etc., to achieve good oil sealing effect, good bottom sealing effect and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

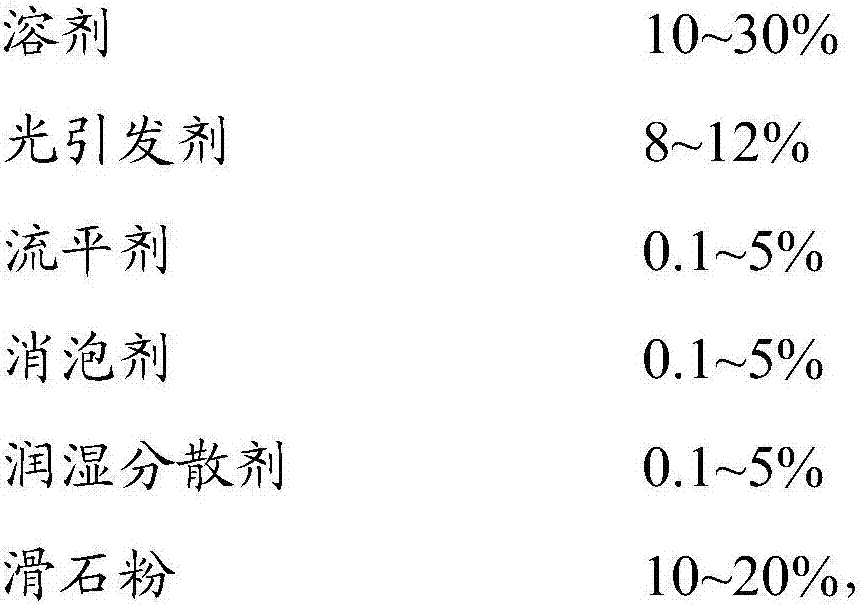

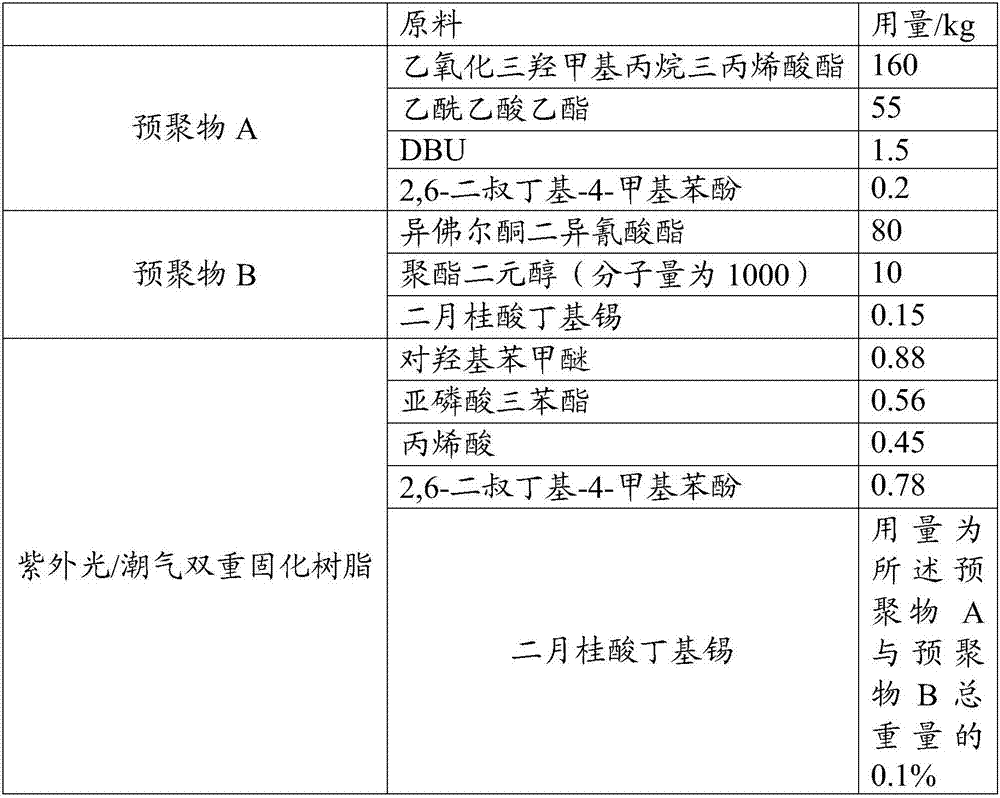

[0041] In this embodiment, a kind of ultraviolet light / moisture dual curing resin, its preparation raw materials are as follows:

[0042]

[0043] The preparation method of the above-mentioned ultraviolet light / moisture dual curing resin is as follows:

[0044] (1) Preparation of prepolymer A: Add ethoxylated trimethylolpropane triacrylate and 2,6-di-tert-butyl-4-methylphenol into the reaction kettle, heat up to 60°C, add DBU, start Ethyl acetoacetate was added dropwise, and after the dropwise addition was completed, the temperature was raised to 80°C for Michael addition reaction, and the reaction was performed for 2 hours to obtain prepolymer A;

[0045] (2) Preparation of prepolymer B: heat up polyester diol to 70°C, then add isophorone diisocyanate and catalyst butyltin dilaurate, heat up to 90°C, stir and react for 2 hours to obtain prepolymer B; wherein, the molar ratio of the polyester diol to the aliphatic diisocyanate is 1:36;

[0046](3) Preparation of UV / moistu...

Embodiment 2

[0048] In this embodiment, a kind of ultraviolet light / moisture dual curing resin, its preparation raw materials are as follows:

[0049]

[0050] The preparation method of the above UV / moisture dual curing resin is similar to Example 1.

Embodiment 3

[0052] In this embodiment, a kind of ultraviolet light / moisture dual curing resin, its preparation raw materials are as follows:

[0053]

[0054]

[0055] The preparation method of the above UV / moisture dual curing resin is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com