Two-component polyurethane coating with low emission of volatile organic compounds (VOC), and preparation method of polyurethane coating

A polyurethane coating, two-component technology, applied in the field of coatings, can solve the problems of limited construction conditions, limited application fields, unable to completely replace oil-based coatings, etc., and achieve the effect of reducing VOC and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

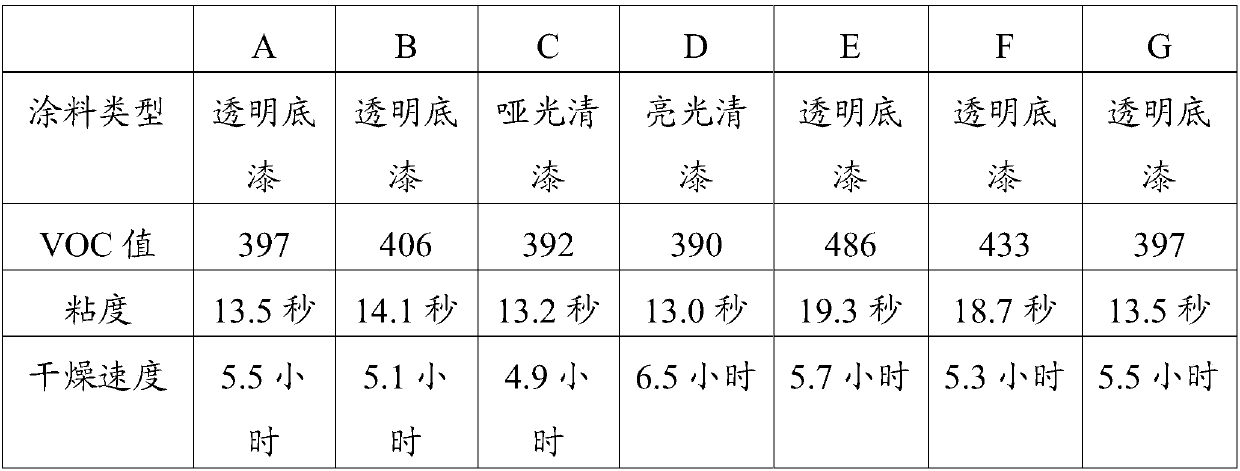

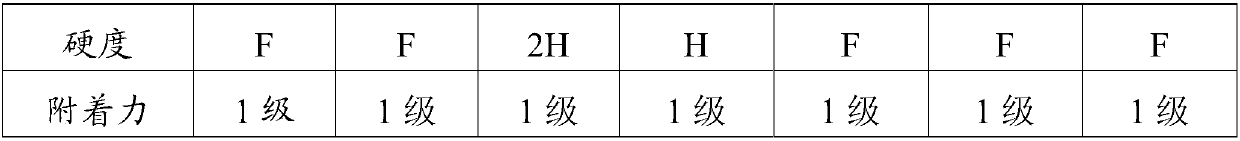

Examples

Embodiment 1

[0040] This embodiment provides a kind of two-component low-VOC polyurethane coating, comprises A component, B component and C component;

[0041] Component A includes: 15 parts of diisocyanate prepolymer L75, 85 parts of diphenylmethane diisocyanate prepolymer MDI-50F;

[0042] Component B includes: 68 parts of short oil alkyd resin H139-90, 12.1 parts of organic solvent butyl acetate, 10 parts of organic solvent propylene glycol methyl ether acetate, 8 parts of talcum powder, 1.5 parts of anti-settling agent, and 0.3 parts of defoamer , 0.1 part of drier.

[0043] C component includes: 75 parts of butyl acetate, 25 parts of propylene glycol methyl ether acetate.

[0044] The preparation method is as follows:

[0045] Component A: Feed the diisocyanate prepolymer and diphenylmethane diisocyanate prepolymer into the closed volume in sequence, and stir at 300-500 rpm for 15 minutes to obtain the component A coating;

[0046] Component B: Mix short oil alkyd resin, butyl acet...

Embodiment 2

[0050] The present embodiment provides a kind of low VOC polyurethane paint, comprises A component, B component and C component;

[0051] Component A includes: 10 parts of diisocyanate prepolymer L75, 90 parts of diphenylmethane diisocyanate prepolymer MDI-50F;

[0052] Component B includes: 60 parts of short oil alkyd resin H139-90, 15.4 parts of organic solvent butyl acetate, 7 parts of organic solvent propylene glycol methyl ether acetate, 0.2 parts of dispersant, 15 parts of talcum powder, 2 parts of anti-settling agent, 0.3 part of defoamer, 0.1 part of drier.

[0053] C component includes: 75 parts of butyl acetate, 25 parts of propylene glycol methyl ether acetate.

[0054] The preparation method is as follows:

[0055] Component A: Feed the diisocyanate prepolymer and diphenylmethane diisocyanate prepolymer into the closed volume in sequence, and stir at 300-500 rpm for 15 minutes to obtain the component A coating;

[0056]Component B: Mix short oil alkyd resin, but...

Embodiment 3

[0060] The present embodiment provides a kind of low VOC polyurethane paint, comprises A component, B component and C component;

[0061] Component A includes: 10 parts of diisocyanate prepolymer L75, 90 parts of diphenylmethane diisocyanate prepolymer MDI-50F;

[0062] Component B includes: 70 parts of short oil alkyd resin H139-90, 12.9 parts of organic solvent butyl acetate, 8 parts of organic solvent propylene glycol methyl ether acetate, 0.5 parts of dispersant, 5 parts of matting powder, 1 part of wax powder, 1.5 parts of sinking agent, 0.2 parts of leveling agent, 0.3 parts of defoamer, and 0.1 part of drier.

[0063] C component includes: 75 parts of butyl acetate, 25 parts of propylene glycol methyl ether acetate.

[0064] The preparation method is as follows:

[0065] Component A: Feed the diisocyanate prepolymer and diphenylmethane diisocyanate prepolymer into the closed volume in sequence, and stir at 300-500 rpm for 15 minutes to obtain the component A coating; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com