Polyurethane curing agent with low free MDI monomer and method for preparing same

A polyurethane curing agent, low free technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as increased product cost, increased product sensitivity to humidity, product turbidity, etc. Low investment and operating costs, good production safety and stability, and the effect of eliminating post-processing

Inactive Publication Date: 2010-12-01

武汉仕全兴新材料科技股份有限公司

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

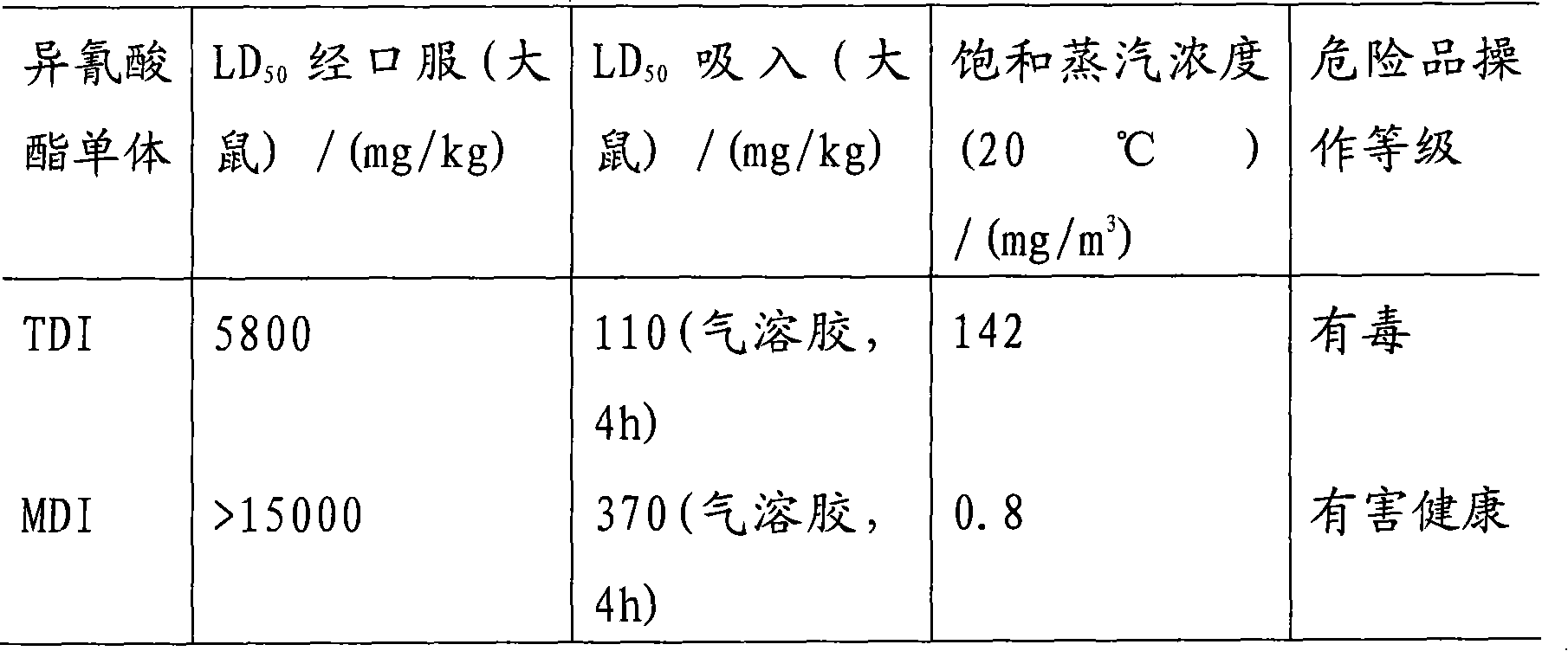

In addition, free MDI monomers can cause health and safety hazards and reduce product performance. For example, too much free MDI monomers will undergo dimerization reactions, resulting in the precipitation of insoluble matter, making the product turbid and increasing the sensitivity of the product to humidity. property, the migration of small molecular monomers to the interface leads to a decrease in adhesion, etc.

Therefore, in the curing agent preparation process, the residual amount of MDI monomer should be reduced as much as possible. At present, foreign companies have complicated processes for removing free MDI monomer. The MDI monomer prepolymer with monomer content requires the use of large-scale equipment such as scraper type thin film evaporators, etc. These equipment have high initial investment and complex process operations, which greatly increase the product cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Login to View More

Abstract

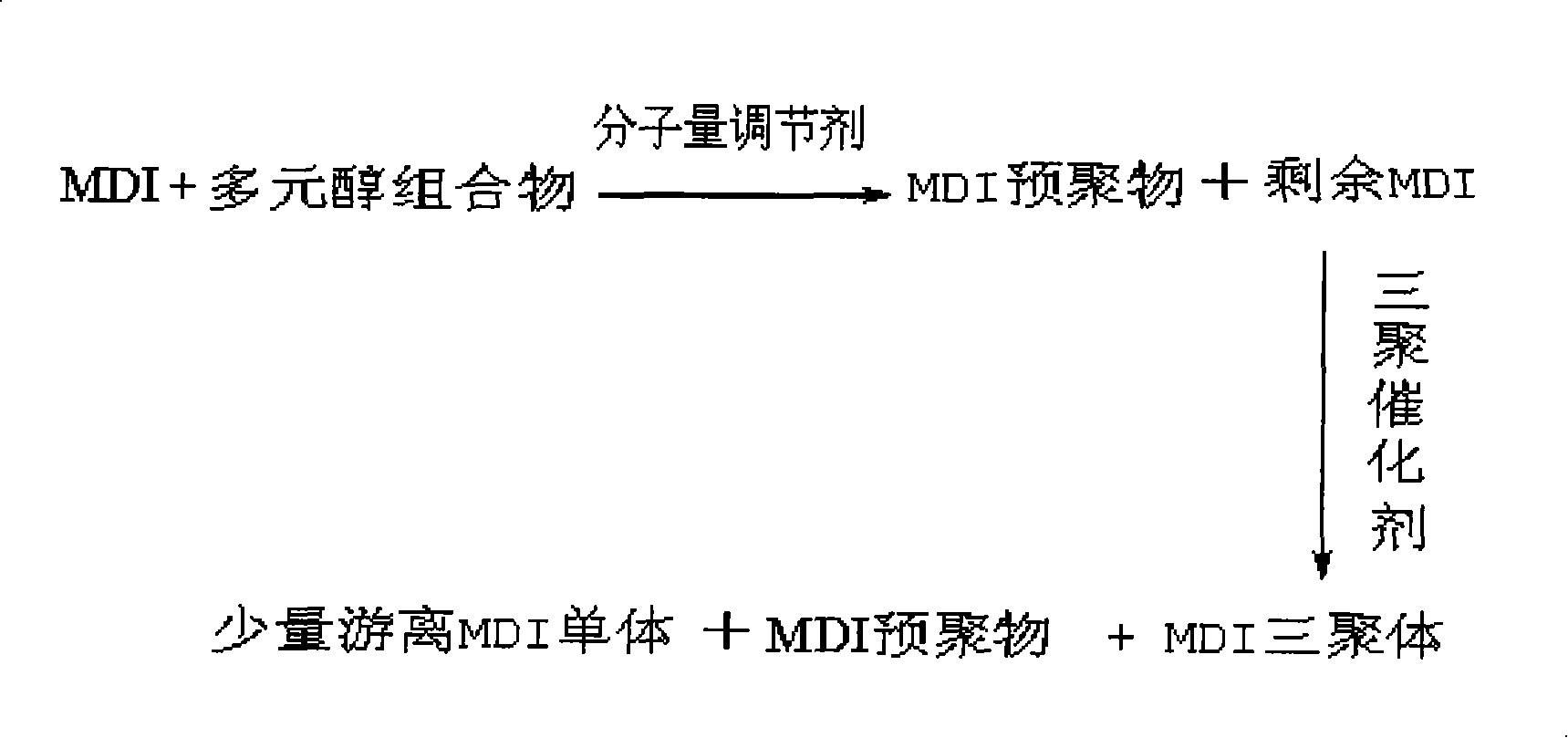

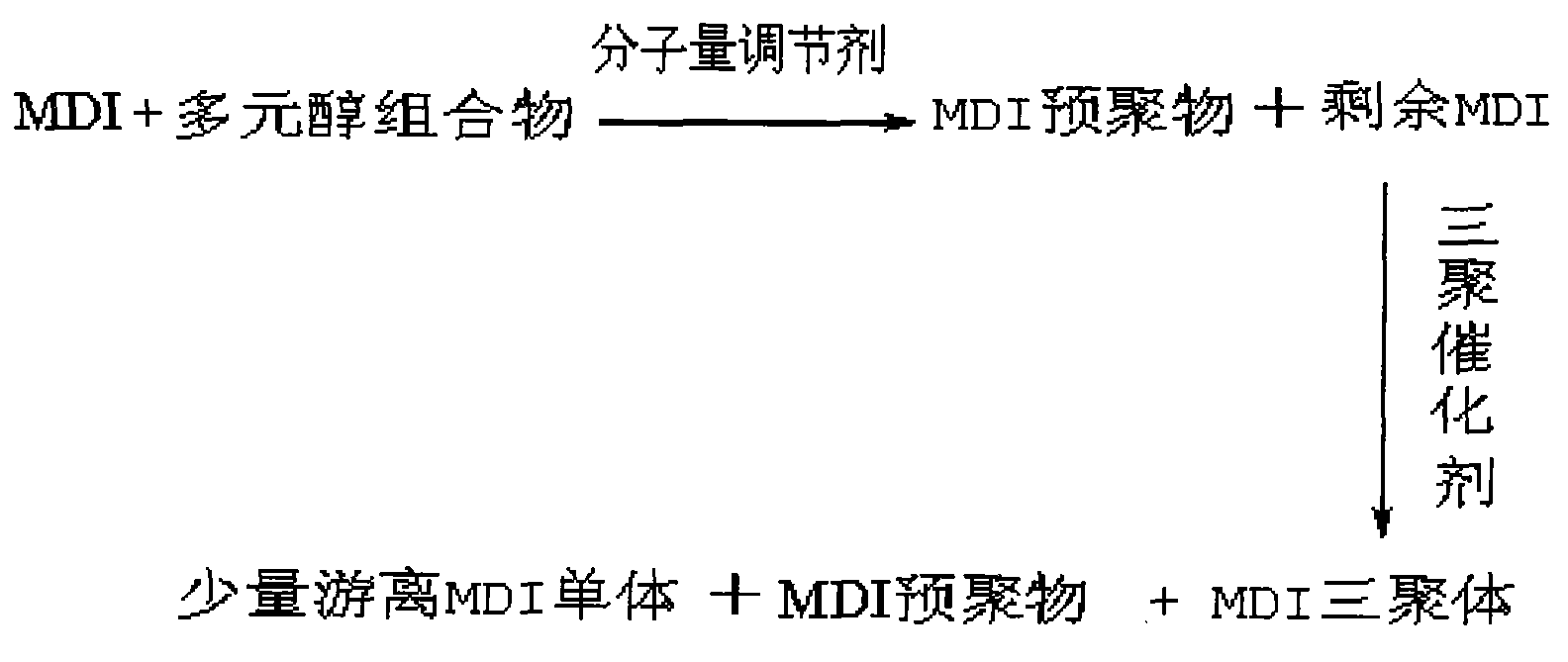

The invention discloses a polyurethane firming agent with low free MDI monomers and a method for preparing the same. The invention solves the problems that the prior art has complex MDI polyurethane firming agent preparation process and high equipment investment. The technical proposal comprises the following steps that: the step one, a molecular weight modifying agent is added into a compositionof MDI and polylol; prepolymerization reaction is carried out in a solvent, wherein, the equivalent proportion of NCO to OH is 3-5 to 1; and the adding amount of the molecular weight modifying agent is 1 to 1.5 percent of the MDI mass; step two, after the prepolymerization reaction is finished, a trimeric catalyzer is added into the solvent for trimerization reaction; the adding amount of the trimeric catalyzer is 0.1 to 0.3 percent of the residual MDI mass theoretically after the reaction in the step one; after the trimerization reaction is finished, a polymerization inhibitor is added into the solvent to terminate the reaction. The process method has low production cost and simple process equipment; the prepared firming agent has stable storage, low toxicity and performances which can meet various requirements of the firming agent of sizing agent for packing a composite membrane; when the solid content is 75 percent, the content of free MDI monomers is less than 2 percent of the firming agent mass.

Description

Polyurethane curing agent with low free MDI monomer and preparation method thereof technical field The invention relates to a polyurethane curing agent used in adhesives for solvent-based packaging composite films, in particular to a polyurethane curing agent with low free MDI monomer. Background technique The food flexible packaging made of composite film material is suitable for people's daily needs due to its light weight, convenience, long shelf life, sanitation, easy storage, easy disassembly and good shelf effect, and is increasingly popular. The properties of these composites depend not only on the selected films but also on the properties of the adhesives used to bond the different film composites together. Usually this type of adhesive includes a main agent and a curing agent. Currently, the commonly used curing agent is a prepolymer of polyols such as toluene diisocyanate (TDI) and trimethylolpropane. Toluene diisocyanate monomer is a colorless transparent liqui...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08G18/10C08G18/09C08G18/76C08G18/38C09J175/04

Inventor 王培鹏肖玉新周冬春

Owner 武汉仕全兴新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com