External cross-linking agent for waterborne polyurethane and preparation method and application of external cross-linking agent

A technology of water-based polyurethane and external linking agent, applied in the field of coatings, can solve the problems of reducing -NCO concentration, yellowing of polyurethane color, limited hydrophilicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

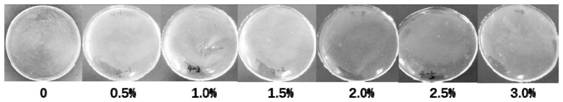

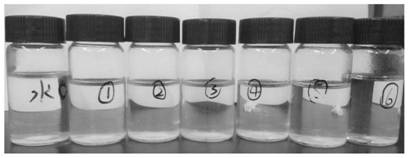

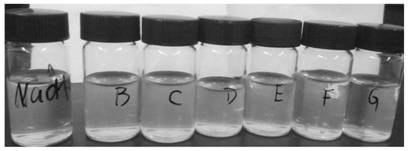

Examples

Embodiment 1

[0052] Add 0.25mol of N-methylimidazole, 0.22mol of monochlorodiethylene glycol, and 50ml of acetonitrile into the three-necked flask. The reaction was carried out at 80°C under nitrogen protection for 96 hours, and the system turned into a light yellow liquid after the reaction was stopped. Wash with acetone, ethyl acetate and ether, respectively. Vacuum dry after several washes. The product was obtained, sealed and preserved (the structure is shown below):

[0053]

[0054] According to the -NCO / -OH molar ratio of 50:1, weigh the imidazolium ionic liquid modified hydroxyl-terminated polyether and HDI trimer prepared above; add the modified polyether into a clean and dry three-necked bottle, and install the stirrer And thermometer, and nitrogen protection, add HDI trimer, stir evenly, add polyether and polyisocyanate total mass 0.02% stannous octoate, heat (heating rate ≤ 5 ℃ / min), heat up to 60 ℃, keep warm 2h, then keep warm for 0.5h, cool to below 40°C, add appropr...

Embodiment 2

[0057] Add 0.25 mol of N-methylimidazole, 0.21 mol of monobrominated polyethylene glycol (M=300), and 100 ml of acetonitrile into the three-necked flask. The reaction was carried out at 80° C. under nitrogen protection for 96 hours, and the system turned into a light yellow liquid after the reaction was stopped. Wash with acetone, ethyl acetate and ether, respectively. After washing several times, vacuum-dry to obtain the product, which is sealed and stored (the structure is shown below):

[0058] (n=5)

[0059] According to the -NCO / -OH molar ratio of 20:1, weigh the imidazolium ionic liquid modified hydroxyl-terminated polyether and HDI biuret prepared above, respectively, add the modified polyether into a clean and dry three-necked bottle, and install the stirrer And thermometer, and nitrogen protection, add HDI biuret, stir evenly, add polyether and polyisocyanate total mass 0.05% stannous octoate, heat (heating rate ≤ 5°C / min), raise the temperature to 80°C, keep war...

Embodiment 3

[0062] Add 0.25 mol of N-methylimidazole, 0.2 mol of monochlorinated polyethylene glycol (M=400), and 100 ml of acetonitrile into the three-necked flask. The reaction was carried out at 80° C. under nitrogen protection for 96 hours, and the system turned into a light yellow liquid after the reaction was stopped. Wash with acetone, ethyl acetate and ether, respectively. After washing several times, vacuum-dry to obtain the product, which is sealed and stored (the structure is shown below):

[0063] (n=8)

[0064] According to the -NCO / -OH molar ratio of 60:1, weigh the imidazole ionic liquid modified hydroxyl-terminated polyether and HDI trimer prepared above, respectively, add the modified polyether into a clean and dry three-necked bottle, and install the stirrer And thermometer, and nitrogen protection, add HDI trimer, stir evenly, add polyether and polyisocyanate total mass of 0.1% dibutyltin dilaurate, heat (heating rate ≤ 5 ℃ / min), the temperature rises to 70 ℃ , k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com