A kind of polyurethane prepolymer and preparation method thereof

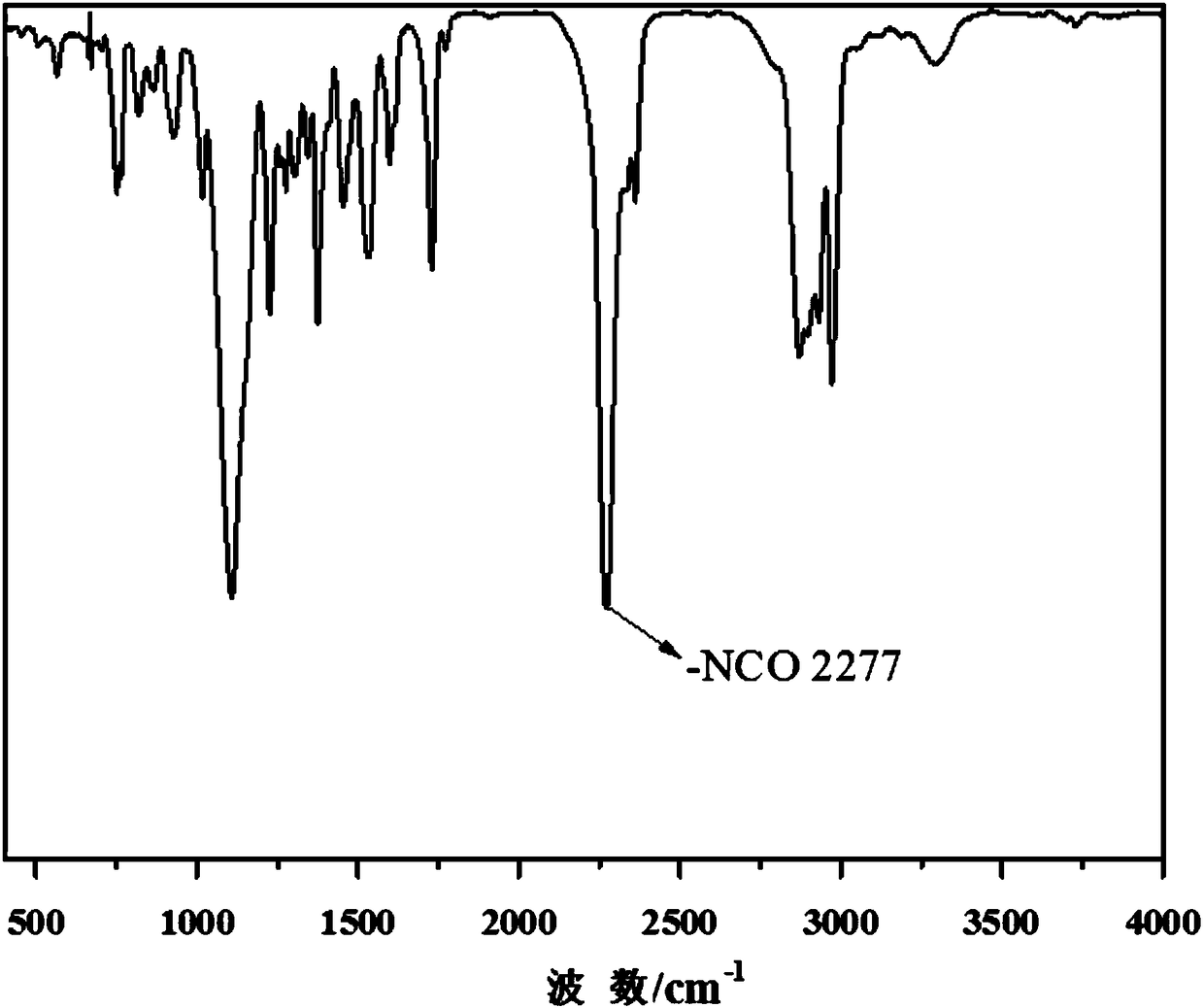

A polyurethane prepolymer and polyester polyol technology, applied in the field of polyurethane prepolymer and its preparation, can solve the problems of short storage period and poor stability, and achieve the effect of long storage period, high stability and high NCO content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The weight ratio of each component in the raw material is as follows:

[0053] Polyethylene glycol (polyether polyol): 18.5 parts by weight, number average molecular weight Mn=1500;

[0054] Polyethylene adipate (polyester polyol): 40 parts by weight, number average molecular weight Mn=2500;

[0055] Isophorone diisocyanate IPDI (isocyanate): 48 parts by weight;

[0056] Di-n-butyltin dilaurate (catalyst): 0.01 parts by weight

[0057] Diethanolamine (chain extender): 0.82 parts by weight;

[0058] Anti-yellowing agent 8168 and modified silicone oil (auxiliary: anti-yellowing agent and defoamer at a weight ratio of 1:1): 0.01 parts by weight.

[0059] Concrete preparation steps are as follows:

[0060] Add 3.7g of polyethylene glycol (PEG-1500) and 8g of adipate (Mn=2500) into a dry three-necked flask, install a vacuum distillation device, raise the temperature to 85°C, and distill under reduced pressure to remove water for 2 hours, try to remove trace water in...

Embodiment 2

[0065] The weight ratio of each component in the raw material is as follows:

[0066] Polypropylene glycol (polyether polyol): 16 parts by weight, number average molecular weight Mn=3000;

[0067] Polypropylene adipate (polyester polyol): 45 parts by weight, number average molecular weight Mn=3000;

[0068] Hexamethylene diisocyanate HDI (isocyanate): 38 parts by weight;

[0069] Two (2-dimethylaminoethyl) ether (catalyst): 0.05 parts by weight;

[0070] N-methyldiethanolamine (chain extender): 0.94 parts by weight;

[0071] Anti-yellowing agent 8168 and modified silicone oil (auxiliary: anti-yellowing agent and defoamer at a weight ratio of 1:1): 0.01 parts by weight.

[0072] Concrete preparation steps are as follows:

[0073] Add 3.2g of polypropylene glycol (PPG-3000) and 9g of adipate (Mn=3000) into a dry three-necked flask, install a vacuum distillation device, raise the temperature to 95°C, and distill and remove water under reduced pressure under mechanical sti...

Embodiment 3

[0078] The weight ratio of each component in the raw material is as follows:

[0079] Polyethylene glycol (polyether polyol): 10 parts by weight, number average molecular weight Mn=600;

[0080] Polyethylene adipate (polyester polyol): 44 parts by weight, number average molecular weight Mn=2000;

[0081] Isophorone diisocyanate IPDI (fatty isocyanate): 35 parts by weight;

[0082] Toluene diisocyanate TDI (aromatic isocyanate): 10.4 parts by weight;

[0083] Di-n-butyltin dilaurate (catalyst): 0.09 parts by weight;

[0084] Diethanolamine (chain extender): 0.5 parts by weight;

[0085] Anti-yellowing agent 8168 and modified silicone oil (auxiliary: anti-yellowing agent and defoamer at a weight ratio of 1:1): 0.01 parts by weight.

[0086] Concrete preparation steps are as follows:

[0087] Add 2g of polyethylene glycol (PEG-3000) and 8.8g of polycarbonate (Mn=2000) into a dry three-necked flask, install a vacuum distillation device, raise the temperature to 80°C to 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com