Silane hybrid quaternary ammonium salt modified polyisocyanate curing agent and preparation method thereof

A polyisocyanate, quaternary ammonium salt technology, applied in chemical instruments and methods, organic chemistry, paints containing biocides, etc., can solve the problems of coating film gloss, poor transparency, low NCO content, and high reaction temperature. The effect of good water dispersibility, high NCO content and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

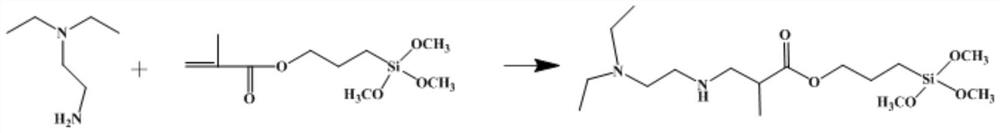

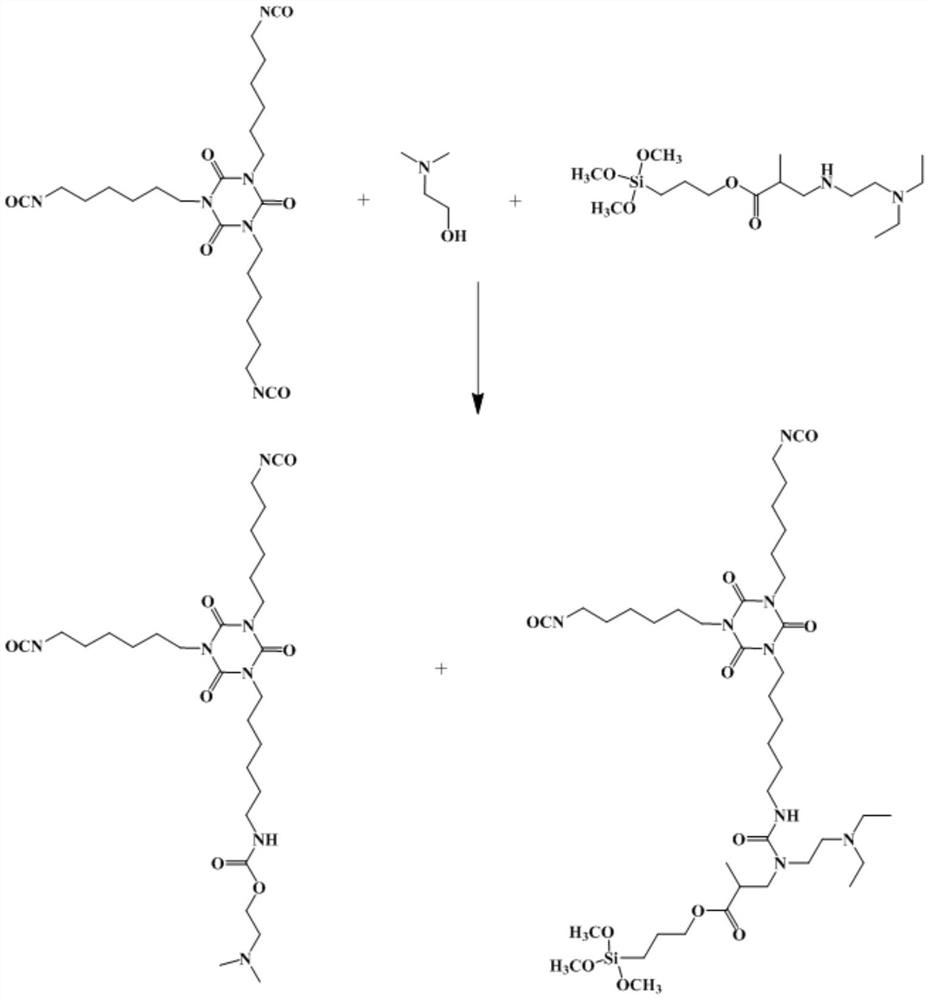

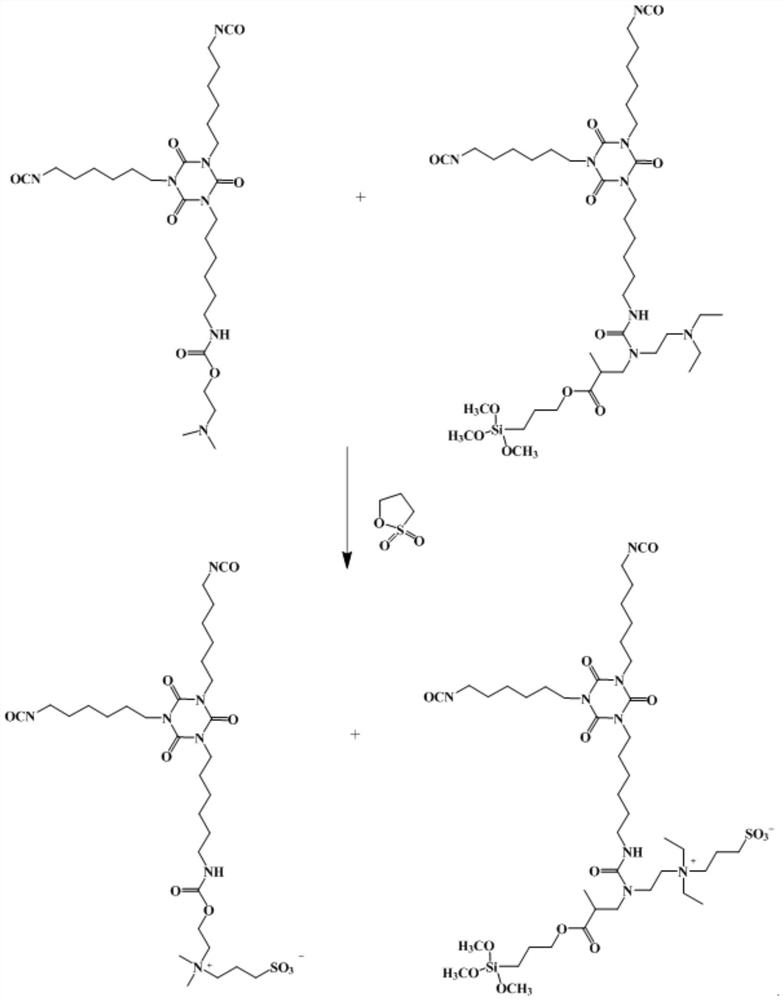

Method used

Image

Examples

Embodiment 1

[0037] 185g of HDI trimer was added to the tank equipped with mechanical stirring, reflux tube, constant pressure separatory funnel and N 2 Add a small amount of PMA to the four-neck round-bottomed flask at the import and export points to adjust the viscosity. Under nitrogen atmosphere protection, slowly add 3g of N,N-dimethylethanolamine and 6g of silane coupling agent dropwise within 10 minutes. Slowly raise the temperature to 50°C, react for 2 hours under the action of low-speed stirring until the NCO mass content of the system reaches the theoretical value, then add diethyl sulfate to terminate the reaction, keep the temperature for 1 hour, cool down to room temperature, and slowly add 6g dropwise within 5 minutes The 1,3-sultone, after the dropwise addition, was reacted at 50°C for 2.5 hours. The temperature was lowered, and the reaction solvent was removed by thin film distillation to obtain a light yellow transparent viscous liquid and a silane hybrid quaternary ammoniu...

Embodiment 2

[0040] Add 185g of hexamethylene diisocyanate (HDI) to the 2 A small amount of dimethyl sulfoxide was added to adjust the viscosity of the four-necked round-bottomed flask at the import and export, and under nitrogen atmosphere protection, 3 g of N-methyldiethanolamine and 6 g of silane coupling agent were slowly added dropwise within 15 minutes. Slowly raise the temperature to 40°C, react for 2 hours under the action of low-speed stirring until the NCO mass content of the system reaches the theoretical value, then add methyl toluenesulfonate to terminate the reaction, keep warm for 1 hour, cool down to room temperature, and slowly add dropwise within 4 minutes 6 g of propenyl-1,3-sultone was added dropwise and reacted at 60° C. for 2 hours. The temperature was lowered, and the reaction solvent was removed by thin film distillation to obtain a light yellow transparent viscous liquid and a silane hybrid quaternary ammonium salt modified polyisocyanate curing agent with an NCO m...

Embodiment 3

[0043] 185g of isophorone diisocyanate (IPDI) was added to the 2 A small amount of N,N-dimethylacetamide was added to the four-neck round bottom flask at the import and export to adjust the viscosity, under nitrogen atmosphere protection, 3g of triethanolamine and 6g of silane coupling agent were slowly added dropwise within 20 minutes. Slowly raise the temperature to 60°C, react for 2 hours under the action of low-speed stirring until the NCO mass content of the system reaches the theoretical value, then add dimethyl sulfate to terminate the reaction, keep the temperature for 1 hour, cool down to room temperature, and slowly add 6g dropwise within 6 minutes After the 1.4-butane sultone was added dropwise, it was reacted at 40°C for 3 hours. The temperature was lowered, and the reaction solvent was removed by thin film distillation to obtain a light yellow transparent viscous liquid and a silane hybrid quaternary ammonium salt-modified polyisocyanate curing agent with an NCO m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com