Polyurethane material for making chicken manure scraper of farm

A polyurethane material and farm technology, applied in the field of polyurethane materials, can solve problems such as lamination, and achieve the effects of long life, good wear resistance and good friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

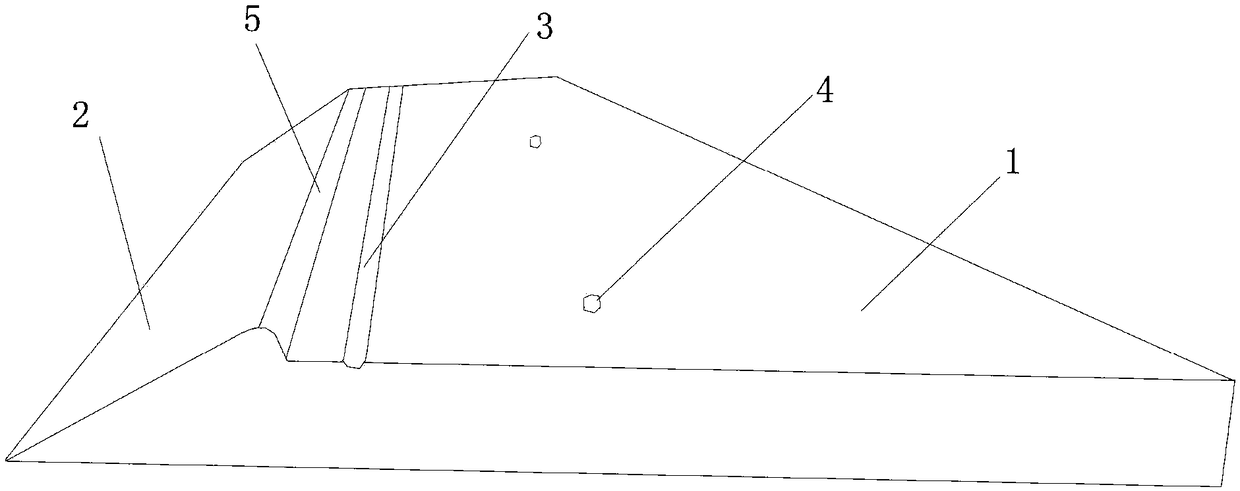

Image

Examples

Embodiment 1

[0021] The scraper material is made of the following raw materials by weight: polytetrahydrofuran glycol PTMG is added with isocyanate TDI to make the -NCO content of the synthesized prepolymer 6.8%; the prepolymer is added with chain extender MOCA; PTMG, TDI The mass ratio is 2.7:1; the mass ratio of prepolymer and MOCA is 100:19.7; the preparation method is: dehydration of PTMG at 100-120℃, vacuum degree of 5-10 Torr for 1-2 hours, water content <0.05%, Cool the dehydrated PTMG to 50-70°C. After the system is naturally heated for 30-40 minutes, mix the PTMG and TDI in the mixing head at 75-85°C, keep it for 2-3 hours, and defoam under 5-10 Torr vacuum. 40min, the speed of 0.5kg / min-15kg / min is poured into the mold, the mold temperature is controlled at 100°C, the mold is demolded 60min after gelation, and then the demolded material is put into the vulcanization box, and the temperature is controlled at 110~120°C to vulcanize 10~12h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com