A bus finish paint with excellent pollution resistance and low dust contamination rate and preparation method thereof

A pollution resistance, bus technology, applied in coatings, polyester coatings, polyurea/polyurethane coatings, etc., can solve the problems of paint pollution resistance, unsatisfactory dust rate, etc., and achieve excellent outdoor aging resistance, Effect of discoloration and peeling inhibition and weather resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

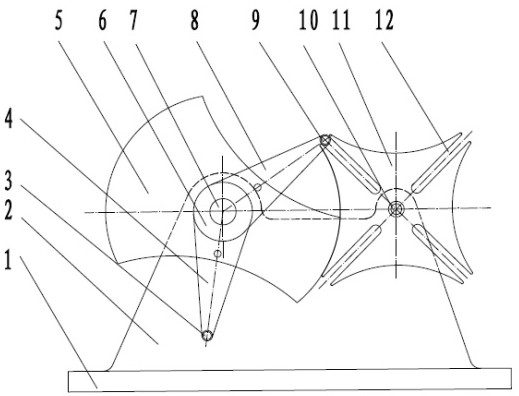

Image

Examples

Embodiment 1

[0054] A bus finish paint with excellent pollution resistance and low dust contamination rate and a preparation method thereof, the method comprising the following process steps:

[0055] For component A, prepare raw materials according to the following components and percentages:

[0056] Resin A, 35-45, is specifically a hydroxy acrylic resin, with a solid content of 75-80%, a hydroxyl content of 3.5-4.5%, high solid and low viscosity, providing excellent gloss and distinctness of image; outstanding weather resistance;

[0057] Resin B, 15-20, specifically a hydroxyacrylic resin for two-component automotive paint, with a glass transition temperature Tg≥60°C, providing excellent scratch resistance, stain resistance and drying performance, and extremely high hardness;

[0058] Wetting and dispersing agent A, 4-8, which is specifically a high-molecular-weight block copolymer containing pigment-affinity groups, has broad compatibility, and can be used to stably disperse various ...

Embodiment 2

[0073] A method for preparing a bus finish paint with excellent pollution resistance and low dust contamination rate, the method comprises the following process steps:

[0074] Component A, prepare raw materials according to the following components and percentages:

[0075] Resin A, 50-60, is specifically a hydroxyacrylic resin, with a hydroxyl content of 3.5-4.5%, a solid content of 75-80%, high solid and low viscosity, providing excellent gloss and vividness; outstanding weather resistance;

[0076] Resin C, 5-10, it is specifically a saturated polyester resin with a solid content of 80%, excellent appearance effect, and improves the vividness and leveling of the paint film;

[0077] Wetting and dispersing agent A, 4-8, which is specifically a high-molecular-weight block copolymer containing pigment-affinity groups, has broad compatibility, and can be used to stably disperse various pigments;

[0078] Wetting and dispersing agent B, 1-2, which is specifically a copolymer s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com