Preparation method, product and applications of highly anti-adhesive printing paste

A printing paste, high anti-sticking technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of difficult industrial stable production, complicated preparation process, difficult to unfold fabrics, etc., to improve hand feeling, smoother surface and reduce friction The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: the preparation method of the high anti-adhesive printing paste provided by the embodiment of the present invention, it comprises the following steps:

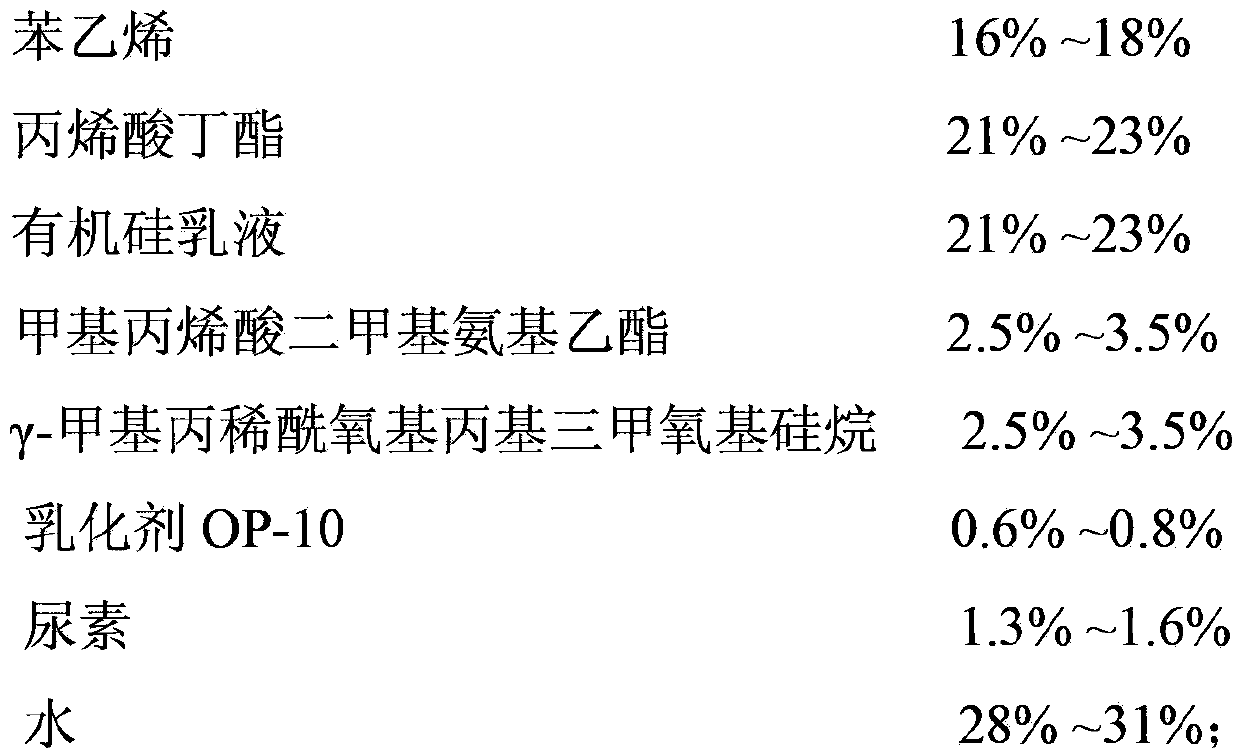

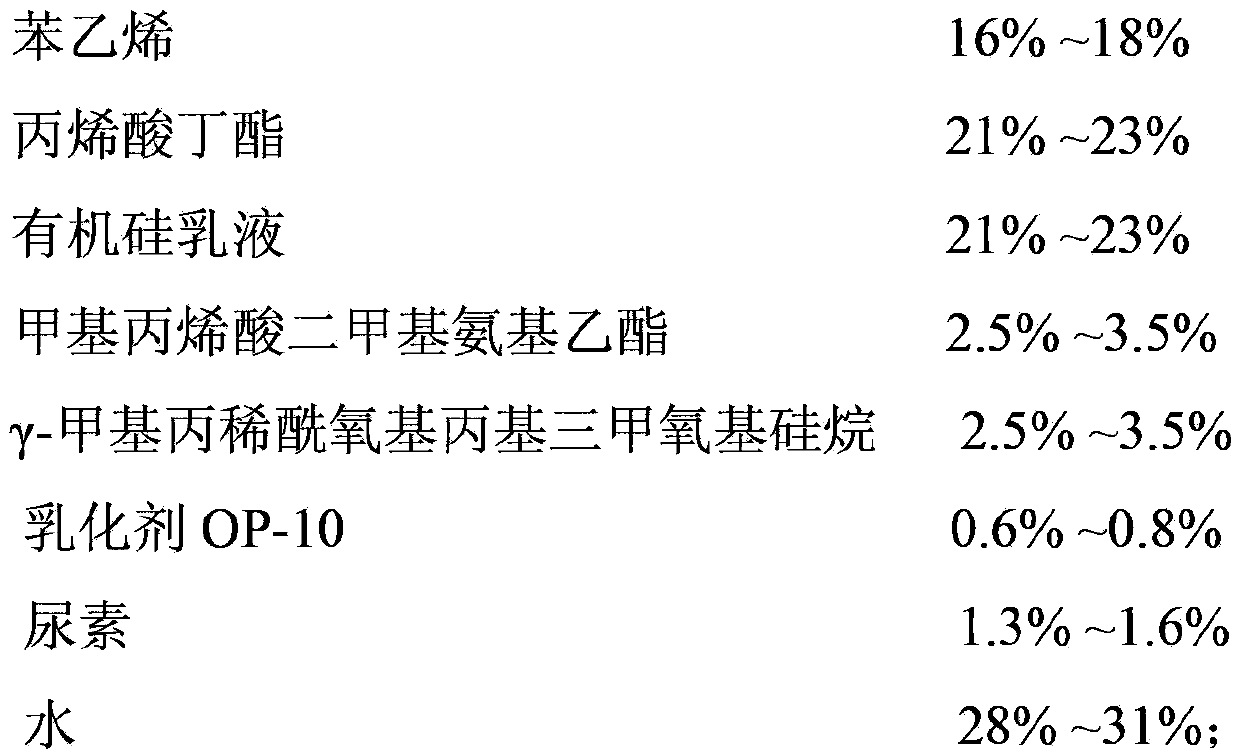

[0042] (1) Weighing: Weigh and mix the following components according to the weight ratio, and then stir evenly until milky white to obtain a non-layered emulsion A:

[0043]

[0044]

[0045] (2) Weigh the following components according to the weight ratio and mix them evenly to prepare the bottom liquid B:

[0046] Ammonia 3.5%~4.5%

[0047] Sodium bicarbonate 3.5%~4.5%

[0048] Water 91%~93%;

[0049] (3) Take the following components by weight and mix them uniformly to prepare Initiator C:

[0050] Potassium persulfate 5.5%~7.5%

[0051] Water 92.5%~94.5%;

[0052] (4) The prepared emulsion A, bottom liquid B and initiator C are subjected to semi-continuous seed polymerization reaction, and the emulsion A, bottom liquid B and initiator C are added to the reaction in a weight ratio of 5:93:2 ...

Embodiment 2

[0073] Embodiment 2: The preparation method, product and application of a kind of high anti-adhesive printing paste provided in this embodiment are basically the same as in Embodiment 1, the difference is that it is made of the following components by weight:

[0074] Weigh and mix the following components according to the weight ratio, and then stir evenly until milky white to obtain a non-layered emulsion A:

[0075]

[0076] Weigh the following components by weight and mix them uniformly to prepare bottom liquid B:

[0077] Ammonia 3.5%

[0078] Sodium bicarbonate 3.5%

[0079] water 93%

[0080] Take by weight the following components and mix homogeneously to prepare initiator C:

[0081] Potassium persulfate 5.5%

[0082] Water 94.5%

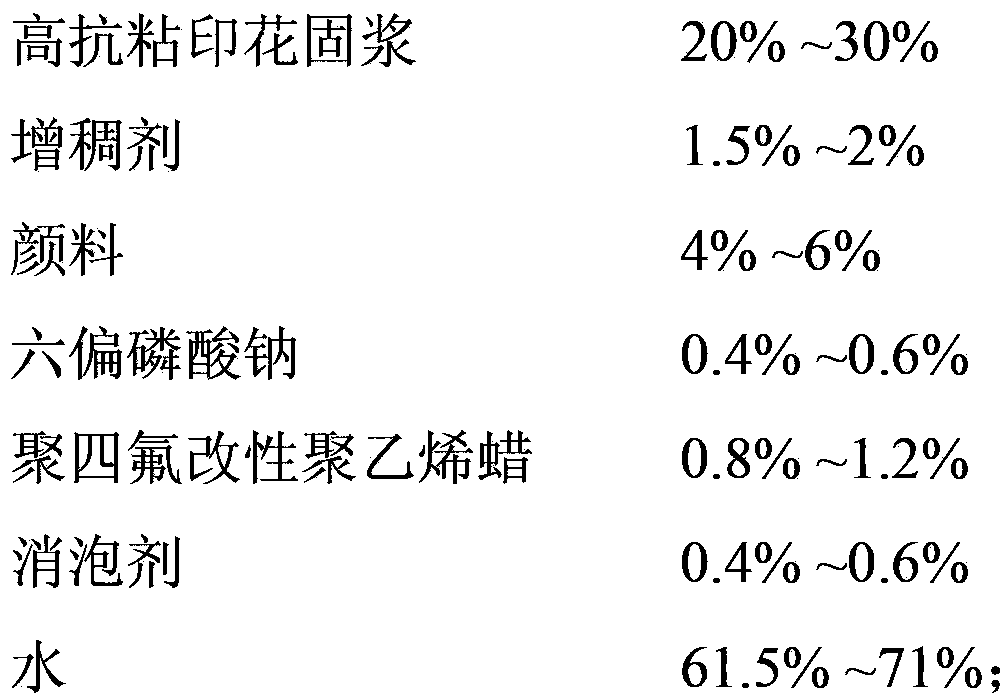

[0083] The application of a high anti-adhesive printing paste provided in this embodiment, its steps are basically the same as in Example 1, the difference is that it is made of components in the following weight ratio:

[0084] ...

Embodiment 3

[0085] Embodiment 3: The preparation method, product and application of a kind of high anti-adhesive printing paste provided in this embodiment are basically the same as Embodiment 1 and 2, the difference is that it is made of the following components by weight:

[0086] Weigh and mix the following components according to the weight ratio, and then stir evenly until milky white to obtain a non-layered emulsion A:

[0087]

[0088] Weigh the following components by weight and mix them uniformly to prepare bottom liquid B:

[0089] Ammonia 4%

[0090] Sodium bicarbonate 4%

[0091] water 92%

[0092] Take by weight the following components and mix homogeneously to prepare initiator C:

[0093] Potassium persulfate 7.5%

[0094] Water 92.5%

[0095] The application of a kind of high anti-adhesive printing paste provided by this embodiment, its steps are basically the same as those in Examples 1 and 2, the difference is that it is made of the following components by weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com