High-flatness, high-barrier, high-strength and cooking-resistant stretch film and production method thereof

A high barrier and flatness technology, applied in chemical instruments and methods, layered products, flat products, etc., can solve problems that affect product information reading, be easily restricted by thickness, and affect the appearance of aesthetics, so as to improve the aesthetics of packaging , the cooling effect is uniform, and the finished product is flat and beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

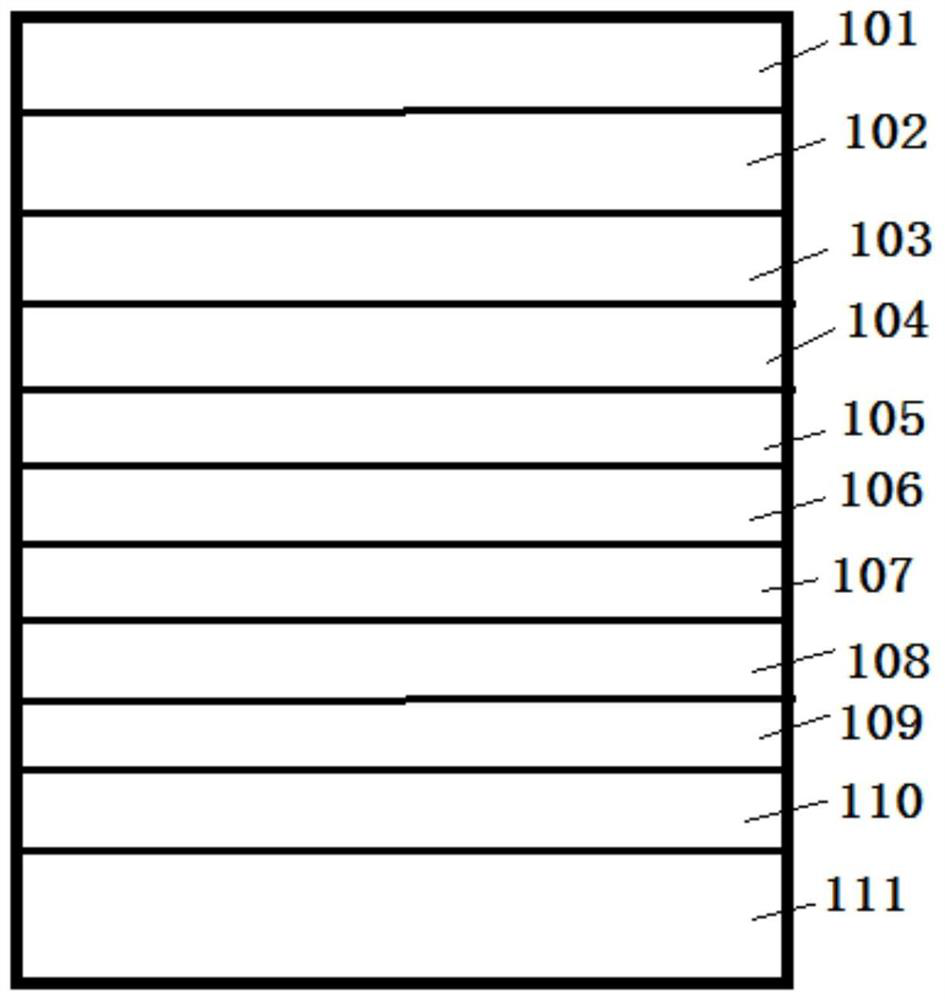

[0046] A high-flatness, high-barrier, high-strength, retort-resistant stretch film, such as figure 1 as shown, figure 1 It is a structural schematic diagram of the high-flatness, high-barrier, high-strength retort-resistant stretched film of the present invention. From top to bottom are the outer layer 101, the first outer layer 102, the second outer layer 103, the first adhesive layer 104, the first PA layer 105, the high barrier layer 106, the second PA layer 107, the second The adhesive layer 108, the second heat-sealing layer 109, the first heat-sealing layer 110, and the heat-sealing layer 111 are all made of PP , the first adhesive layer 104 and the second adhesive layer 108 are made of maleic anhydride-modified polyethylene resin, and the first PA layer 105 and the second PA layer 107 are made of PA, so The raw material of the high barrier layer 106 is EVOH, the raw materials of the second heat-sealing layer 109, the first heat-sealing layer 110, and the heat-sealing ...

Embodiment 2

[0055] A high-flatness, high-barrier, high-strength, retort-resistant stretched film, from top to bottom is the outer layer 101, the first outer layer 102, the second outer layer 103, the first adhesive layer 104, and the first PA layer 105, high barrier layer 106, second PA layer 107, second adhesive layer 108, second heat seal layer 109, first heat seal layer 110, heat seal layer 111, the outer surface layer 101, first time The raw materials of the outer layer 102 and the second outer layer 103 are all PP, and the first adhesive layer 104 and the second adhesive layer 108 are made of maleic anhydride-modified polyethylene resin. The first PA The raw materials of the layer 105 and the second PA layer 107 are PA, the raw materials of the high barrier layer 106 are EVOH, and the raw materials of the second heat-seal layer 109, the first heat-seal layer 110, and the heat-seal layer 111 are all Using PE, the product structure is PP / PP / PP / TIE / PA / EVOH / PA / TIE / PE / PE / PE.

[0056] The...

Embodiment 3

[0063] A high-flatness, high-barrier, high-strength, retort-resistant stretched film, from top to bottom is the outer layer 101, the first outer layer 102, the second outer layer 103, the first adhesive layer 104, and the first PA layer 105, high barrier layer 106, second PA layer 107, second adhesive layer 108, second heat seal layer 109, first heat seal layer 110, heat seal layer 111, the outer surface layer 101, first time The raw materials of the outer layer 102 and the second outer layer 103 are all PP, and the first adhesive layer 104 and the second adhesive layer 108 are made of maleic anhydride-modified polyethylene resin. The first PA The raw materials of the layer 105 and the second PA layer 107 are PA, the raw materials of the high barrier layer 106 are EVOH, and the raw materials of the second heat-seal layer 109, the first heat-seal layer 110, and the heat-seal layer 111 are all Using PE, the product structure is PP / PP / PP / TIE / PA / EVOH / PA / TIE / PE / PE / PE.

[0064] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com