Dendritic copper electrode with hydrophobic surface and preparation method and application thereof

A crystalline copper and dendritic technology, applied in the field of electrocatalysis, can solve the problems of limiting the stability of electrocatalytic CO, reducing the intrinsic conductivity of electrodes, reducing the number of three-phase interfaces, etc., and achieving excellent electrocatalytic CO2 reduction activity, The effect of enhancing ion concentration and interfacial electric field, and increasing carbon-carbon coupling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing a surface-hydrophobic dendritic copper electrode, comprising the following steps:

[0039] Copper salt solution is used as the electroplating solution, the gas diffusion layer material is used as the working electrode, and the Ag / AgCl electrode is used as the reference electrode, and constant potential deposition is carried out to obtain a dendritic copper electrode with a hydrophobic surface;

[0040] The potential of the constant potential deposition relative to the Ag / AgCl reference electrode is -0.1--0.7V; the time of the constant potential deposition is 100-700s.

[0041] In the preparation method provided by the present invention, the electroplating solution is first prepared, and the electroplating solution is an aqueous copper salt solution, and the copper salt is preferably a soluble inorganic copper salt, including but not limited to one of copper sulfate, copper chloride and copper nitrate one or more...

Embodiment 1

[0054] Weigh 5 mmol of copper sulfate and dissolve it in 50 mL of deionized water, and use dilute sulfuric acid to adjust the pH of the solution to 2 as the electroplating solution. Immerse the surface-hydrophilized gas diffusion carbon paper, Ag / AgCl (saturated KCl) reference electrode and carbon rod in the electroplating solution, and apply a bias of -0.7V (vs.Ag / AgCl) to the cathode for constant potential deposition , the deposition time is 700s, and the deposition area is 1cm×1cm. After the deposition, the surface of the electrode was rinsed three times with deionized water and twice with ethanol, and then dried in vacuum for 6 hours to obtain a dendritic copper electrode with a hydrophobic surface. The copper layer deposited on the surface of the copper electrode had a thickness of about 17 μm. The amount is 2.75mg / cm 2 .

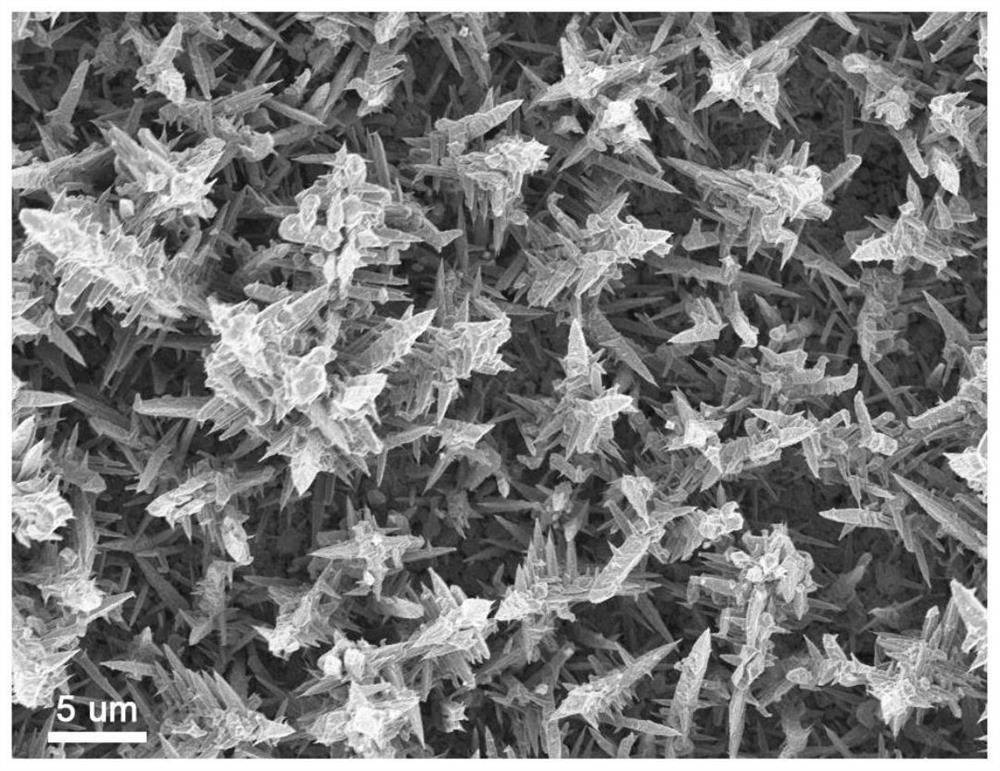

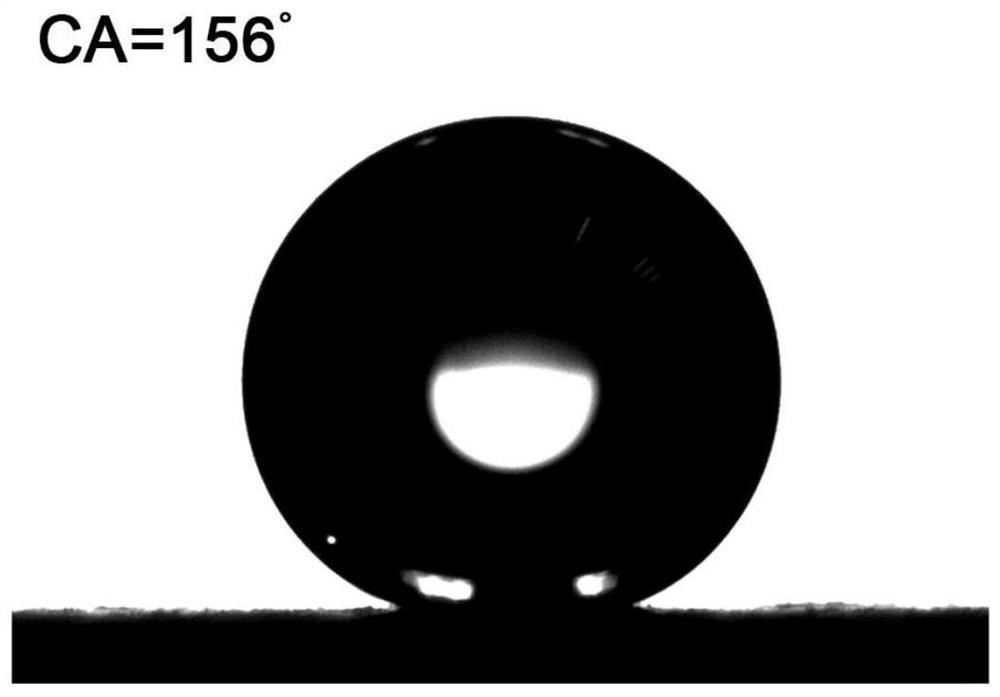

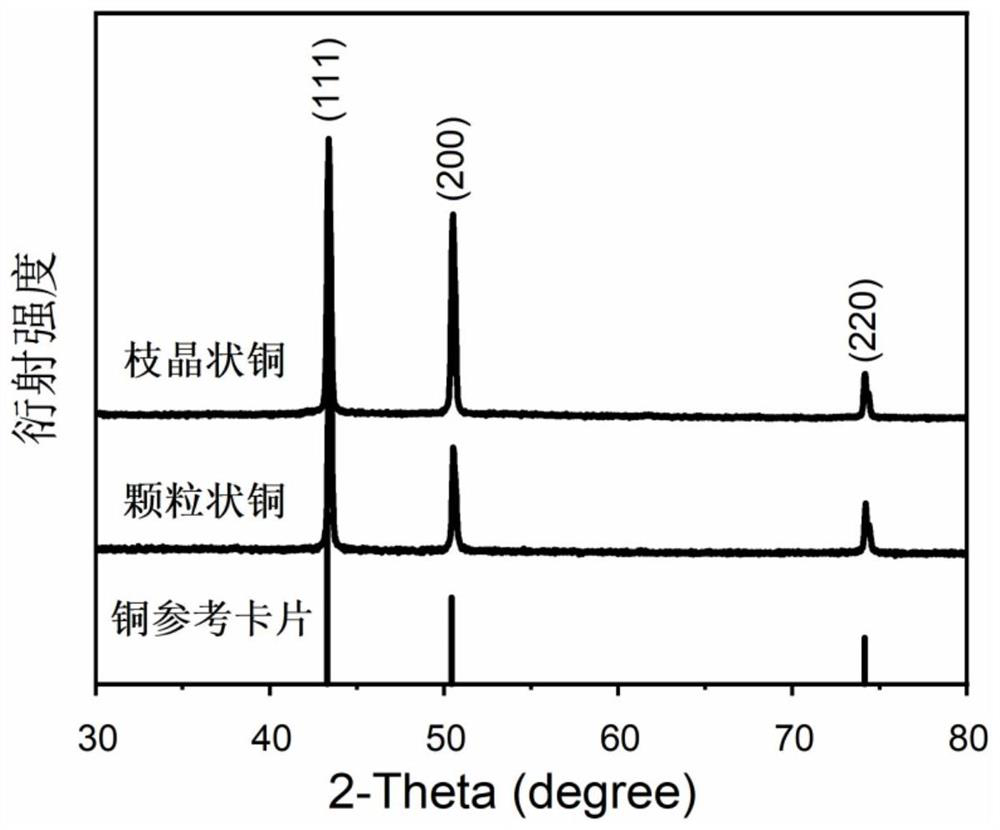

[0055] Utilize scanning electron microscope to carry out morphology observation to the copper electrode prepared in this embodiment, obtain its scan...

Embodiment 2

[0059] Weigh 5 mmol of copper sulfate and dissolve it in 50 mL of deionized water, and use dilute sulfuric acid to adjust the pH of the solution to 2 as the electroplating solution. Immerse the surface-hydrophilized gas diffusion carbon paper, Ag / AgCl (saturated KCl) reference electrode and carbon rod in the electroplating solution, and apply a bias of -0.7V (vs.Ag / AgCl) to the cathode for constant potential deposition , the deposition time is 100s, and the deposition area is 1cm×1cm. After the deposition, the surface of the electrode was rinsed 3 times with deionized water, 2 times with ethanol, and then dried in vacuum for 6 hours to obtain a dendritic copper electrode with a hydrophobic surface. The copper layer deposited on the surface of the copper electrode had a thickness of about 2.5 μm. The deposition amount is 0.40mg / cm 2 .

[0060] Utilize scanning electron microscope to analyze the copper electrode that present embodiment prepares, obtain its scanning electron mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com