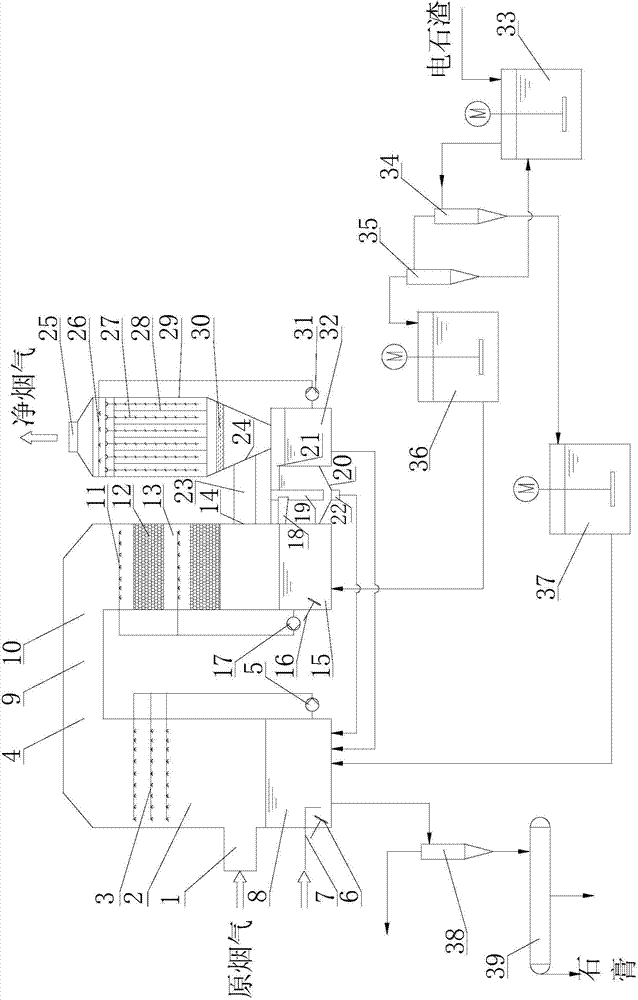

Flue gas deep desulfurization and dust removal device and method by use of carbide slag-gypsum method

A technology of deep desulfurization and dust removal device, which is applied in separation methods, chemical instruments and methods, external electrostatic separators, etc., can solve the problems of low desulfurization efficiency and substandard flue gas emission, and achieves environmental protection and economic benefits. The effect of taking up space and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The coal-fired flue gas from the boiler bag dust removal, the flue gas volume is 500-200m 3 / h, the sulfur dioxide concentration at the inlet of the primary desulfurization flue gas is 3000mg / Nm 3 , smoke concentration 192mg / m 3 , Flue gas temperature 135 ℃. After passing through the calcium carbide slag-gypsum flue gas deep desulfurization and dust removal device, the sulfur dioxide concentration at the outlet of the wet electric flue gas is 14mg / Nm 3 , the desulfurization efficiency reaches 99.5%, and the dust concentration is 8mg / Nm 3 , PM2.5 lower than 15ug / Nm 3 , flue gas temperature 46 ℃.

Embodiment 2

[0064] The coal-fired flue gas from the boiler bag dust removal, the flue gas volume is 270100m 3 / h, the sulfur dioxide concentration at the inlet of the primary desulfurization flue gas is 2670mg / Nm 3 , soot concentration 174mg / m 3 , Flue gas temperature 130 ℃. After passing through the calcium carbide slag-gypsum flue gas deep desulfurization and dust removal device, the sulfur dioxide concentration at the outlet of the wet electric flue gas is 12mg / Nm 3 , the desulfurization efficiency reaches 99.5%, the smoke is not detected, and the PM2.5 is lower than 15ug / Nm 3 , flue gas temperature 44 ℃.

Embodiment 3

[0066] The coal-fired flue gas from the boiler bag dust removal, the flue gas volume is 441253m 3 / h, the sulfur dioxide concentration at the inlet of the primary desulfurization flue gas is 3640mg / Nm 3 , soot concentration 192mg / m 3 , Flue gas temperature 140 ℃. After the calcium carbide slag-gypsum flue gas deep desulfurization and dust removal device, the sulfur dioxide concentration at the outlet of the wet electric flue gas is 15mg / Nm 3 , the desulfurization efficiency is up to 99.5%, and the dust is 7mg / Nm 3 , PM2.5 lower than 15ug / Nm 3 , flue gas temperature 52 ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com