Aluminum alloy rare earth passivating liquid taking chlorine salt as accelerator and use method thereof

An aluminum alloy and passivation solution technology, which is applied in the field of passivation solution where the accelerator is chloride salt, can solve the problems affecting process stability and industrial application, and achieves rapid dissolution rate, simple operation and excellent corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

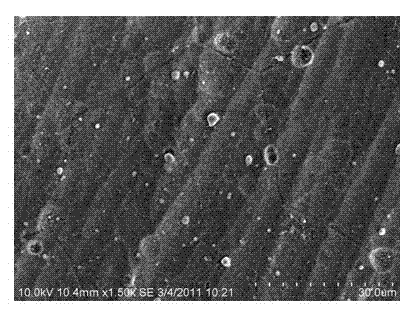

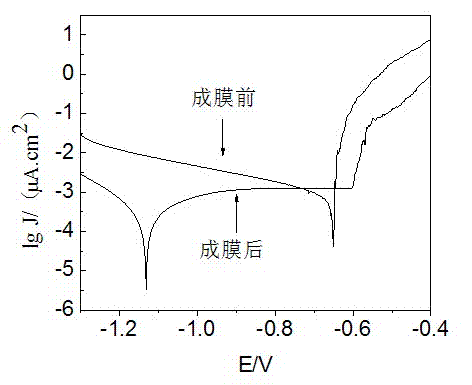

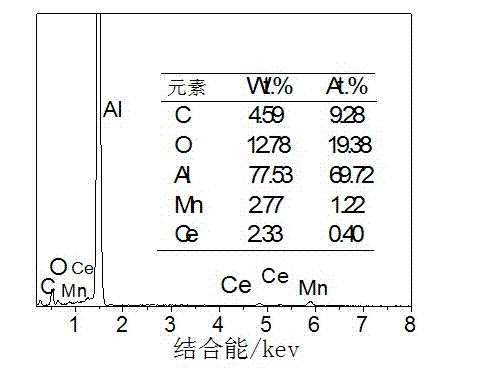

[0031] Embodiment 1: Rare earth conversion treatment on the surface of 6063 aluminum alloy profile (1.5mm)

[0032] The rare earth chemical conversion treatment method on the surface of aluminum alloy comprises the following steps:

[0033] (1) Pretreatment: (a) Cut 5×5cm from 6063 large-size aluminum alloy profiles (thickness 1.5mm) 25 pieces of samples were drilled, and polished with SiC water sandpaper until the surface roughness was 10 microns, and the surface dirt was cleaned with tap water and dried with a blower, and the holes were connected with thin wires; (b) the weak Put the caustic alkaline solution into an ultrasonic cleaning machine, put an aluminum alloy test piece, ultrasonically clean it for 8 minutes, and then clean it with deionized water; in terms of weight to volume ratio, the weak caustic alkaline solution is 8g / L anhydrous carbonic acid Sodium, 6g / L sodium silicate to prepare deionized aqueous solution; (c) immerse the test piece in the alkaline solut...

Embodiment 2

[0037] Embodiment 2: Rare earth conversion treatment on the surface of 6063 aluminum alloy profile (1.5mm)

[0038] The rare earth chemical conversion treatment method on the surface of aluminum alloy comprises the following steps:

[0039] (1) Pretreatment: (a) Cut 3×3cm from 6063 large-size aluminum alloy profiles (thickness 1.5mm) 2 5 pieces of samples were drilled, and polished with SiC water sandpaper to a surface roughness of 0.01 micron, and the surface dirt was cleaned with tap water and dried with a blower, and connected with thin wires at the punched places; (b) the weak Put the caustic alkaline solution into an ultrasonic cleaning machine, put an aluminum alloy test piece, ultrasonically clean it for 4 minutes, and then clean it with deionized water; by weight to volume ratio, the weak caustic alkaline solution is 10g / L anhydrous carbonic acid Sodium, 15g / L sodium silicate to prepare a deionized aqueous solution; (c) Put the test piece into the alkaline solution ...

Embodiment 3

[0043] Embodiment 3: Rare earth conversion treatment on the surface of 6063 aluminum alloy profile (1.5mm)

[0044] The rare earth chemical conversion treatment method on the surface of aluminum alloy comprises the following steps:

[0045] (1) Pretreatment: (a) Mechanically polish the surface of the aluminum alloy to control the surface roughness at 8 microns; (b) Put the weak corrosion alkaline solution into the ultrasonic cleaning machine, put the aluminum alloy test piece, Ultrasonic cleaning for 10 minutes, and then cleaning with deionized water; according to the weight to volume ratio, the weak corrosion alkaline solution is 8g / L anhydrous sodium carbonate and 5g / L sodium silicate to prepare a deionized aqueous solution; (c) Put the test piece into the alkaline solution and soak for 2 minutes, and then rinse it with deionized water; the concentration of each component in the alkaline solution is 8g / L sodium hydroxide, 6g / L anhydrous Sodium carbonate; (d) Immerse the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current density | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com