Preparation method of monocrystal-like lithium nickel cobalt manganate

A technology of nickel-cobalt-manganese lithium manganese oxide and nickel-cobalt-manganese oxide, which is applied in the field of preparation of quasi-single crystal nickel-cobalt manganese oxide lithium, can solve the problems of material electrical performance degradation, reduce compaction density, side reactions, etc., and achieve improved order degree , to avoid the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083] In some embodiments, the preparation method of the single-crystal nickel-cobalt-like lithium manganate cathode material includes:

[0084] Step 1: Solution Preparation

[0085] The soluble metal salts of nickel, cobalt and manganese are configured into a transition metal salt solution with a total molar concentration of nickel, cobalt and manganese of 1-2 mol / L;

[0086] adding the complexing agent to the transition metal salt solution prepared above to obtain the transition metal salt solution adding the complexing agent;

[0087] The electrolyte and the inorganic base are prepared into an adjustment solution with a pH value of 13-14;

[0088] The second step: preparation of nickel cobalt manganese metal precipitate

[0089]The various solutions prepared in the first step are simultaneously and continuously pumped into the three-port reaction kettle through different feeding pipes, and when feeding, ensure that the feeding position of the feeding pipe in the kettle f...

Embodiment 1-4

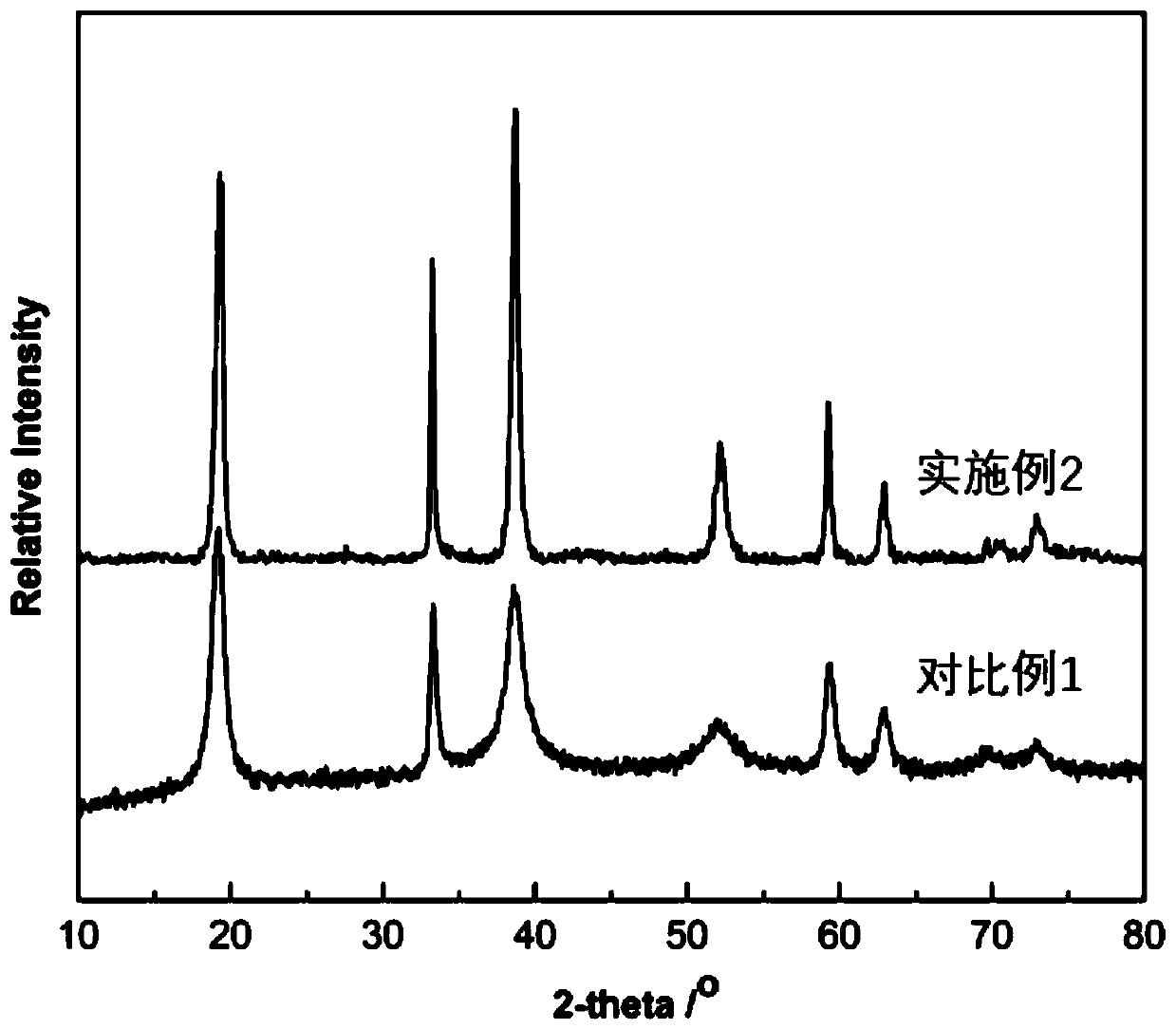

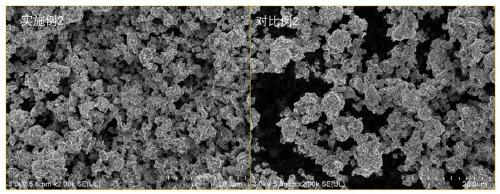

[0107] In Examples 1-4, the protective gas flow rate is different in the second step, and other operation steps are the same. The protective gas flow in Example 1 was 1 mL / min, the protective gas flow in Example 2 was 5 mL / min, the protective gas flow in Example 3 was 10 mL / min, and the protective gas flow in Example 4 was 20 mL / min, as shown in Table 1.

[0108] The specific experimental operations of each embodiment are:

[0109] Step 1: Solution Preparation

[0110] Weigh 9.6 mol of nickel nitrate hexahydrate, 0.2 mol of cobalt acetate tetrahydrate, 0.2 mol of manganese sulfate monohydrate and add them to the container, add an appropriate amount of water to make the total volume of the solution 5L, and obtain a transition metal total concentration of 2mol / L salt solution;

[0111] Take by weighing 5mol ammonium sulfate as complexing agent, join in the above-mentioned salt solution of configuration, obtain the transition metal salt solution adding complexing agent;

[0112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com