Special dispersant for hydraulic overflow classification for high-purity superfine silicon carbide micro powder for linear cutting and using method

A silicon carbide micropowder and wire cutting technology, which is applied in the field of high-purity ultrafine silicon carbide micropowder hydraulic overflow grading special dispersant, can solve the problems that it is difficult to meet the needs of the wire cutting industry, silicon carbide particles cannot be dispersed, and the product particle size distribution is wide. Achieve the effect of worsening rheology, low cost, and optimizing rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Prepare the special dispersant for high-purity ultrafine silicon carbide micropowder hydraulic overflow classification of wire cutting according to the following steps

[0057] a. Preparation of Tetramethylammonium Hydroxide 25% aqueous solution

[0058] Dissolve 5 kilograms of industrial product tetramethylammonium hydroxide in an appropriate amount of pure water, and dilute to a concentration of 25% by weight to obtain 20 kilograms of tetramethylammonium hydroxide 25% aqueous solution, or directly purchase a concentration of 25 percent from the market. % tetramethylammonium hydroxide solution, standby;

[0059] b. Preparation of the remaining component aqueous solution

[0060] According to the formula, put 55 kg of pure water, 10 kg of ethanolamine, 6 kg of EDTA, 10 kg of fatty alcohol polyoxyethylene ether O-25, 2 kg of alkylphenol polyoxyethylene ether, and 2 kg of Kason into the mixing tank, stir and dissolve at room temperature 30-60 minutes, spare;

[0061]c....

Embodiment 2~ Embodiment 6

[0064] According to the method and steps of Example 1, according to the ingredients in Table 1, the high-purity ultrafine silicon carbide micropowder hydraulic overflow classification special dispersant for wire cutting of the present invention is prepared

[0065] Table 1

[0066] raw material

[0067] 5-Chloro-2-methyl-4-isothiazolin-3-one

Embodiment 7

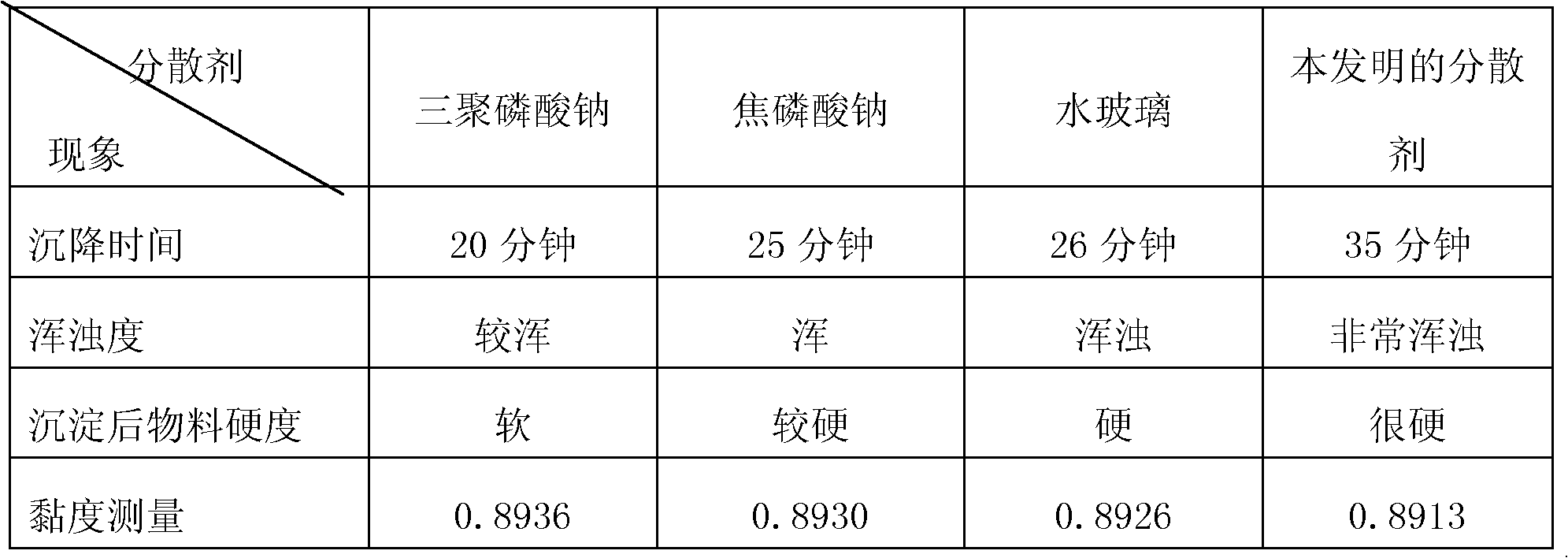

[0069] The dispersants prepared in Examples 1 to 6 are compared with dispersants such as sodium pyrophosphate, sodium tripolyphosphate, and water glass in the laboratory, and the test method is configured according to a concentration of 30% in a graduated beaker A good silicon carbide micropowder aqueous solution, then add the same amount of dispersant to the system, and stir well, observe the following phenomenon:

[0070]

[0071] Settling time refers to the time required for the same material to settle to a certain scale in a graduated beaker.

[0072] Turbidity refers to the same concentration of material settling time, the contrast of turbidity of the system and the contrast of material settling distance.

[0073] The hardness of the material after precipitation refers to the hardness of the settled material after the material has settled.

[0074] When measuring the viscosity, use a viscometer to measure the viscosity of the system at a constant temperature of 25°C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com