Method for preparing calcium carbonate powder

A technology of calcium carbonate powder and carbon dioxide, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of high impurity content in calcium carbonate products, large particle size of calcium carbonate particles, difficult to control crystal form, etc. The effect of uniform particle size and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

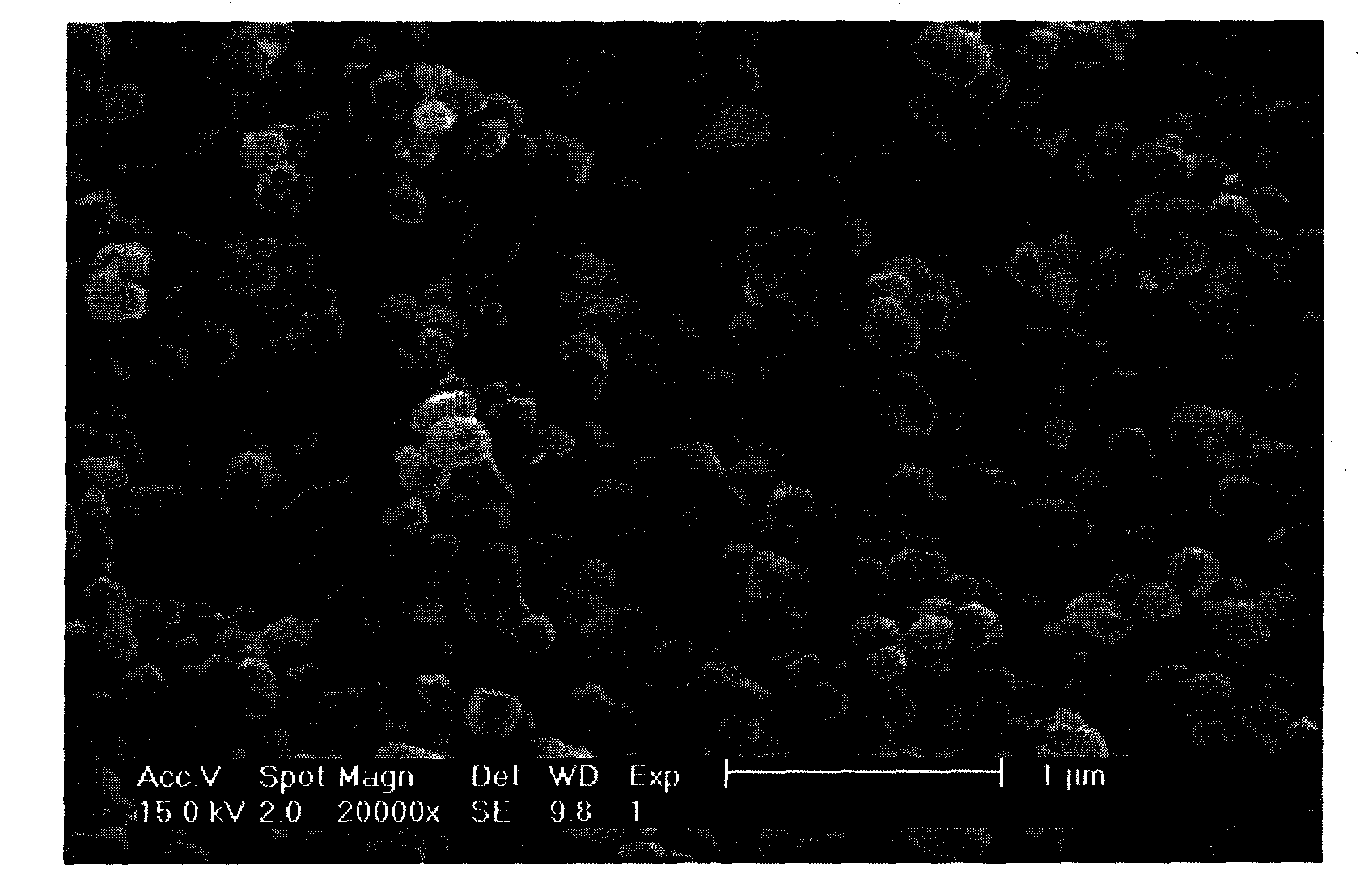

Embodiment 1

[0013] A method for preparing calcium carbonate powder, the steps are: A. Add a calcium oxide impurity remover to the calcium chloride solution, the weight of which is 0.1-0.2% of the weight of calcium chloride; heat to 80±5°C while stirring, And keep this temperature for 20±5min, then let it stand to cool to within 50℃, and filter the solution into the reaction kettle; B. Add sodium hydroxide solution with a molar ratio of 1.3-1.5 to the solution obtained in step A, and the addition is complete Stirring after circulation; C. Pour carbon dioxide into the solution of step B under agitation to carry out the carbonization reaction. During the carbonization process, control the reaction temperature to 22±2°C until PH=7 to stop the reaction, and finally filter, wash, Calcium carbonate powder is obtained by drying. The adding speed of the sodium hydroxide solution in step B is 67ml±5 / min, and the circulation stirring time is 10±5min. In the step C, the total flow of carbon dioxide is co...

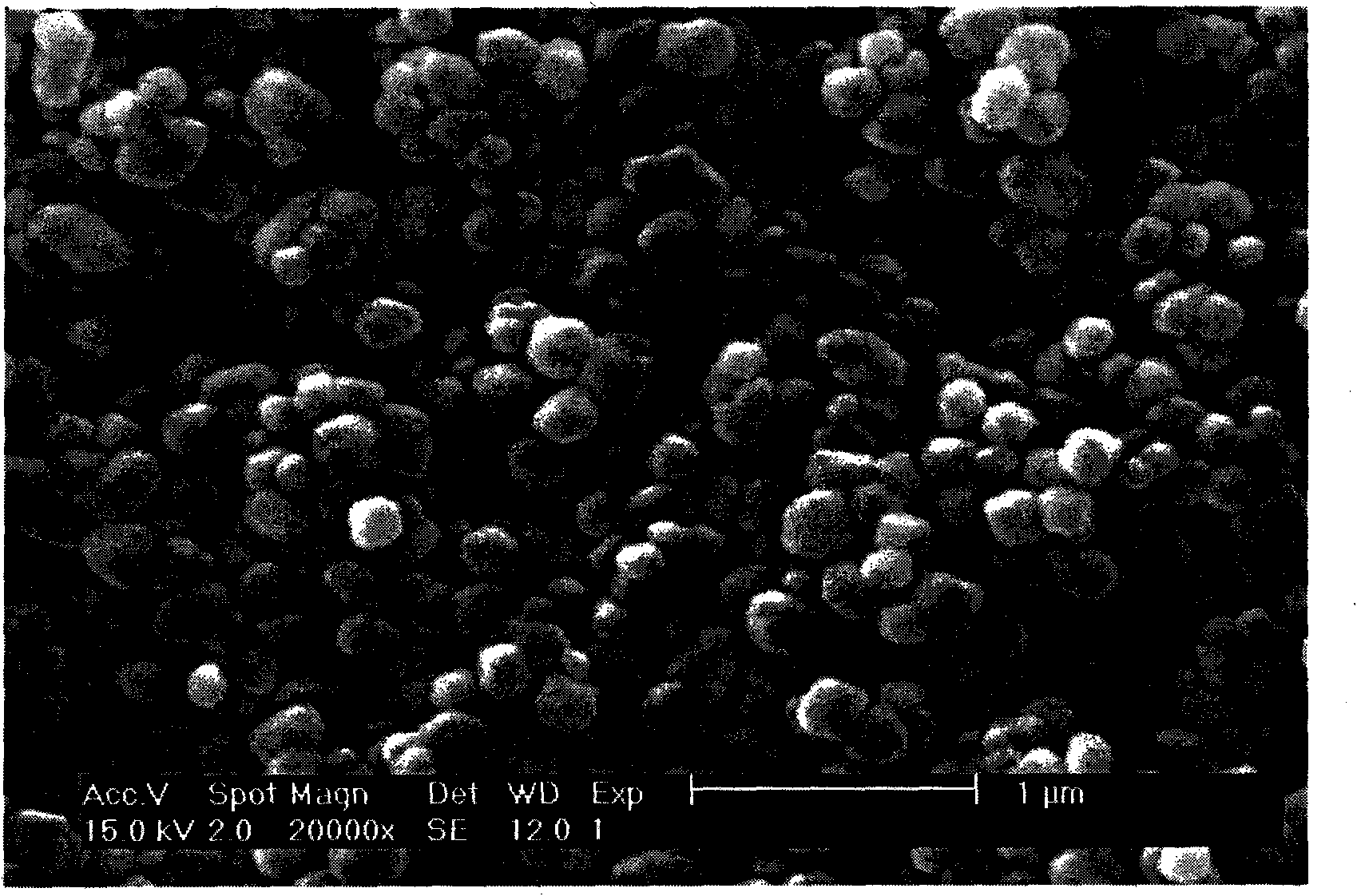

Embodiment 2

[0015] A method for preparing calcium carbonate powder, the steps are: A. Add calcium hydroxide impurity remover to the calcium chloride solution, the weight of which is 0.1-0.2% of the weight of calcium chloride; heating to 80±5°C while stirring , And keep this temperature for 20±5min, then let it stand to cool to within 50℃, filter the solution into the reaction kettle; B. Add sodium hydroxide solution with a molar ratio of 1.3-1.5 to the solution obtained in step A, add Cycling stirring after the completion; C. Pour carbon dioxide into the solution of step B under stirring to carry out the carbonization reaction. During the carbonization process, control the reaction temperature to 30±2°C until the PH=7 to stop the reaction, and finally filter and wash , Dry to obtain calcium carbonate powder. The adding speed of the sodium hydroxide solution in step B is 67ml±5 / min, and the circulation stirring time is 10±5min. In the step C, the total flow of carbon dioxide is controlled at 8...

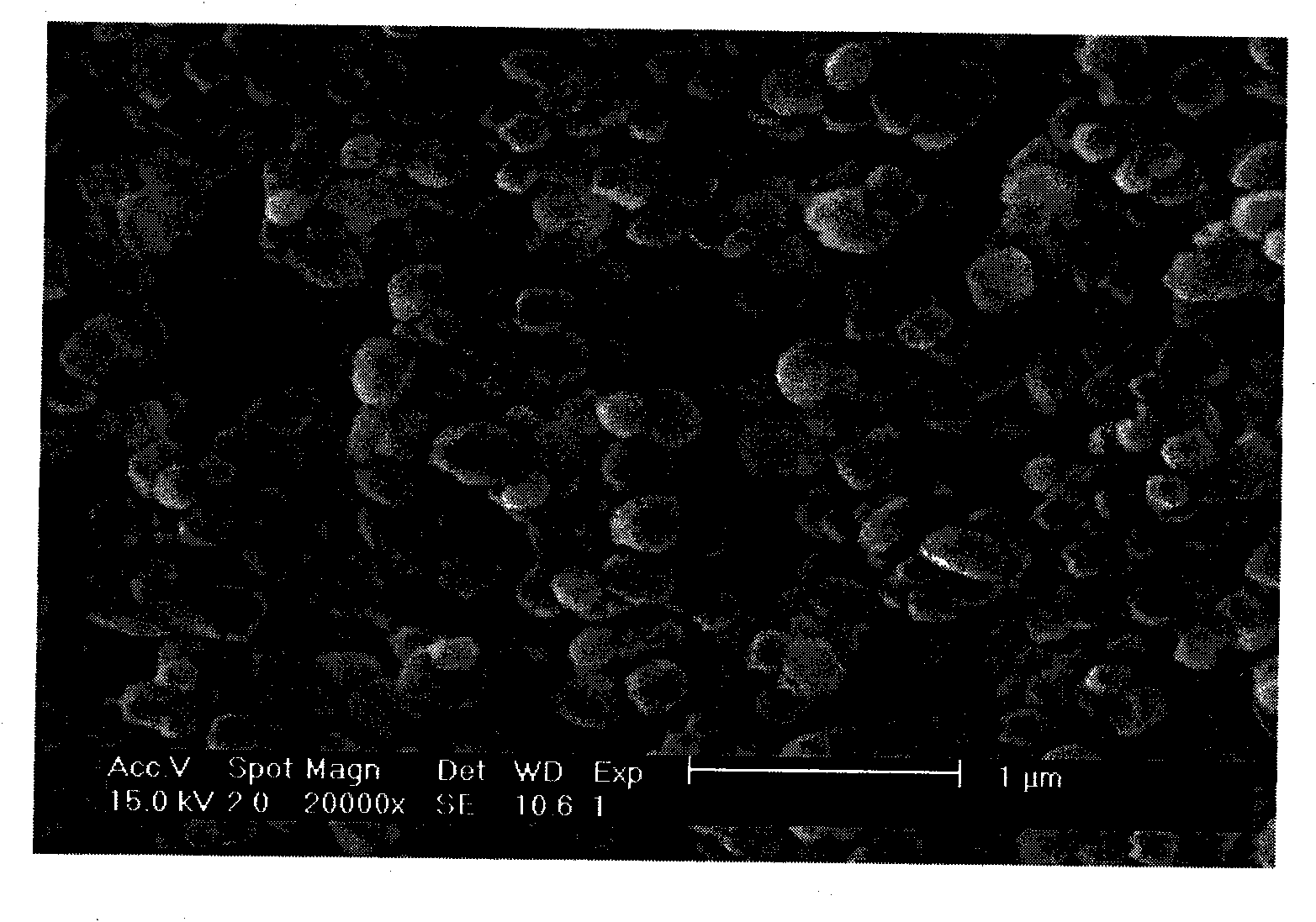

Embodiment 3

[0017] A method for preparing calcium carbonate powder, the steps are: A. Add calcium oxide and calcium hydroxide impurity remover to the calcium chloride solution, the weight of which is 0.1-0.2% of the weight of calcium chloride; heating to 80% while stirring ±5℃, and keep this temperature for 20±5min, then let stand and cool to within 50℃, filter the solution into the reaction kettle; B. Add sodium hydroxide solution with a molar ratio of 1.3-1.5 to the solution obtained in step A After the addition is complete, circulate and stir; C. Pour carbon dioxide into the solution of step B under stirring to carry out the carbonization reaction. During the carbonization process, control the reaction temperature to 38±2°C until the PH=7 to stop the reaction. Filter, wash, and dry to obtain calcium carbonate powder. The adding speed of the sodium hydroxide solution in step B is 67ml±5 / min, and the circulation stirring time is 10±5min. In the step C, the total flow of carbon dioxide is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com