Discharge method of waste lithium battery

A waste lithium battery and battery technology, which is applied in secondary battery charging/discharging, secondary battery, secondary battery repair/maintenance, etc., can solve problems such as difficult large-scale application, easy oxidation, unstable ascorbic acid, etc., and achieve The discharge conditions are easy to control, the discharge cost is saved, and the ion concentration is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

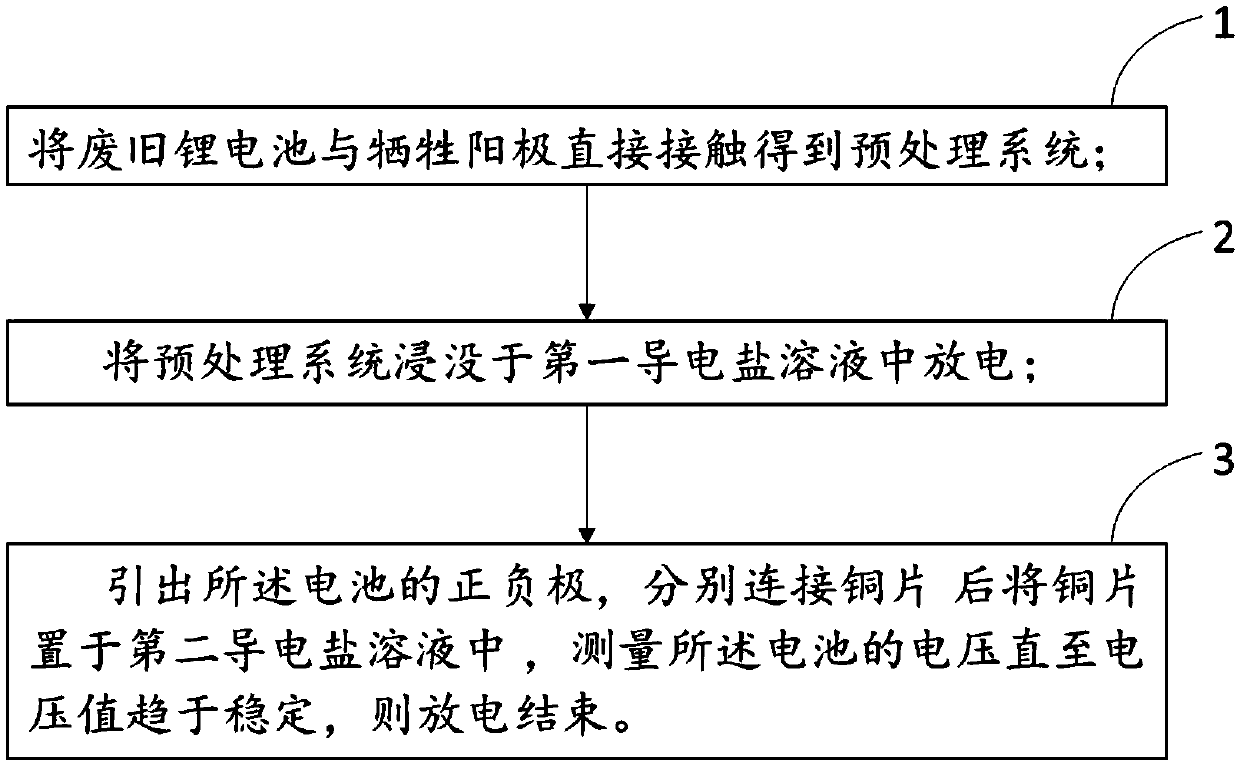

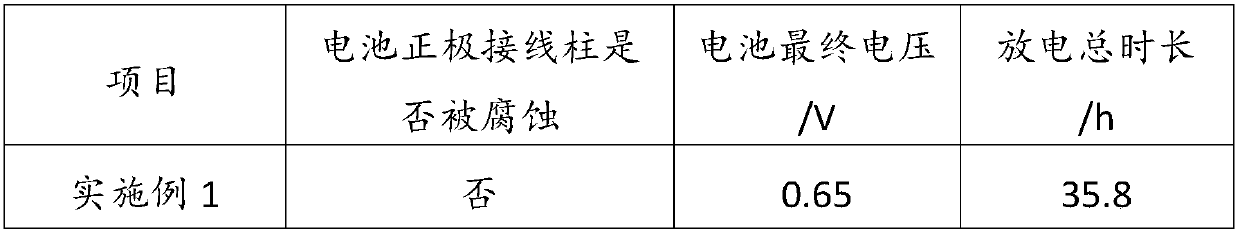

[0050] (1) The positive terminal of the waste lithium ion battery is directly contacted with the hollow circular magnesium, and the mass ratio of magnesium to the waste lithium ion battery is 1:150.

[0051] (2) Discharge the waste lithium-ion battery obtained in step (1) by immersing it in a magnesium chloride solution (the first conductive salt solution). The mass concentration of the magnesium chloride solution is 10%, and the discharge time is 16 hours.

[0052] (3) lead out the positive and negative poles of the waste lithium-ion battery that step (2) obtains, and connect with the copper sheet respectively, then put the copper sheet into a magnesium chloride solution (the second conductive salt solution) that the mass concentration is 10% During the process of battery discharge, the voltage change with time is measured immediately, and the discharge time is recorded when the voltage becomes stable (that is, the voltage value does not change within half an hour), and the di...

Embodiment 2

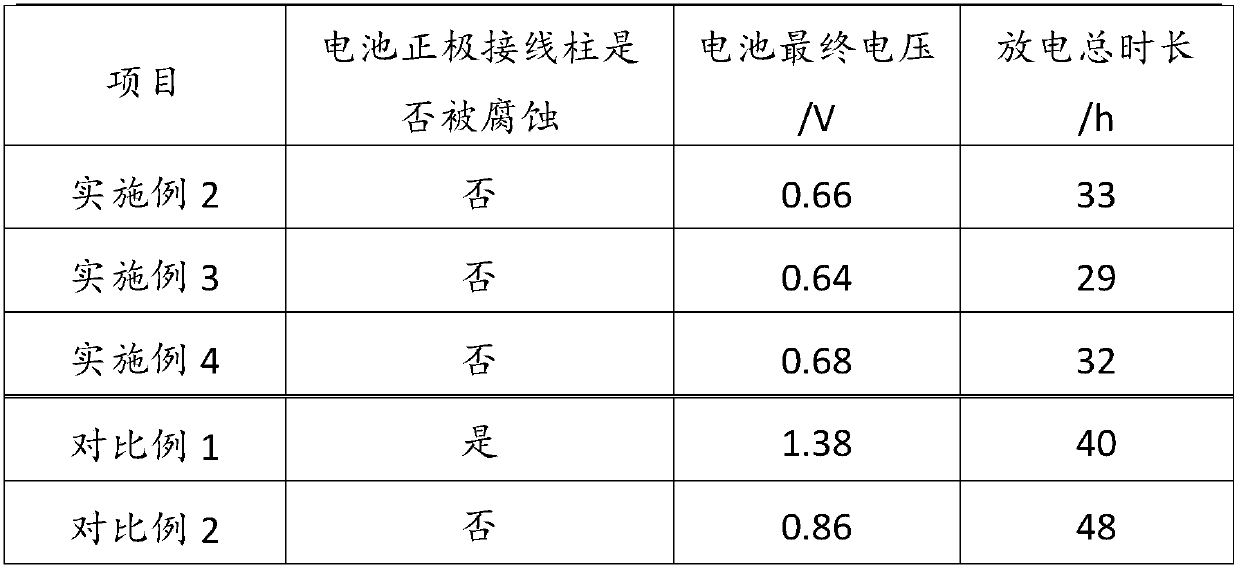

[0055] (1) The positive terminal of the waste lithium ion battery is directly contacted with the hollow circular magnesium, and the mass ratio of magnesium to the waste lithium ion battery is 1:250.

[0056] (2) Discharge the waste lithium-ion battery obtained in step (1) by immersing it in a magnesium chloride solution (the first conductive salt solution). The mass concentration of the magnesium chloride solution is 10%, and the discharge time is 16 hours.

[0057] (3) lead out the positive and negative poles of the waste lithium-ion battery that step (2) obtains, and connect with the copper sheet respectively, then put the copper sheet into a magnesium chloride solution (the second conductive salt solution) that the mass concentration is 10% During the process of battery discharge, the voltage change with time is measured immediately, and the discharge time is recorded when the voltage becomes stable (that is, the voltage value does not change within half an hour), and the di...

Embodiment 3

[0060] (1) The positive terminal of the waste lithium ion battery is directly contacted with the hollow circular magnesium, and the mass ratio of magnesium to the waste lithium ion battery is 1:350.

[0061] (2) Discharge the waste lithium-ion battery obtained in step (1) by immersing it in a magnesium chloride solution (the first conductive salt solution). The mass concentration of the magnesium chloride solution is 10%, and the discharge time is 16 hours.

[0062] (3) lead out the positive and negative poles of the waste lithium-ion battery that step (2) obtains, and connect with the copper sheet respectively, then put the copper sheet into a magnesium chloride solution (the second conductive salt solution) that the mass concentration is 10% During the process of battery discharge, the voltage change with time is measured immediately, and the discharge time is recorded when the voltage becomes stable (that is, the voltage value does not change within half an hour), and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com