Re-alsic-rare-earth-aluminum-silicon-carbide-based LED rare earth thick film circuit electric light source device

A rare earth thick film, silicon carbide-based technology, applied in the field of high-efficiency and high-power LED electric light source components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

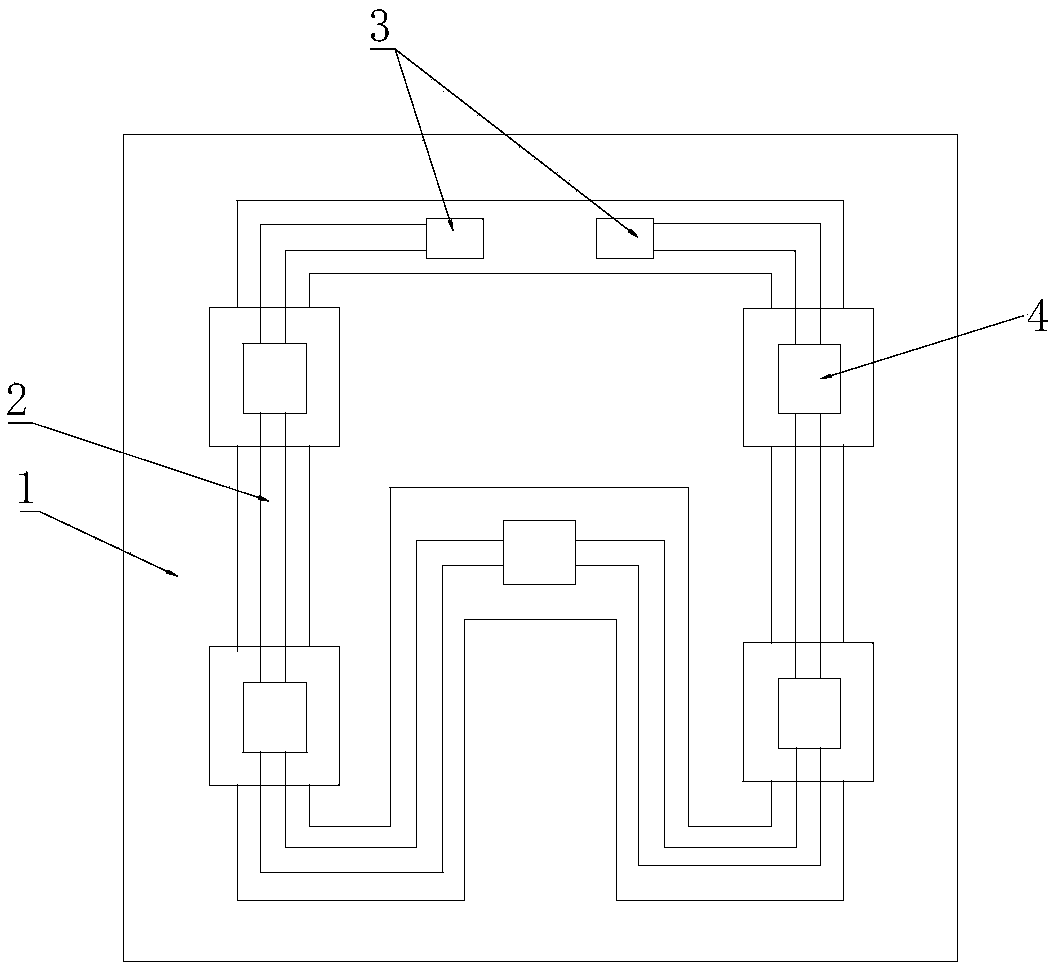

Image

Examples

preparation example Construction

[0060] The preparation process of the rare earth medium slurry includes:

[0061] 1) Preparation of glass-ceramic powder

[0062] Mix the well-proportioned glass-ceramic powder evenly in a mixer and put it in a bell furnace for melting; the melting temperature is 800-1200 degrees Celsius, the peak temperature is kept for 1-5 hours, and the glass slag is obtained by water quenching; the glass slag is As for grinding in a planetary ball mill for 2 to 4 hours to obtain glass powder with an average particle size not greater than 5 microns;

[0063] 2) Preparation of inorganic binder phase and organic solvent carrier

[0064] The preparation of the inorganic adhesive phase and the organic solvent carrier is to dissolve the main solvent, thickener, surfactant, thixotropic agent, and gelling agent in the organic solvent carrier in water at 80-100°C for several hours, and adjust the increase Thickener, diluent content, just adjust the viscosity of the organic solvent carrier within ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com