IGBT (insulated gate bipolar transistor) modular structure

A module structure and cavity technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of poor controllability, complicated process, and no reduction of the electric field intensity at the maximum value of the electric field, so as to improve the discharge performance and reduce the Electric field strength, the effect of avoiding partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

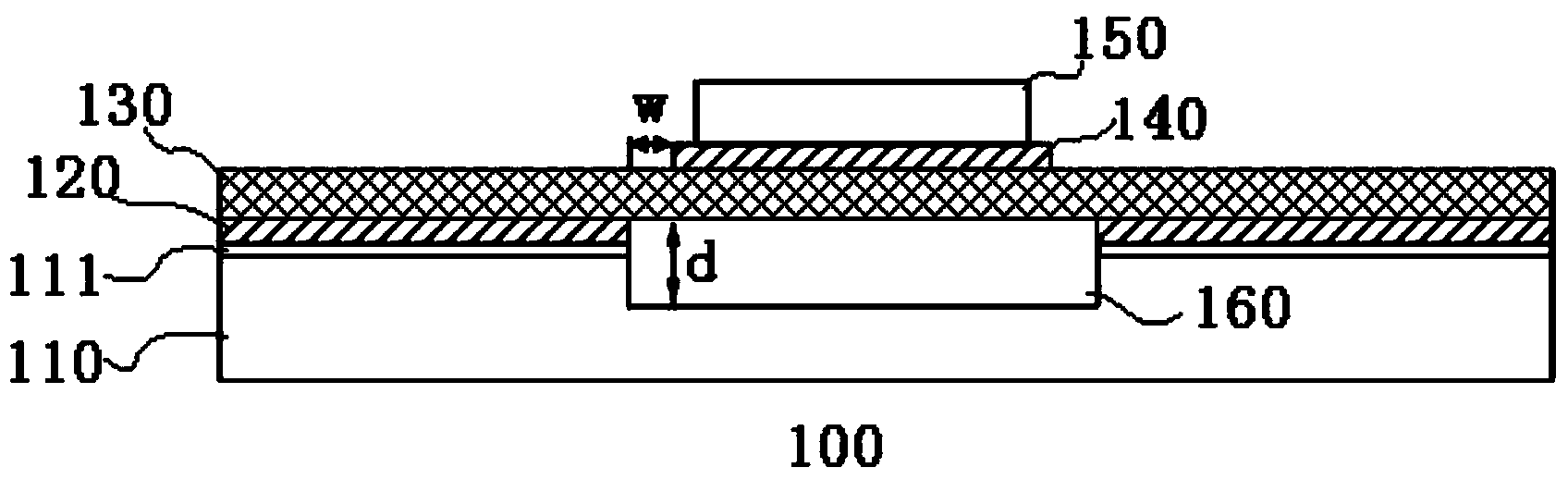

[0028] As mentioned in the background art, in the existing IGBT modules, in order to improve the partial discharge performance of the IGBT modules, new insulating materials are often used to improve their ability to withstand electric fields. However, this method not only leads to an increase in the complexity of the manufacturing process, but also fails to fundamentally improve the partial discharge performance of the module because it fails to reduce the electric field intensity at the maximum value of the electric field of the module.

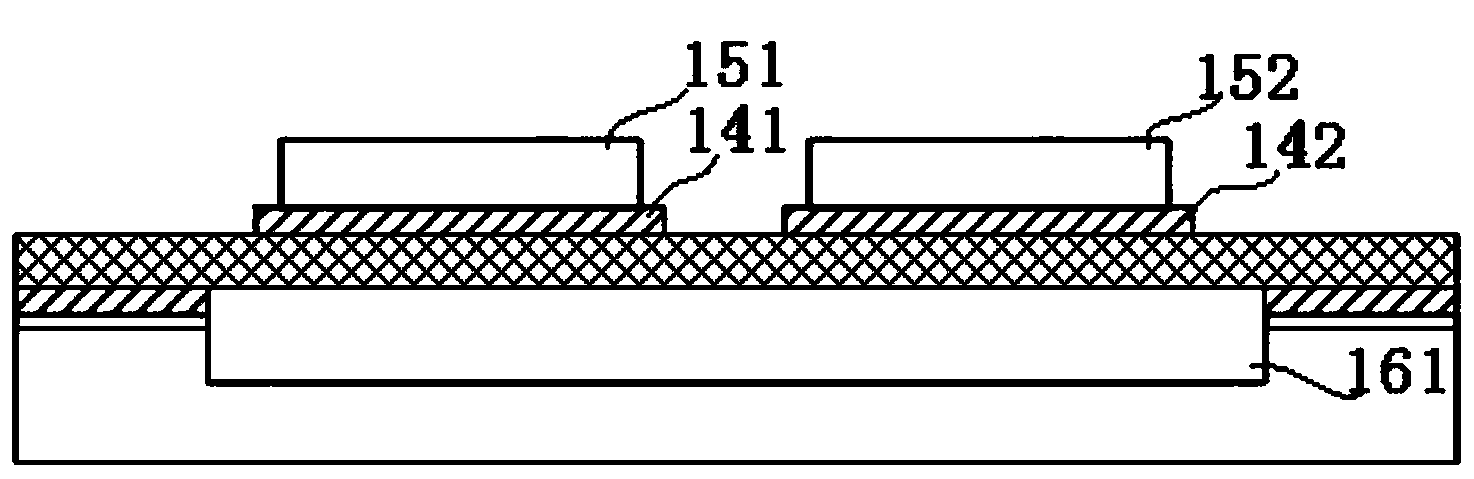

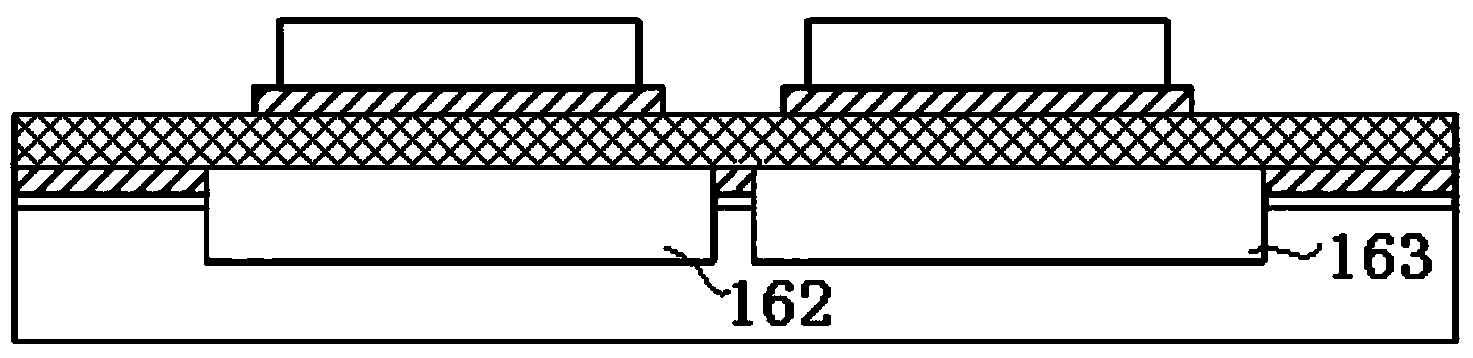

[0029] Therefore, the present invention proposes a new IGBT module structure from the perspective of changing the structure and optimizing the process. By setting a cavity below the chip, the electric field intensity at the maximum value of the electric field is reduced, and the local discharge of the TV is reduced. Avoid partial discharge and improve the discharge performance of the module.

[0030] The technical scheme of this case will be intr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com